Coated ternary precursor, preparation method thereof and positive electrode material containing coated ternary precursor

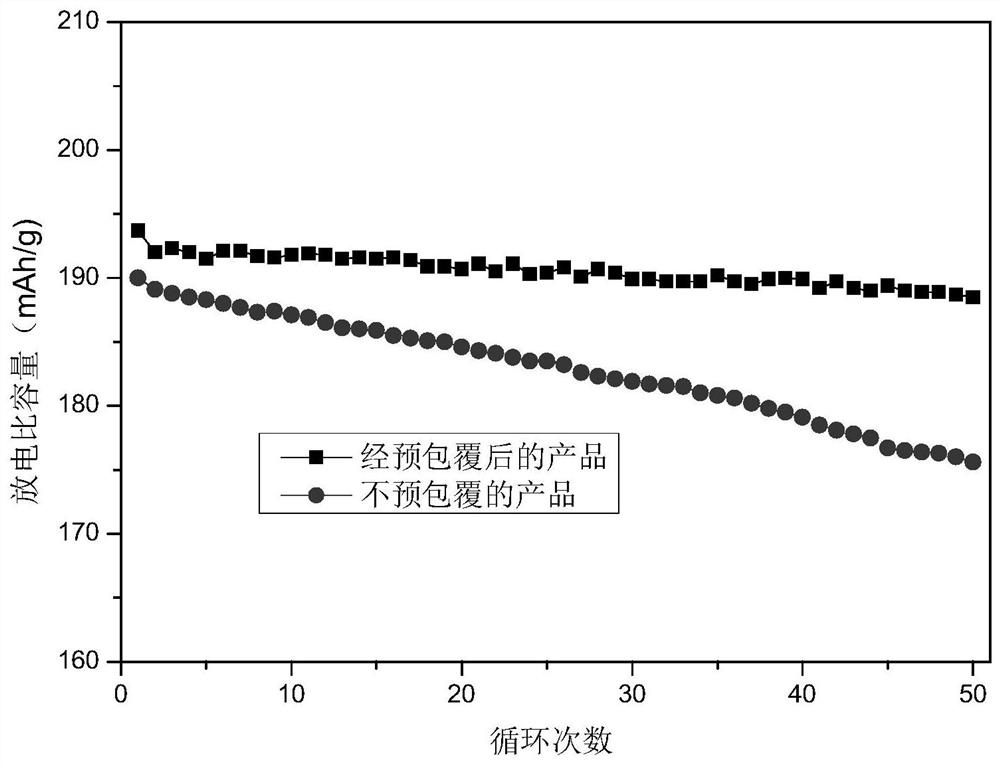

A technology of positive electrode materials and precursors, applied in the direction of electrical components, battery electrodes, electrochemical generators, etc., can solve problems such as microcracks and affect cycle performance, and achieve the effect of improving stability, improving cycle performance, and avoiding microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

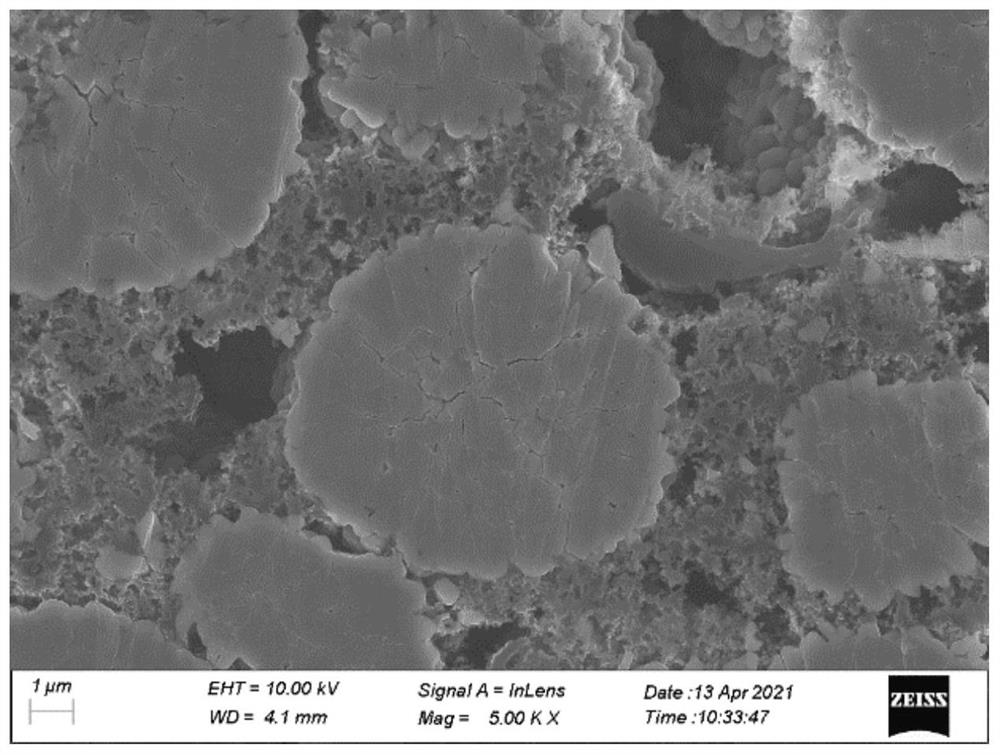

[0053] This embodiment provides a method for preparing a coated ternary precursor, including the following steps:

[0054] Step S1: Take the ternary precursor (molecular formula: Ni 0.62 mn 0.2 co 0.18 (OH) 2 ) into a 20wt% ammonia solution heated in a water bath, control the mass ratio of the water in the ammonia solution to the ternary precursor to 3:2, the temperature of the water bath is 35°C, stir for 30min at a speed of 300rpm, and the ternary precursor Dissolve evenly to obtain a precursor solution. Dissolve zirconium sulfate in ethanol, control the ratio of the mass of ethanol to the mass of ammonia water to be 1:1, the content of zirconium in zirconium sulfate accounts for 1000ppm of the mass of the ternary precursor, stir in a water bath at 40°C and 300rpm for 8h, and obtain the package Overlay.

[0055] Step S2: Add the coating liquid into the precursor solution, stir in a water bath at 50° C. and 300 rpm for 30 min to achieve full hydrolysis coating, and obtai...

Embodiment 2

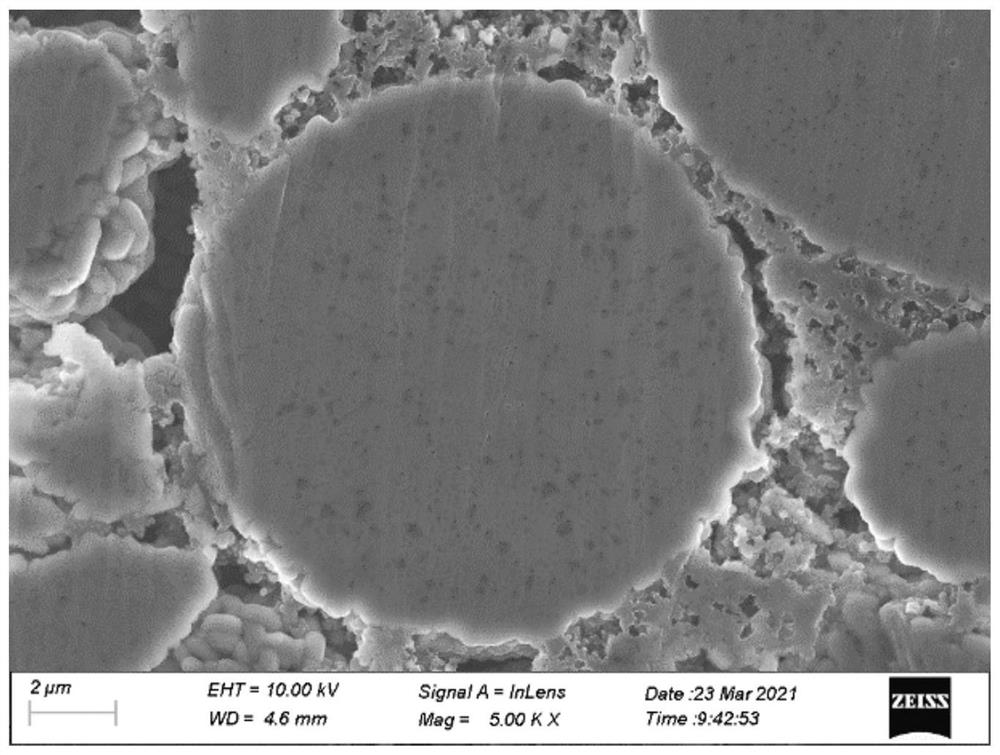

[0062] This embodiment provides a method for preparing a coated ternary precursor, including the following steps:

[0063] Step S1: Take the ternary precursor (molecular formula: Ni 0.62 mn 0.2 co 0.18 (OH) 2 Put it into a 20wt% ammonia solution heated by a water bath, control the mass ratio of the water in the ammonia solution to the ternary precursor to 3:2, the temperature of the water bath is 35°C, stir for 30min at a speed of 300rpm, and the ternary precursor is uniform dissolved to obtain a precursor solution. Dissolve aluminum sulfate and titanium sulfate in ethanol, and control the ratio of the mass of ethanol to the mass of ammonia water to be 1:1. The content of aluminum in aluminum sulfate accounts for 1000ppm of the mass of the ternary precursor, and the content of titanium in titanium sulfate accounts for 1000ppm of the mass of the ternary precursor. The body mass was 1000 ppm, stirred in a water bath at 40° C. and 300 rpm for 8 hours to obtain a coating solut...

Embodiment 3

[0071] This embodiment provides a method for preparing a coated ternary precursor, including the following steps:

[0072] Step S1: Take the ternary precursor (molecular formula: Ni 0.85 mn 0.08 co 0.7 (OH) 2 Put it into the aqueous solution of ammonium bicarbonate heated in a water bath (the mass ratio of ammonium bicarbonate to water is 1:4), control the mass ratio of the mass of water to the ternary precursor to 8:1, and the temperature of the water bath is 55°C. Stirring at 800rpm for 60min, the ternary precursor was uniformly dissolved to obtain a precursor solution. Dissolve aluminum sulfate and titanium sulfate in ethanol, and control the ratio of the mass of ethanol to the mass of ammonia water to be 1:1. The content of aluminum in aluminum sulfate accounts for 20000ppm of the mass of the ternary precursor, and the content of titanium in titanium sulfate accounts for 20000ppm of the mass of the ternary precursor. 30,000 ppm by weight, stirred in a water bath at 50°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com