Production process of enhanced porcelain tile

A production process and enhanced technology, applied in the field of production technology of enhanced ceramic tiles, can solve the problems of inability to meet normal use requirements, general thermal insulation effect of ceramic tiles, and reduced service life of ceramic tiles, etc. Improve the effect of thermal insulation and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

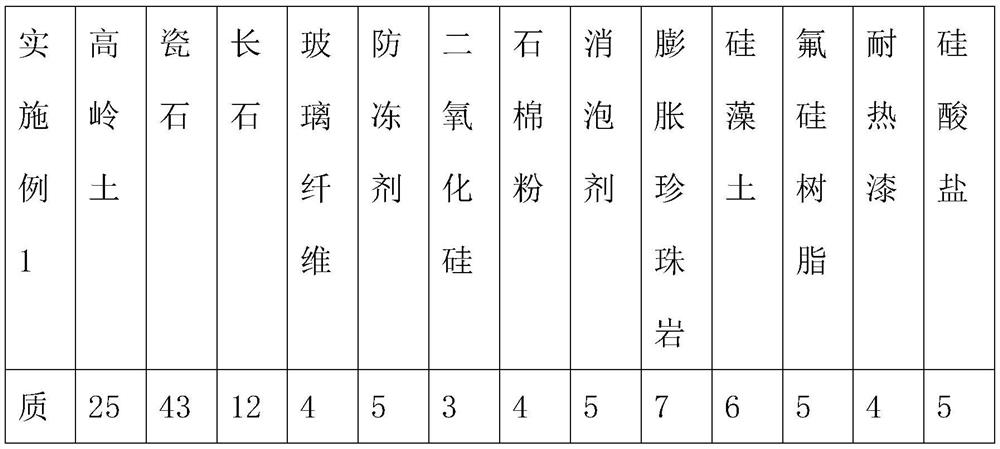

Embodiment 1

[0022] A production process for enhanced porcelain tiles, the porcelain tiles are composed of the following raw materials: 25 parts by mass of kaolin, 43 parts by mass of china clay, 12 parts by mass of feldspar, 4 parts by mass of glass fiber, 5 parts by mass of antifreeze, silicon dioxide 3 parts by mass, 4 parts by mass of asbestos powder, 5 parts by mass of defoamer, 7 parts by mass of expanded perlite, 6 parts by mass of diatomaceous earth, 5 parts by mass of fluorosilicone resin, 4 parts by mass of heat-resistant paint, 5 parts by mass of silicate share.

[0023] The production technique in the present embodiment comprises the following steps:

[0024] Step 1: Collect kaolin, china clay, and feldspar from the mining area or raw material origin, and then put a certain proportion of feldspar into the coarse aggregate crusher to crush the feldspar, and then crush the feldspar into powder, then use The filter screen removes impurities and filters the powder, and then remove...

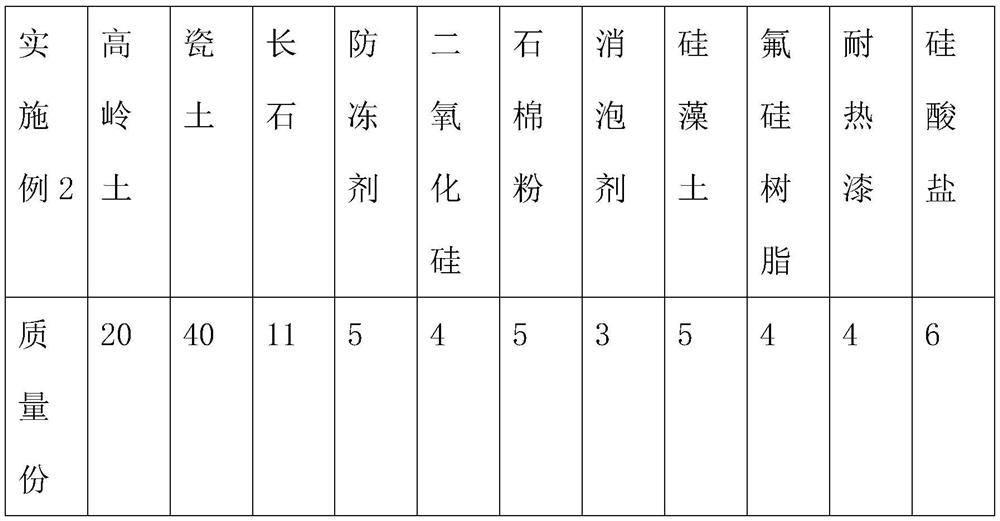

Embodiment 2

[0032] A production process for enhanced porcelain tiles, the porcelain tiles are composed of the following raw materials: 20 parts by mass of kaolin, 40 parts by mass of china clay, 11 parts by mass of feldspar, 5 parts by mass of antifreeze, 4 parts by mass of silicon dioxide, and asbestos powder 5 parts by mass, 3 parts by mass of defoamer, 5 parts by mass of diatomaceous earth, 4 parts by mass of fluorosilicone resin, 4 parts by mass of heat-resistant varnish, and 6 parts by mass of silicate.

[0033] The production technique in the present embodiment comprises the following steps:

[0034] Collect kaolin, china clay, and feldspar from the mining area or raw material origin, and then put a certain proportion of feldspar into the coarse aggregate crusher to crush the feldspar, and then crush the feldspar into powder, and then use a filter to crush the feldspar The powder is filtered for impurity removal, and then the kaolin and china clay are removed for impurity removal, a...

Embodiment 3

[0041] A production process for enhanced porcelain tiles, the porcelain tiles are composed of the following raw materials: 22 parts by mass of kaolin, 40 parts by mass of china clay, 12 parts by mass of feldspar, 4 parts by mass of glass fiber, 5 parts by mass of antifreeze, silicon dioxide 5 parts by mass, 4 parts by mass of asbestos powder, 8 parts by mass of expanded perlite, 7 parts by mass of diatomaceous earth, 5 parts by mass of fluorosilicone resin, 4 parts by mass of heat-resistant paint, and 6 parts by mass of silicate.

[0042] The production technique in the present embodiment comprises the following steps:

[0043] Step 1: Collect kaolin, china clay, and feldspar from the mining area or raw material origin, and then put a certain proportion of feldspar into the coarse aggregate crusher to crush the feldspar, and then crush the feldspar into powder, and then use The filter screen removes impurities and filters the powder, and then removes kaolin and china clay, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com