Polytetrafluoroethylene waterproof gas-permeable membrane and preparation method thereof

A technology of polytetrafluoroethylene, waterproof and breathable membrane, applied in the direction of coating, etc., can solve the problems of incomplete sealing of gas sensors, damage, low strength of waterproof and breathable membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

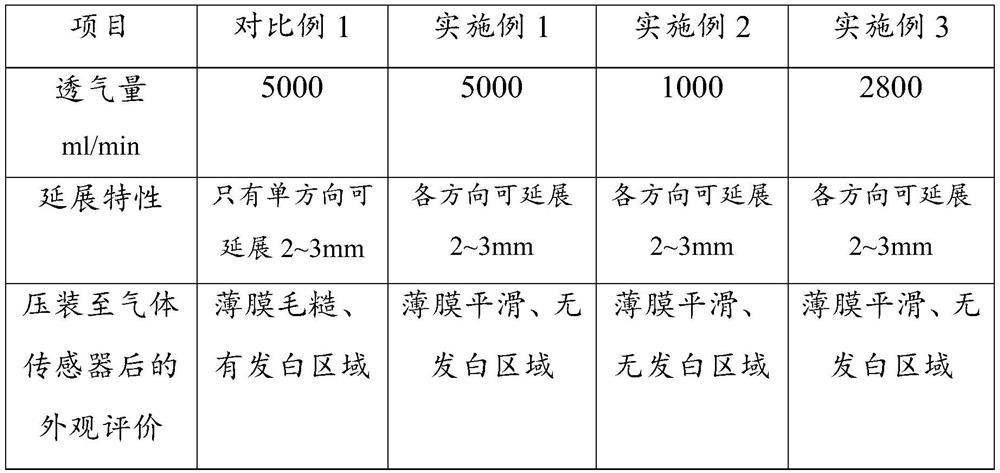

Embodiment 1

[0027] Take 40 parts by weight of polytetrafluoroethylene emulsion substrate, add 10 parts by weight of pore-forming agent filler zinc oxide, add 30 parts by weight of pore-forming agent filler alumina, add 10 parts by weight of cross-linking and dispersing aid anhydrous sodium sulfate , adding 10 parts by weight of cross-linking dispersion aid sodium chloride. After mixing and stirring evenly, heat to 380°C for molding and sintering to form a cylindrical billet. Then, the cylindrical blank is processed into a 100 diaphragm base material by a turning method. Then use acidic pore-forming agent remover with 10% concentration of hydrochloric acid to leach the pore-forming agent filler of the membrane substrate, and then use pure water to rinse the membrane substrate to remove the pore-forming agent leached from the membrane substrate. Then the film base material is dried under the condition of 60°C. Then use the high-temperature membrane hydrophobic treatment agent acetone boil...

Embodiment 2

[0029] Take 80 parts by weight of polytetrafluoroethylene emulsion substrate, add 5 parts by weight of pore-forming agent filler zinc oxide, add 5 parts by weight of pore-forming agent filler alumina, add 5 parts by weight of cross-linking and dispersing aid anhydrous sodium sulfate 1. Add 5 parts by weight of cross-linking and dispersing auxiliary agent sodium chloride. After mixing and stirring evenly, heat to 260°C for molding and sintering to form a cylindrical billet. Then, the cylindrical blank was processed into a diaphragm base material with a thickness of 100 um by a turning method. Then use acidic pore-forming agent remover with 10% concentration of hydrochloric acid to leach the pore-forming agent filler of the membrane substrate, and then use pure water to rinse the membrane substrate to remove the pore-forming agent leached from the membrane substrate. Then the film base material is dried under the condition of 100°C. Then use the high-temperature membrane hydro...

Embodiment 3

[0031] Take 65 parts by weight of polytetrafluoroethylene emulsion base material, add 15 parts by weight of pore-forming agent filler zinc oxide, add 5 parts by weight of pore-forming agent filler alumina, add 10 parts by weight of cross-linking and dispersing aid anhydrous sodium sulfate 1. Add 5 parts by weight of cross-linking and dispersing auxiliary agent sodium chloride. After mixing and stirring evenly, heat to 300°C for molding and sintering to form a cylindrical billet. Then, the cylindrical blank was processed into a diaphragm base material with a thickness of 100 um by a turning method. Then use acidic pore-forming agent remover with 10% concentration of hydrochloric acid to leach the pore-forming agent filler of the membrane substrate, and then use pure water to rinse the membrane substrate to remove the pore-forming agent leached from the membrane substrate. Then the film base material is dried under the condition of 90°C. Then use the high-temperature membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com