Preparation method and application of composite pipe

A technology of composite pipe and composite layer, which is applied in the field of composite pipe, can solve the problems of complex production process, poor bonding force between the composite layer and the base layer, and poor bonding strength, and achieve the effects of high dimensional accuracy, smooth surface, and high bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0098] The preparation methods of traditional metal composite pipes include metallurgical fusion composite method, explosive forming method and nested forming composite method.

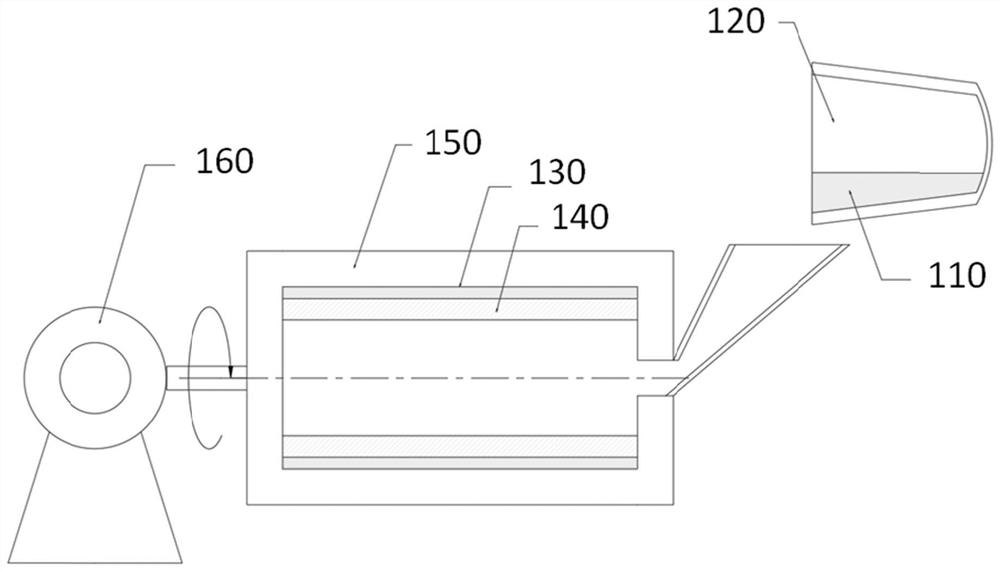

[0099] The principle of metallurgical fusion composite method is as follows: figure 1 As shown: Specifically, the cladding material blank is first melted into molten metal 110 in the electric furnace ladle 120, cast into the mold 150, driven by the motor 160 to rotate at high speed, and the molten metal 110 is cooled to form a tubular outer shell under the action of centrifugal force. layer 130, and then repeat the above steps with the raw material of the base material to form a metallurgically fused composite pipe of the outer layer 130 and the inner layer 140.

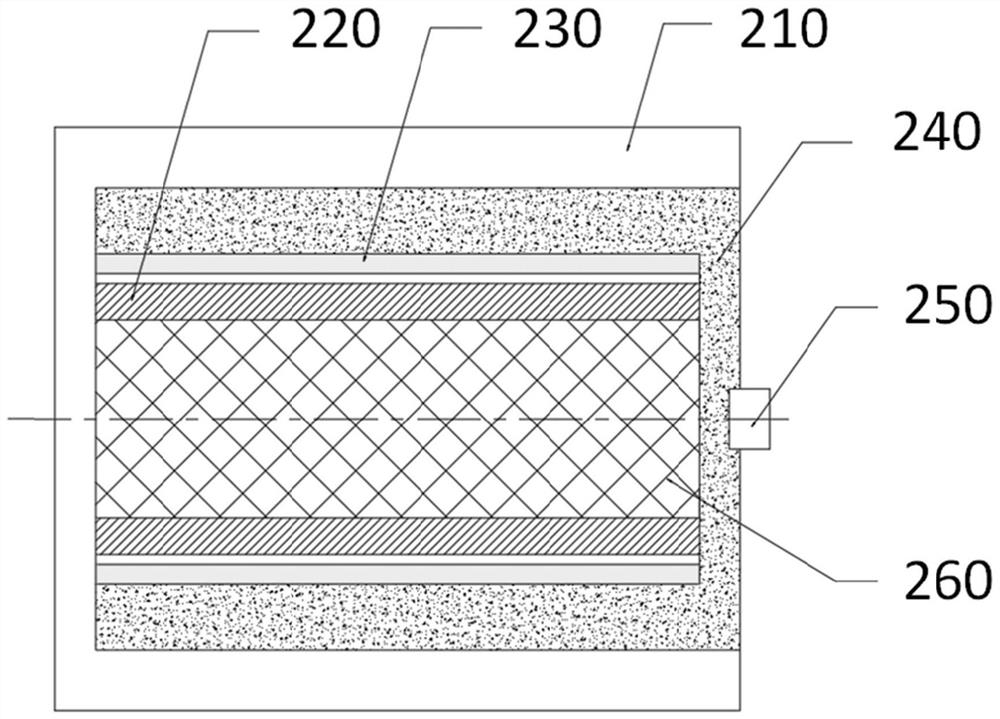

[0100] Schematic diagram of the technological process of the explosive molding method. figure 2 As shown, specifically, the composite layer 230 pipe (raw material) with a slightly larger outer diameter is inserted into the outside of the b...

Embodiment 1

[0107] This embodiment has prepared a kind of composite pipe, and specific process is:

[0108] S1. Base tube preparation: the base tube is 20G;

[0109] S2. Determination and preparation of the parameters of the composite layer: determine that the design diameter of the composite pipe obtained is The length is 10m, the wall thickness of the composite layer is ≥2mm, and the material of the composite layer is Inconel625;

[0110] according to Figure 5 Surfacing welding is carried out in the schematic diagram shown, specifically, the cladding layer 480 is welded on the base pipe 470;

[0111] During the surfacing welding process, the welding torch 430 is stabilized under the action of the welding torch holder 440, and the welding wire 420 is melted by the welding torch 430 under the control of the welding machine 410, and is surfacing welded to the outer surface of the base pipe 470, wherein the welding wire 420 has a diameter of The solid welding wire (model ERNiCrMo-3), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com