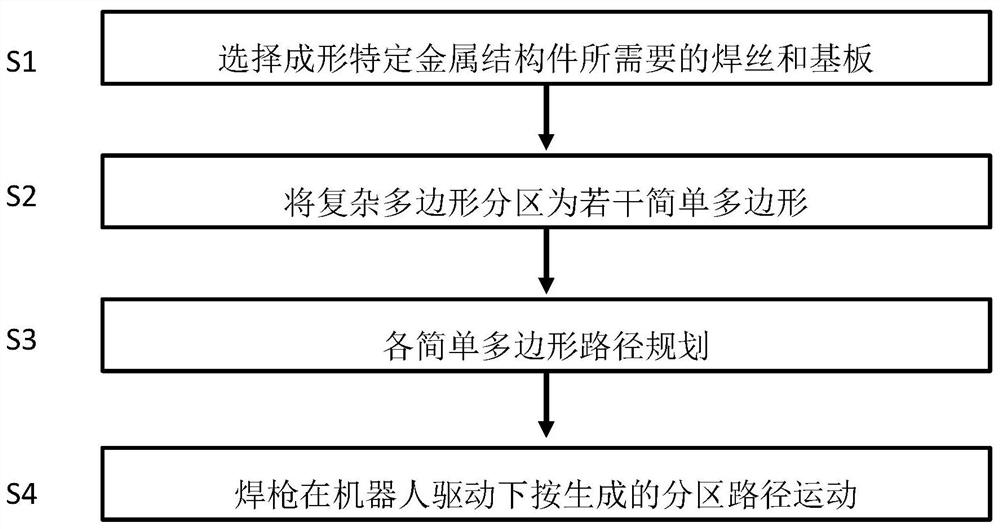

Arc additive manufacturing method for partition printing and filling of reinforcing rib metal structural part

A technology of metal structural parts and additive manufacturing, which is applied in the field of additive manufacturing, can solve the problems of large differences in shape and size between ribs and substrates, uncontrollable filling path sequence, and concentrated heat input, so as to shorten the development cycle and improve 3D printing speed, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

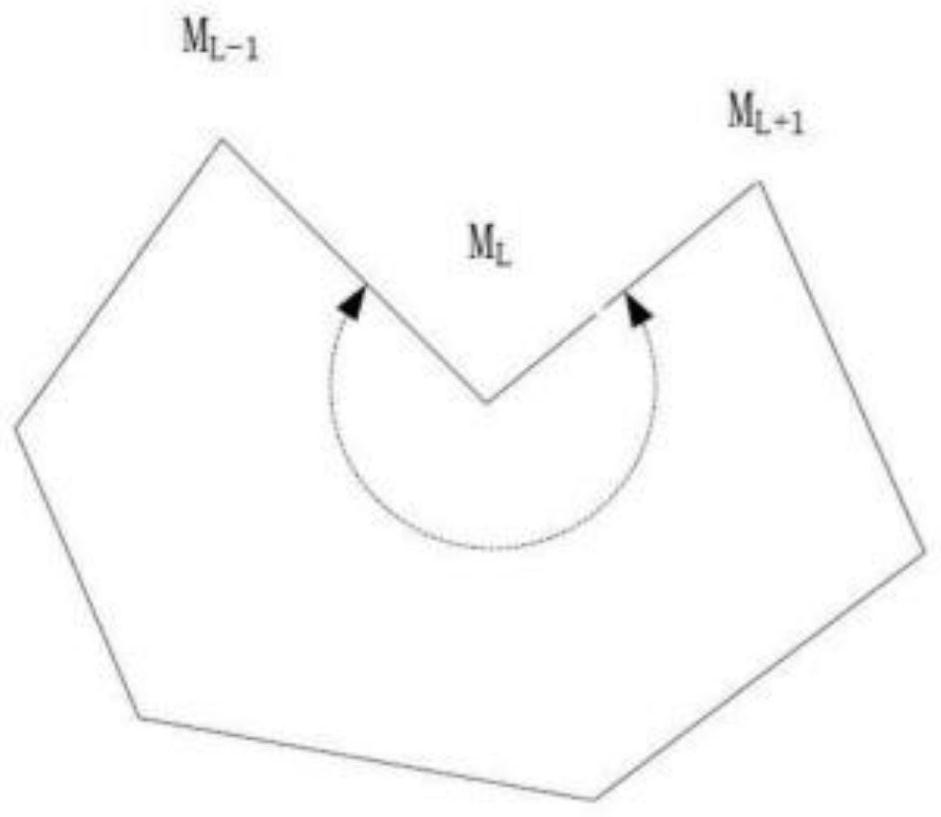

Method used

Image

Examples

Embodiment 1

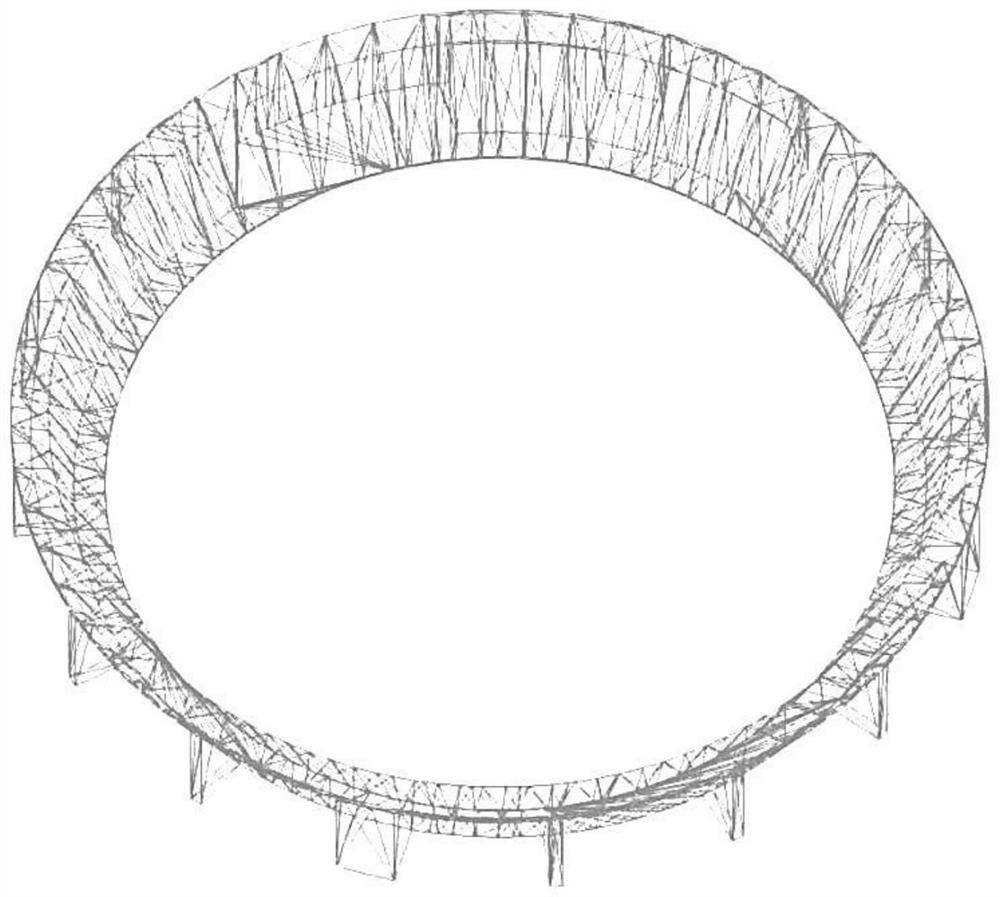

[0098] Example 1: Additive manufacturing of 4043 aluminum alloy reinforced rib metal structural parts filled with arc

[0099] like Image 6 As shown, the height of the aluminum alloy structural part is 200mm, and the number of layered slices is 134 layers, so the weld height of each layer is 1.5mm. It adopts a metal structure with reinforcing ribs described in the present invention to be manufactured by subarea filling arc additive. Specifically:

[0100] Print the selected 6061 aluminum alloy substrate with a thickness of 20mm. The welding wire used is 4043 aluminum alloy wire with a diameter of 1.2mm. First, calculate the heat input through the optimal temperature required for workpiece forming, so as to obtain a set of suitable forming process parameters: select The welding process is CMT+P, the welding current is 110A, the wire feeding speed is 5.8m / min, the welding speed is 10mm / s, the shielding gas is Arcal1 (99.9995% Ar), and the gas flow rate is 18L / min. Due to the ...

Embodiment 2

[0101] Example 2: Additive manufacturing of 316L stainless steel ribbed metal structural parts filled with arc

[0102] like Figure 7 As shown, the height of the stainless steel structural part is 200mm, and the number of layers of sliced slices is 112, so the height of the weld of each layer is 1.8mm. It adopts a metal structure with reinforcing ribs described in the present invention to be manufactured by subarea filling arc additive. Specifically:

[0103] Print the selected Q235 carbon steel substrate with a thickness of 20mm. The welding wire used is 316Lb stainless steel wire with a diameter of 1.2mm. First, calculate the heat input through the optimal temperature required for workpiece forming, so as to obtain a set of suitable forming process parameters: Selective welding The process is CMT+P, the welding current is 152A, the wire feeding speed is 4.8m / min, the welding speed is 10mm / s, and the shielding gas is Arcal12 (98%Ar+2%CO 2 ), the gas flow rate is 15L / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com