High-strength extra-high-voltage spring contact finger and processing technology thereof

A spring contact finger and processing technology, which is applied in the manufacture of tools, contact parts, contact parts, etc., can solve the problems affecting the normal use of the spring contact finger, the strength and elasticity of the spring contact finger, etc., to improve the effect of precipitation hardening, Guaranteed high strength and elastic properties, the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention provides a high-strength ultra-high voltage spring contact finger, which includes: 0.40% beryllium, 2.40% cobalt, 1.80% nickel, 0.30% rare earth silicon aluminum alloy, the sum of impurities < 0.05%, and the rest It is copper; the rare earth silicon aluminum alloy includes: 0.94% rare earth lanthanum, 0.02% silicon, 9.60% titanium, and 89.44% aluminum in terms of weight percentage;

[0026] A processing technology for a high-strength ultra-high voltage spring contact finger, the specific processing steps are as follows:

[0027] Step 1: weighing the rare earth lanthanum, silicon, titanium, and aluminum in the raw materials of beryllium, cobalt, nickel, copper, and rare earth silicon-aluminum alloy according to the above weight ratio;

[0028] Step 2: Vacuum smelt the beryllium, cobalt, nickel, and copper in step 1, then add the rare earth silicon-aluminum alloy in step 1, melt and blend, keep warm for 60-90 minutes, cast and anneal, and make spring contact...

Embodiment 2

[0034] The difference from Example 1 is that it includes: 0.70% beryllium, 2.70% cobalt, 2.40% nickel, 0.50% rare earth silicon aluminum alloy, the sum of impurities < 0.05%, and the rest is copper; the rare earth The silicon-aluminum alloy includes: 1.04% of rare earth lanthanum, 0.04% of silicon, 10.60% of titanium, and 88.32% of aluminum in terms of weight percentage.

Embodiment 3

[0036] The difference from Examples 1-2 is that it includes: 0.55% beryllium, 2.55% cobalt, 2.10% nickel, 0.40% rare earth silicon aluminum alloy, the sum of impurities < 0.05%, and the rest is copper; The rare earth silicon aluminum alloy includes: 0.99% rare earth lanthanum, 0.03% silicon, 10.10% titanium, and 88.88% aluminum according to weight percentage.

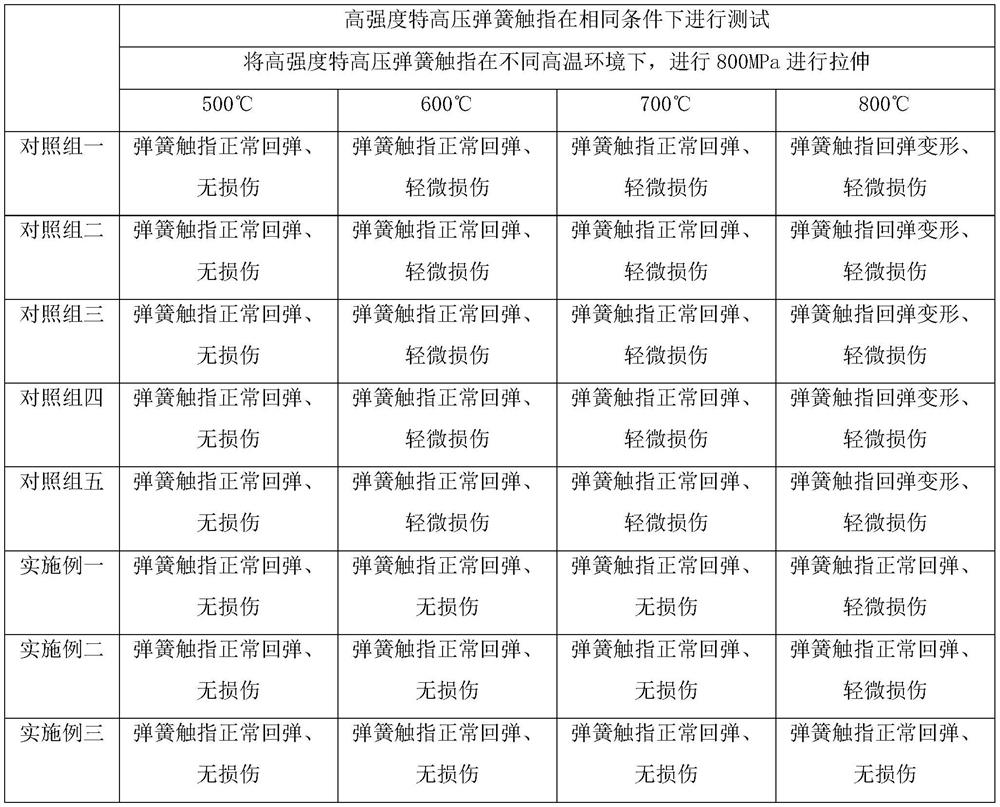

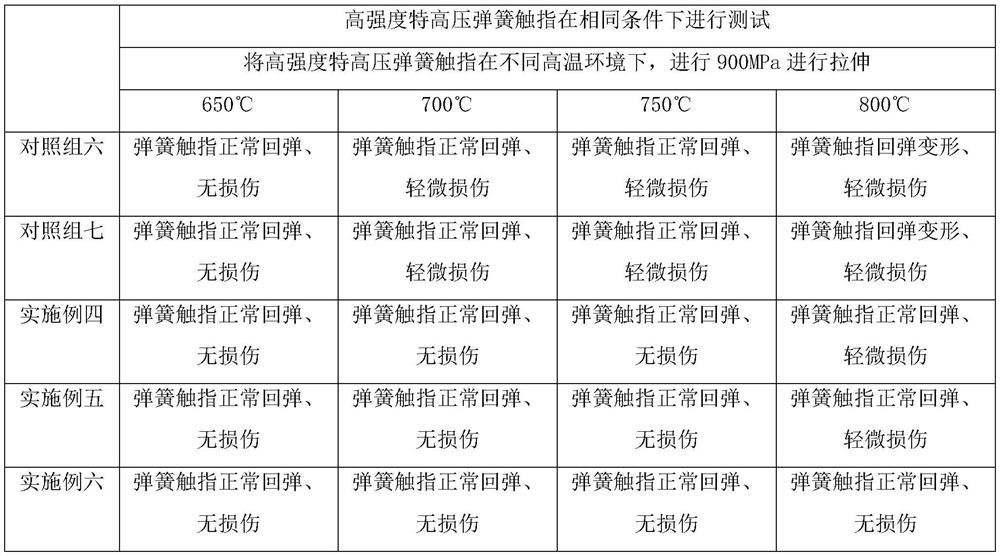

[0037]Take the high-strength UHV spring contact finger prepared in the above-mentioned Examples 1-3 and the high-strength UHV spring contact finger of the control group 1, the high-strength UHV spring contact finger of the control group 2, and the high-strength UHV spring contact finger of the control group 3. The UHV spring contact finger, the high-strength UHV spring contact finger of control group 4 and the high-strength UHV spring contact finger of control group 5, the high-strength UHV spring contact finger of control group 1 has no nickel compared with Example 3, Compared with Example 3, the high-strength UHV spri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com