Layered Co3O4 lithium ion battery negative electrode material and preparation method thereof

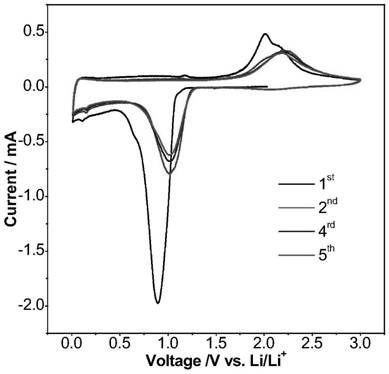

A technology of lithium-ion batteries and negative electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low specific capacity of negative electrode materials, and achieve the effects of increasing transmission speed, increasing specific capacity, and enhancing magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

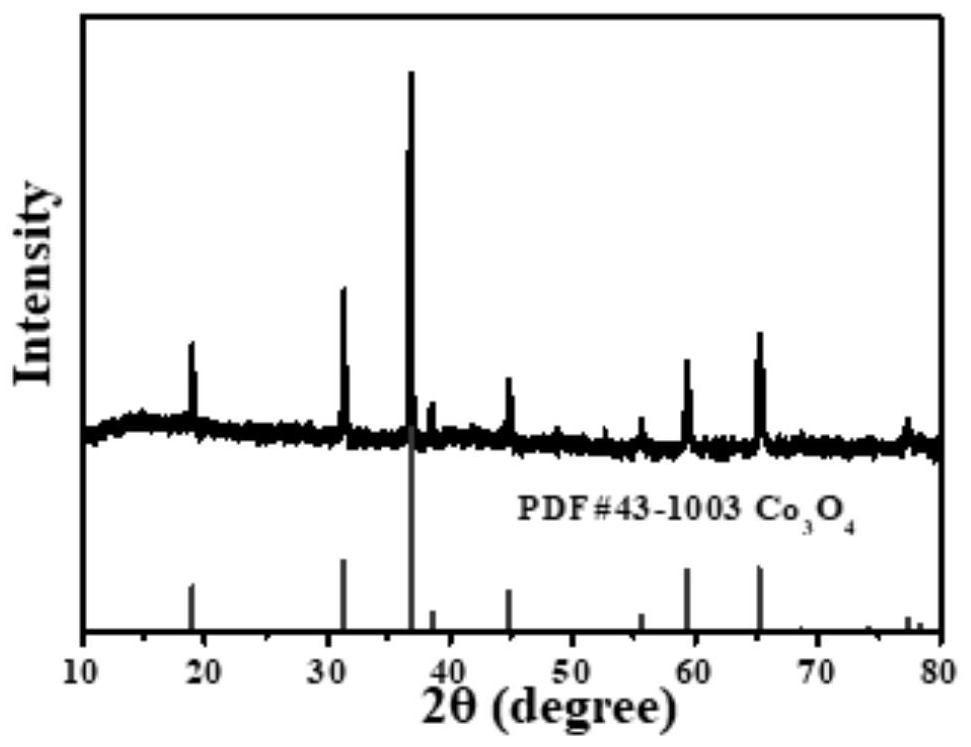

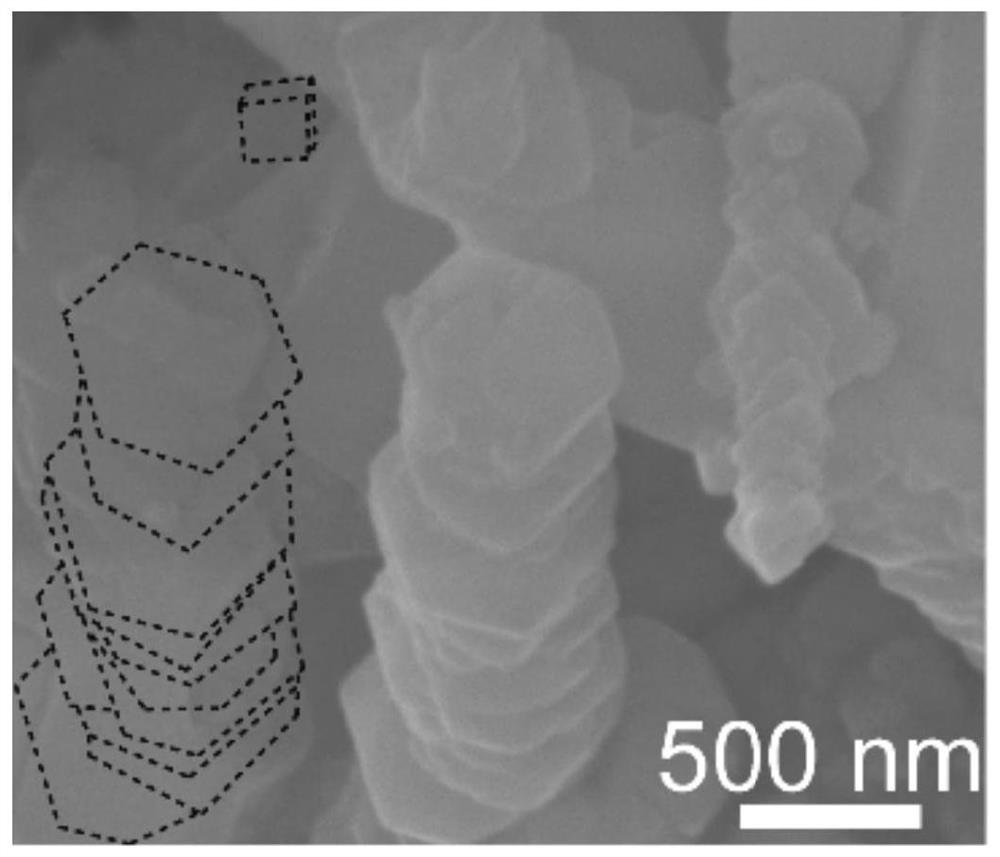

[0032] A layered Co 3 o 4 Lithium-ion battery anode materials, including layered Co that can be used to prepare lithium-ion battery anode materials 3 o 4 , layered Co 3 o 4 It is a layered stack structure, layered Co 3 o 4 After stacking, a rod-shaped profile is formed, which is specifically prepared by the following steps:

[0033] S1, Co(NO 3 ) 2 ·6H 2 O and CoCl3 ·6H 2 O is mixed in a molar ratio of 1:1, and then added to 60mL of the shape-directing agent to prepare a precursor solution. At this time, the concentration of the precursor solution is 0.33mol / L, wherein the shape-directing agent is Containing the mixed solution of ethylene glycol and 8.3wt% ammoniacal liquor;

[0034] S2. Stir the precursor solution for 1 hour, then transfer the fully reacted precursor solution to the reactor for solvothermal reaction, control the reaction temperature to 220°C, and control the heating time to 18 hours. The reactor was allowed to stand and cooled to room temperature ...

Embodiment 2

[0038] A layered Co 3 o 4 Lithium-ion battery anode materials, including layered Co that can be used to prepare lithium-ion battery anode materials 3 o 4 , layered Co 3 o 4 It is a layered stack structure, layered Co 3 o 4 After stacking, a rod-shaped profile is formed, which is specifically prepared by the following steps:

[0039] S1, Co(NO 3 ) 2 ·6H 2 O and CoCl 3 ·6H 2 O is mixed in a molar ratio of 1:1, and then added to 60mL of the shape-directing agent to prepare a precursor solution. At this time, the concentration of the precursor solution is 0.6mol / L, wherein the shape-directing agent is Containing the mixed solution of ethylene glycol and 10wt% ammoniacal liquor;

[0040] S2. Stir the precursor solution for 2 hours, then transfer the fully reacted precursor solution to the reactor for solvothermal reaction, control the reaction temperature to 180°C, and control the heating time to 24 hours. The reactor was allowed to stand and cooled to room temperature...

Embodiment 3

[0044] A layered Co 3 o 4 Lithium-ion battery anode materials, including layered Co that can be used to prepare lithium-ion battery anode materials 3 o 4 , layered Co 3 o 4 It is a layered stack structure, layered Co 3 o 4 After stacking, a rod-shaped profile is formed, which is specifically prepared by the following steps:

[0045] S1, Co(NO 3 ) 2 ·6H 2 O and CoCl 3 ·6H 2 O is mixed in a molar ratio of 1:1, and then added to 60mL of the shape-directing agent to prepare a precursor solution. At this time, the concentration of the precursor solution is 0.2mol / L, wherein the shape-directing agent is Contain the mixed solution of ethylene glycol and 5wt% ammoniacal liquor;

[0046] S2. Stir the precursor solution for 2 hours, then transfer the fully reacted precursor solution to the reactor for solvothermal reaction, control the reaction temperature to 250°C, and control the heating time to 12 hours. The reactor was allowed to stand and cooled to room temperature to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com