Fermented milk containing Lactobacillus reuteri, and preparation method of fermented milk

A technology of Lactobacillus reuteri and fermented milk, which is applied in the field of fermented milk containing Lactobacillus reuteri and its preparation, can solve the problems of loose texture, unsatisfactory stability of fermented milk, serious water separation, etc., and achieve water retention Good, smooth and rich taste, simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Get the Lactobacillus reuteri J1 (Lactobacillus reuteri J1) preserved at -80 ℃, activate on the culture dish of M17 solid medium containing 5% sucrose, and contain 5wt% sucrose in aseptic skimmed milk step by step Expand cultivation to obtain fermented seed liquid (cultivation temperature 37° C.), and the cultivation time is 24 hours;

[0022] 2) Heat and mix raw materials including the following weight percentages: 90% fresh milk, 10% white sugar, heating temperature is 40°C, homogenize while hot (20MPa), sterilization treatment, sterilization temperature is 95°C, sterilization time is 30s;

[0023] 3) Inoculate the fermented seed liquid obtained in step 1) to the aseptic fresh milk obtained in step 2), so that the number of colonies of Lactobacillus reuteri J1 reaches 1×10 at the beginning of fermentation. 6 cfu / mL, fermented at 37°C for 6 hours to obtain Lactobacillus reuteri J1 fermented milk.

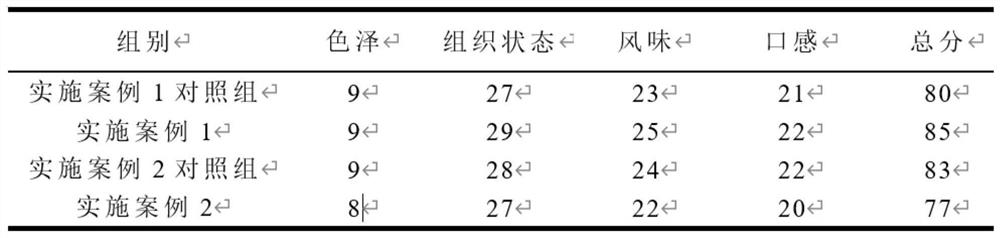

[0024] 4) Produce conventional fermented milk with ordinary technol...

Embodiment 2

[0030] 1) activate Lactobacillus reuteri J1 (Lactobacillus reuteri J1) by the same method as in Example 1 to obtain a fermented seed liquid;

[0031] 2) Heat and mix raw materials including the following weight percentages: fresh milk 82%, white sugar 18%, heating temperature is 45°C; homogenize while hot (15MPa), sterilization treatment, sterilization temperature is 90°C, sterilization time is 30s;

[0032] 3) Inoculate the fermented seed liquid obtained in step 1) into the aseptic fresh milk obtained in the above step 2), so that the number of colonies of Lactobacillus reuteri J1 at the beginning of fermentation reaches 1×10 8 cfu / mL, fermented at 37°C for 8 hours to obtain Lactobacillus reuteri J1 fermented milk.

[0033] 4) Produce conventional fermented milk with ordinary technology: fresh milk (heated to 50°C) + white sugar → high-speed stirring for 20 minutes → heating to 65°C → homogeneous [primary pressure (16) MPa, secondary pressure (3) MPa] → sterilization (95°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inoculation amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com