Si-based double-sided double-junction AlGaAs solar cell and preparation method thereof

A solar cell, double-sided technology, applied in the field of solar photovoltaic, can solve the problems of high cost, complicated preparation process, unsuitable for large-scale industrial production, etc., to reduce the preparation cost, the preparation process is simple, and it is beneficial to the popularization and popularization of large-scale industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

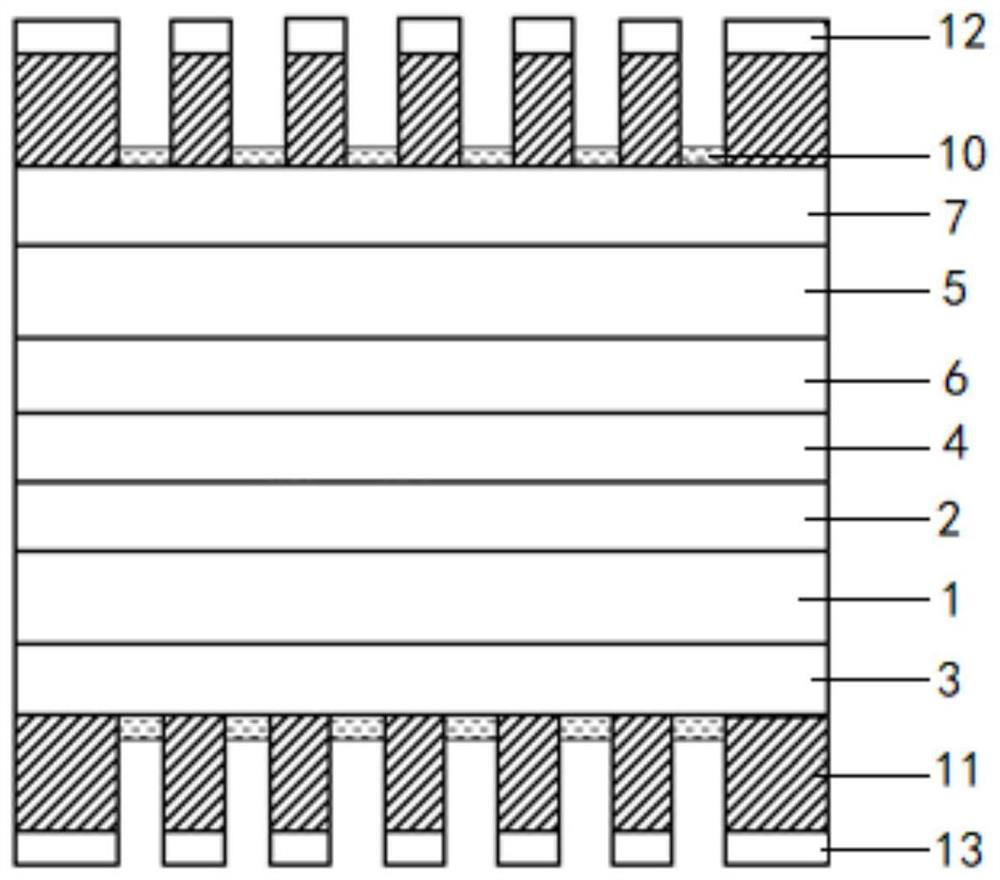

[0056] Such as figure 1 As shown, the present invention provides a Si-based double-sided double-junction AlGaAs solar cell, comprising: an N-type Si substrate 1 and an N-type AlGaAs functional layer 5;

[0057] The N-type Si substrate 1 is double-sided polished, and its upper and lower surfaces are doped to form P + - Si layer 2 and N + -Si layer 3; the upper and lower surfaces of the N-type AlGaAs functional layer 5 are respectively doped to form N + - AlGaAs layer 6 and P + - AlGaAs layer 7, N + -AlGaAs tunnel junction 4 is formed on the AlGaAs layer 6, and the AlGaAs tunnel junction 4 is bonded to the P + - on Si layer 2; P + -An anti-reflection film 10, an ohmic contact layer 11 and a front electrode 12 are formed on the AlGaAs layer 7, N + -An anti-reflection film 10 , an ohmic contact layer 11 and a rear electrode 13 are formed on the Si layer 3 .

[0058] Among them, the N-type AlGaAs functional layer 5, N + - AlGaAs layer 6, P + -AlGaAs layer 7 and AlGaAs tunn...

Embodiment 2

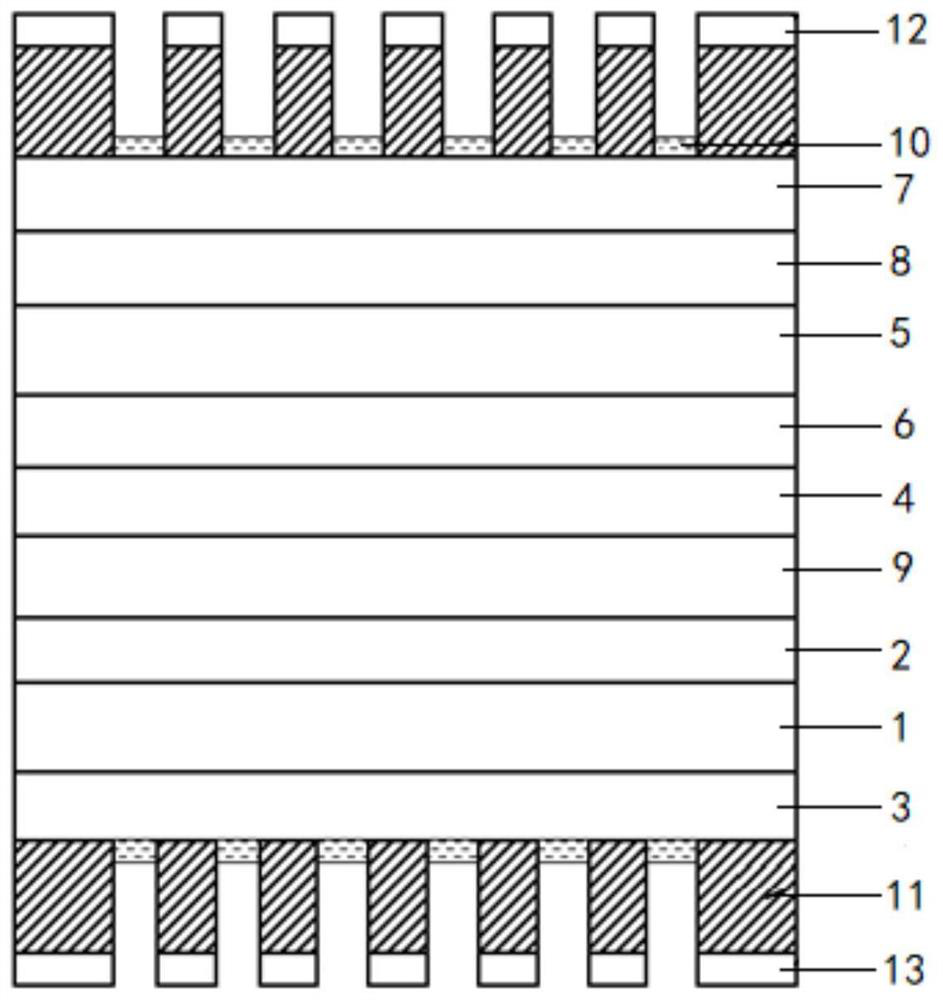

[0066] Such as figure 2 As shown, the present invention provides a Si-based double-sided double-junction AlGaAs solar cell, comprising: an N-type Si substrate 1, an N-type AlGaAs functional layer 5 and a P-type AlGaAs functional layer 8;

[0067] The N-type Si substrate 1 is double-sided polished, and its upper and lower surfaces are doped to form P + - Si layer 2 and N + - Si layer 3; P + -GaAs buffer layer 9, AlGaAs tunnel junction 4, N + -AlGaAs layer 6, N-type AlGaAs functional layer 5, P-type AlGaAs functional layer 8, P + - AlGaAs layer 7; P + -An anti-reflection film 10, an ohmic contact layer 11 and a front electrode 12 are formed on the AlGaAs layer 7, N + -An anti-reflection film 10 , an ohmic contact layer 11 and a rear electrode 13 are formed on the Si layer 3 .

[0068] Among them, the N-type AlGaAs functional layer 5, N + -AlGaAs layer 6 and AlGaAs tunnel junction 4 are Al 0.20 Ga 0.80 As,P + -AlGaAs layer 7 and P-type AlGaAs functional layer 8 are Al ...

Embodiment 3

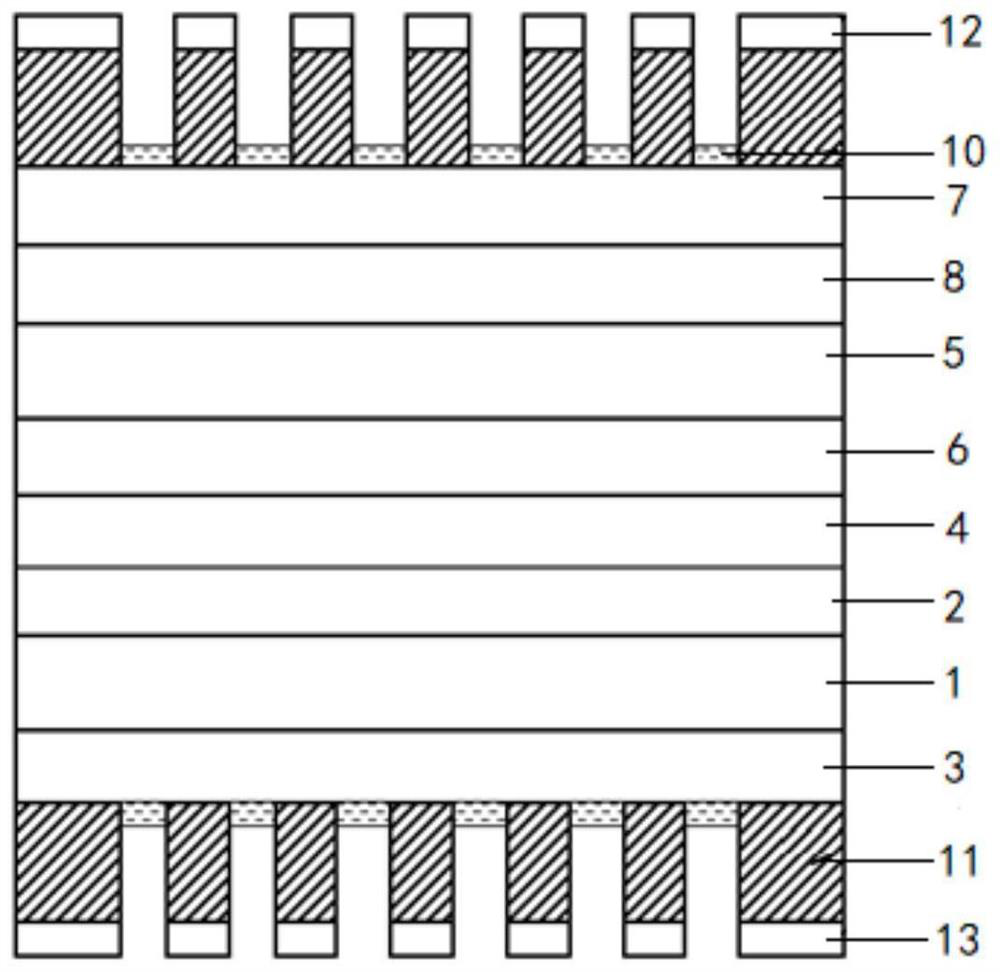

[0079] Such as image 3 As shown, the present invention provides a Si-based double-sided double-junction AlGaAs solar cell, comprising: an N-type Si substrate 1, an N-type AlGaAs functional layer 5 and a P-type AlGaAs functional layer 8;

[0080] The N-type Si substrate 1 is double-sided polished, and its upper and lower surfaces are doped to form P + - Si layer 2 and N + -Si layer 3; the lower surface of the N-type AlGaAs functional layer 5 is doped to form N + - AlGaAs layer 6 and AlGaAs tunnel junction 4, AlGaAs tunnel junction 4 bonded in P + - on the Si layer 2; the P-type AlGaAs functional layer 8 is bonded on the upper surface of the N-type AlGaAs functional layer 5, and the upper surface of the P-type AlGaAs functional layer 8 is doped to form P + - AlGaAs layer 7; P + -An anti-reflection film 10, an ohmic contact layer 11 and a front electrode 12 are formed on the AlGaAs layer 7, N + -An anti-reflection film 10 , an ohmic contact layer 11 and a rear electrode 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com