Production process of antibacterial nanofiber yarns

A nanofiber and production process technology, which is applied in the field of antibacterial material preparation, can solve the problems of high preparation cost, general antibacterial effect of antibacterial yarn, and poor antibacterial persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention discloses a production process of antibacterial nanofiber yarn, specifically comprising the following steps: sequentially performing cleaning, carding, combing, drawing, roving and spun antibacterial fiber, cotton fiber and nylon fiber to prepare antibacterial nanofiber yarn.

[0030] Antibacterial fiber is made by the following steps:

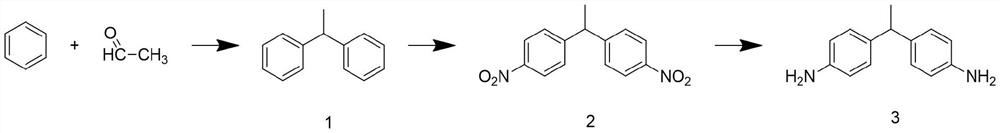

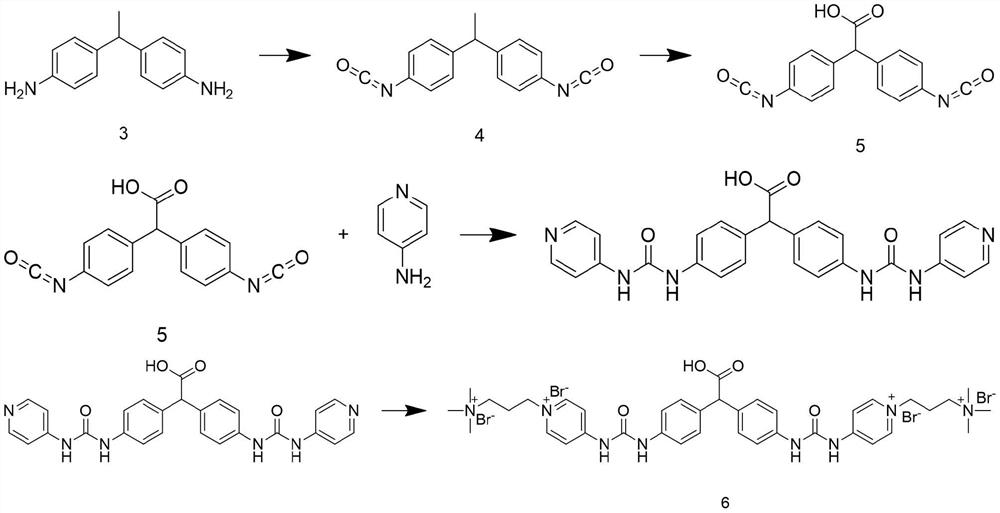

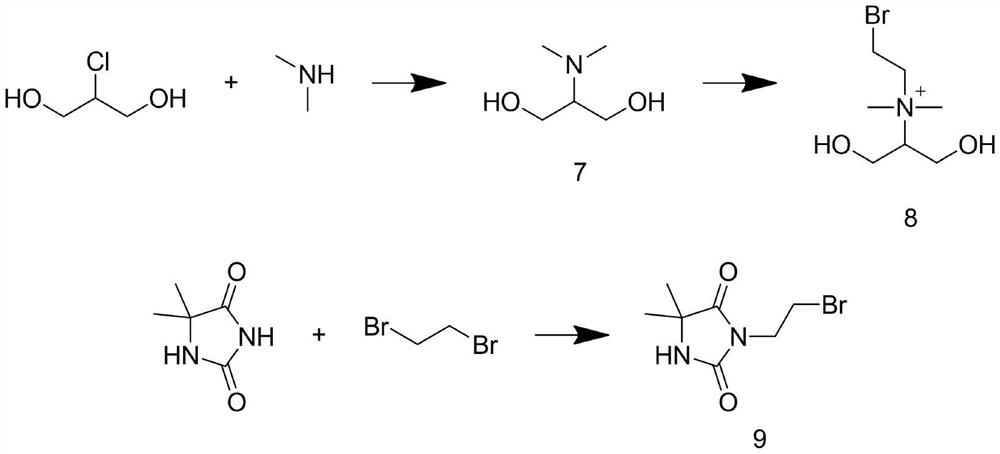

[0031] Step A1: Mix benzene and aluminum trichloride evenly, stir at a speed of 150r / min and a temperature of 18°C, add acetaldehyde, and react for 4 hours to obtain intermediate 1, and add intermediate 1 to In the reaction kettle, under the condition that the rotation speed is 200r / min and the temperature is 50°C, stir and add mixed acid dropwise, and react for 1h to obtain intermediate 2. Mix intermediate 2, tin and concentrated hydrochloric acid evenly, and Under the conditions of 150r / min and 100°C, the reaction was carried out for 30 minutes, and the pH value of the reaction solution was adjusted to be alkaline to obt...

Embodiment 2

[0037] The invention discloses a production process of antibacterial nanofiber yarn, specifically comprising the following steps: sequentially performing cleaning, carding, combing, drawing, roving and spun antibacterial fiber, cotton fiber and nylon fiber to prepare antibacterial nanofiber yarn.

[0038] Antibacterial fiber is made by the following steps:

[0039] Step A1: Mix benzene and aluminum trichloride evenly, stir at a speed of 180r / min, and a temperature of 20°C, add acetaldehyde, and react for 5 hours to obtain intermediate 1, and add intermediate 1 to In the reaction kettle, under the condition that the rotation speed is 300r / min and the temperature is 53°C, stir and add mixed acid dropwise, and react for 1.5h to obtain intermediate 2, mix intermediate 2, tin, and concentrated hydrochloric acid evenly, and place in The rotating speed is 180r / min, and the temperature is 105°C. After the reaction is carried out for 35 minutes, the pH value of the reaction solution is...

Embodiment 3

[0045] The invention discloses a production process of antibacterial nanofiber yarn, specifically comprising the following steps: sequentially performing cleaning, carding, combing, drawing, roving and spun antibacterial fiber, cotton fiber and nylon fiber to prepare antibacterial nanofiber yarn.

[0046] Antibacterial fiber is made by the following steps:

[0047] Step A1: Mix benzene and aluminum trichloride evenly, stir at a speed of 200r / min and a temperature of 22°C, add acetaldehyde, and react for 5 hours to obtain intermediate 1, and add intermediate 1 to In the reaction kettle, under the condition that the rotation speed is 300r / min and the temperature is 55°C, stir and add mixed acid dropwise, and react for 2 hours to obtain intermediate 2. Mix intermediate 2, tin and concentrated hydrochloric acid evenly, and Under the conditions of 200r / min and 110°C, the reaction was carried out for 40 minutes, and the pH value of the reaction solution was adjusted to be alkaline t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com