Large-mode-field photonic crystal fiber amplifier and preparation method thereof

A photonic crystal fiber, large mode field technology, applied in lasers, phonon exciters, laser parts and other directions, can solve the problem of no photonic crystal fiber amplifier structure preparation process, etc., to improve the flexibility of use, expand the scope of use, The effect of improving the quality of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

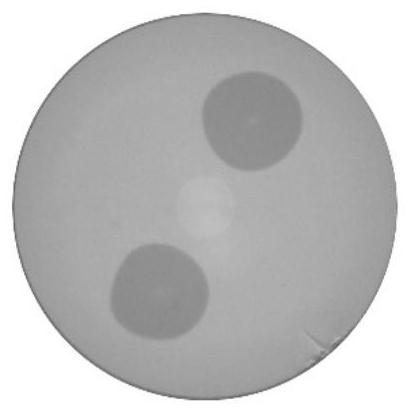

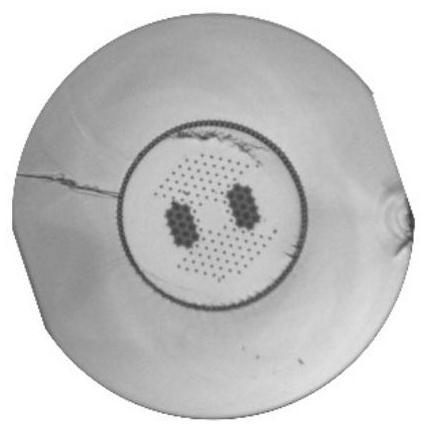

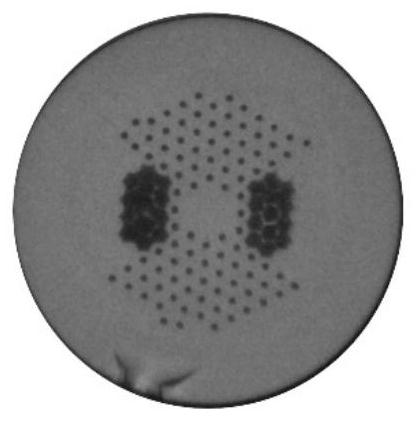

Image

Examples

preparation example Construction

[0042] The preparation method of the above-mentioned large mode field photonic crystal fiber amplifier comprises the following steps:

[0043] 1) According to the mode field size of the cladding beam combiner, the pure silica photonic crystal fiber is tapered to obtain the cladding combining fiber, and the mode field size of the cladding combining fiber after tapering is the same as The mode field size of the cladding beam combiner is matched, and the "adiabatic" transmission condition of the optical fiber fundamental mode is satisfied when tapered;

[0044] 2) Use commercial VytranLDC401 to process the end faces of all optical fibers to ensure that the cut end faces are clean and free of cracks and debris. The cladding fiber is reduced by 30%-50%;

[0045] 3) Clean the end faces of all optical fibers after cutting with ultrasonic alcohol mixture, and 2 Short-term, low-power heating on the fusion splicer;

[0046] 4) The fusion splicing of the mode-matched photonic crystal ...

Embodiment

[0052] The specific preparation process of the large mode field photonic crystal fiber amplifier of the present invention is as follows:

[0053] 1) On the Vytran3000 fusion splicer, select the tapering program with an outer diameter of 450 microns, and use a mode-matched photonic crystal fiber with an outer diameter of 450 microns for power correction, and reduce the heating power by half on the basis of the corrected power for tapering: put the outer The diameter is 450 microns, the cladding is 200 microns pure silica photonic crystal fiber is drawn to the outer diameter of 280 microns, the cladding is 125 microns, the length of the cone is 7mm, and the waist is 10mm;

[0054] 2) Use the VytranLDC400 cleaver to select a cutting program of 250 microns to cut the photonic crystal fiber, or use the CT105 cleaver to cut the bundled cladding fiber and reduce the cutting tension by 25%. The thimble of the cleaver rotates until it just touches the The state of the optical fiber is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com