Salt-reducing fermentation method for high-salt liquid-state fermented soy sauce

A soy sauce and starter technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria used in food preparation, etc., can solve problems such as increased production costs, flavor, and decreased food safety of quality indicators, and achieve ester The effect of increasing the content of similar substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

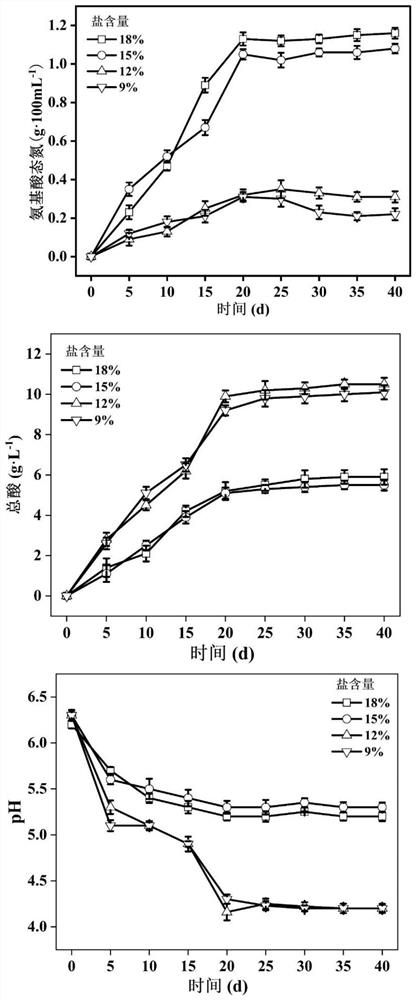

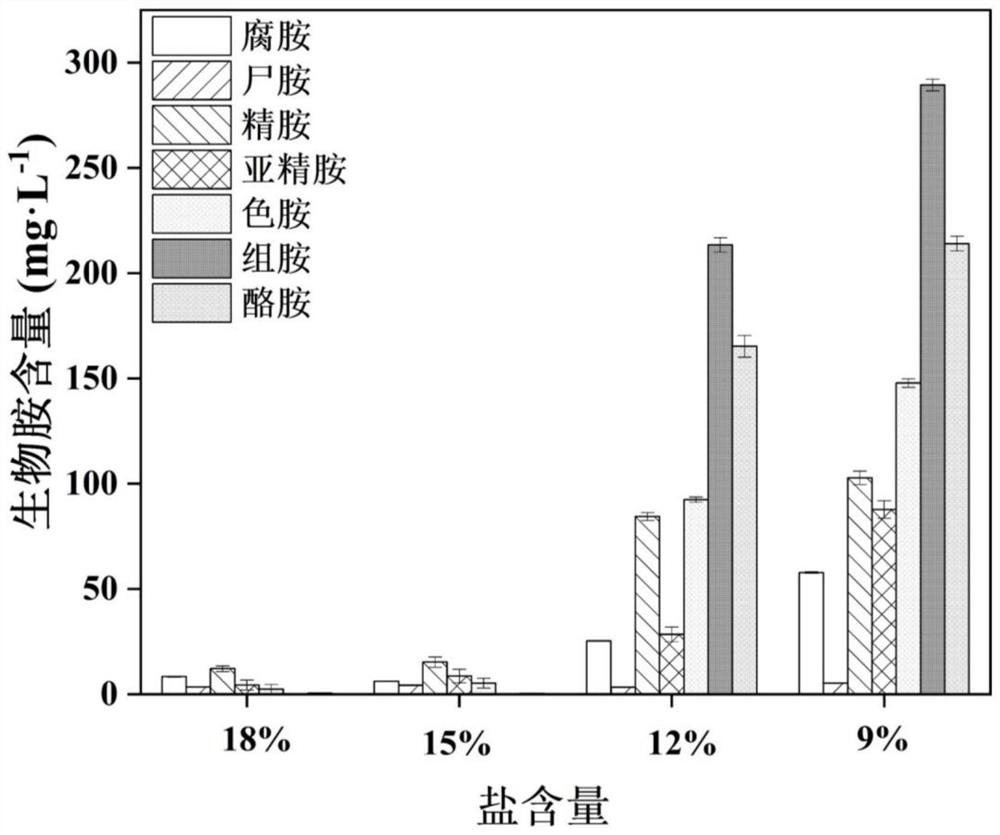

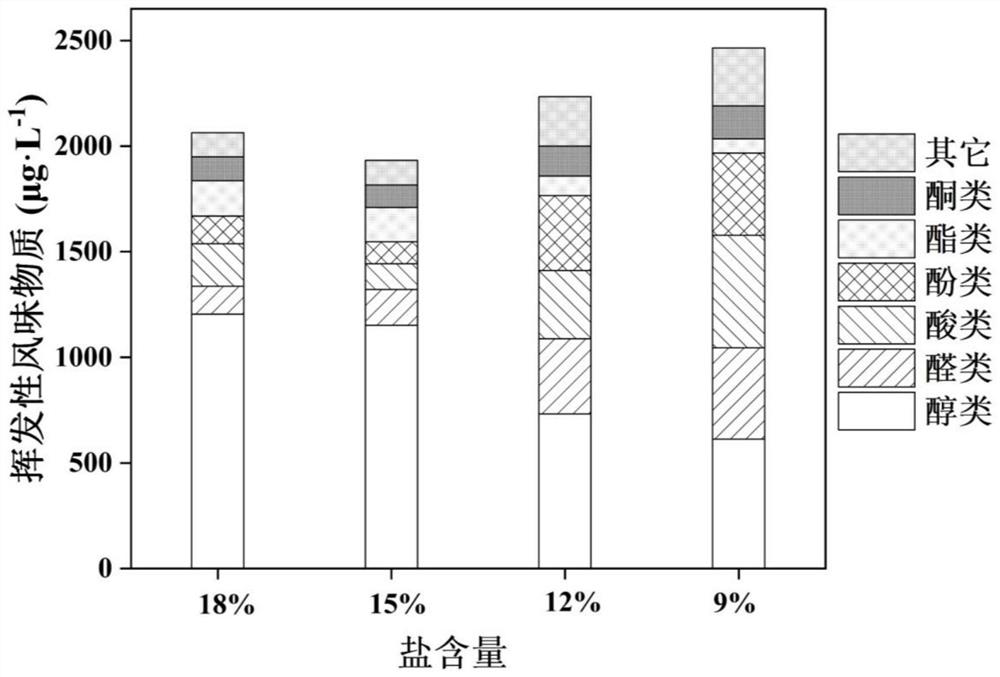

[0069] Embodiment 1: the salt reduction brewing of high-salt dilute soy sauce

[0070] (1) Music making:

[0071] The raw materials used for making koji include: defatted soybeans and wheat flour with a mass ratio of 6:4;

[0072] The specific steps are: mix the defatted soybean with 1.2 times of water evenly, sterilize at 121° C. for 15 minutes, and cool to room temperature. Then fully mix the defatted soybeans and wheat flour, then add soy sauce koji essence accounting for 1.5‰ of the total mass of the mixed raw materials, mix evenly and cultivate in a biochemical incubator at 28°C to 30°C, turn the koji at the right time, and make the koji for 40h~ After 48 hours, the surface of the koji material is covered with yellow-green hyphae, which is the finished koji.

[0073] (2) Fermentation: The finished koji prepared in step (1) is mixed with 200g L -1 The NaCl brine is mixed in a volume ratio of 1:(2~3). Put the evenly mixed moromi into 5L beakers, so that the final concen...

Embodiment 2

[0087]Embodiment 2: the screening identification and bacteriostatic spectrum that inhibit spoilage bacteria microorganism

[0088] (1) Screening of Weissella

[0089] With vancomycin (0.2g L -1 ) and natamycin (0.1g·L -1 ) MRS medium for isolation and screening of Weissella from moromi. Select the moromi samples of the 5th, 20th, and 35th day of fermentation, take 15g of moromi and put it in a beaker, add 135mL of sterile saline and add an appropriate amount of glass beads, 100r min- 1 Shake for 5 minutes, stand still at room temperature for 5 minutes, take 1 mL of bacterial suspension, apply gradient dilution to the solution containing vancomycin (0.2 g·L -1 ) and natamycin (0.1g·L -1 ) MRS medium, cultivated at 37°C for 1-3 days, picked a single colony and streaked to obtain a pure strain.

[0090] (2) Screening of Bacillus amyloliquefaciens

[0091] Take 5g of soy sauce and put it in 100mL beef extract-peptone liquid culture medium with glass beads and culture it stat...

Embodiment 3

[0107] Example 3: Synergistic fermentation of Weissella and Bacillus amyloliquefaciens to prepare salt-reduced soy sauce in a high-salt dilute state method

[0108] Cultivation of Weissella enteriferii: pick Weissella enterica JL-5 single bacterium colony obtained by screening in Example 2 and inoculate in the MRS medium, culture at 37° C. for 24 hours, press 1% (v / v) Proportionally transferred to fresh MRS medium, cultured at 37°C to OD 600 Reach 3.0.

[0109] Cultivation of Bacillus amyloliquefaciens: Pick a single colony of Bacillus amyloliquefaciens JDF-2 and inoculate it into liquid LB medium, culture it statically at 37°C for 24 hours, transfer it to fresh LB medium at a ratio of 1% (v / v), Cultured at 37°C to OD 600 Reach 3.0.

[0110] Cultivation of Zygomyces rouckeri: Pick a single colony of Zygomyces rouckeri and inoculate it into liquid YPD medium, 37°C, 220r min -1 Cultivate for 30 hours, inoculate into fresh YPD medium at a ratio of 1% (v / v), and cultivate to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com