Low-turbidity precise sewage filtering system and use method thereof

A filtration system, low turbidity technology, applied in filtration treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of inability to filter viscous filtrate high algae sewage, inability to directly filter polluted sewage, and inability to continuously and stably operate and other problems to achieve the effect of enhancing residence time, thorough backwashing, and prolonging time and distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0050] Wherein the same components are denoted by the same reference numerals. It should be noted that the words "top", "bottom", "left", "right", "bottom", "inner" and "outer" used in the following descriptions refer to directions in the drawings, but do not limited.

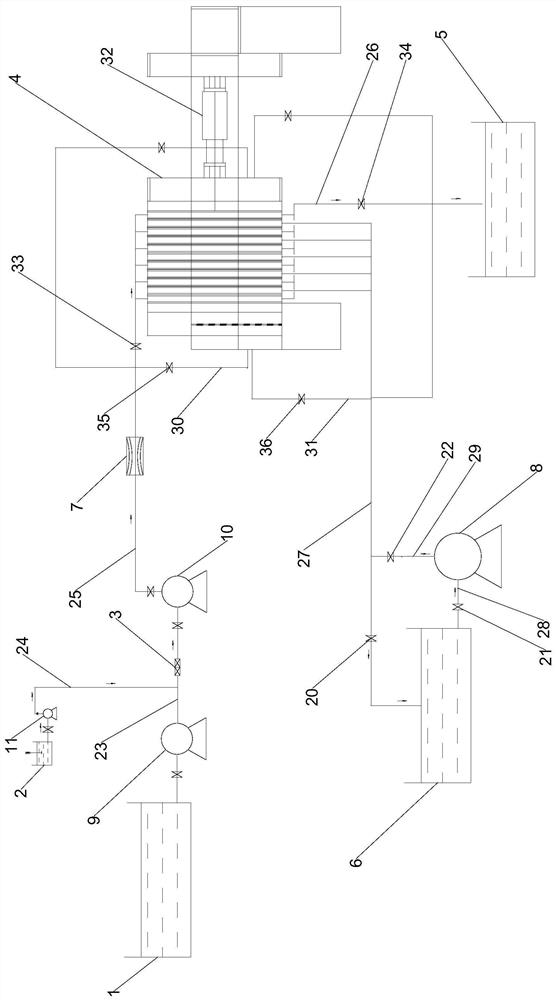

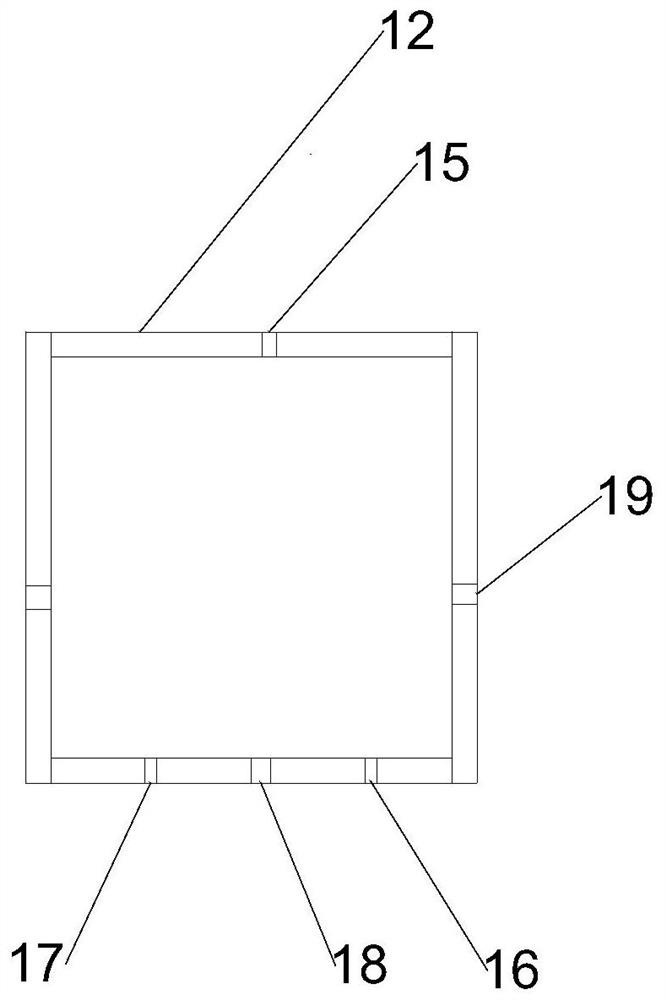

[0051] Such as Figure 1-Figure 5 As shown, a low turbidity precision sewage filtration system, including

[0052] Sewage pool 1, for storing sewage;

[0053] Dosing box 2, used to store flocculants for sewage treatment;

[0054] The dosing mixer 3 is used to receive the sewage from the sewage tank 1 and the flocculant from the dosing tank 2, and mix the sewage and the flocculant. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

| detection limit | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com