Sludge drying system and method based on carbon dioxide stepped series circulating high-temperature heat pump

A carbon dioxide and sludge drying technology, which is applied in chemical instruments and methods, heat pumps, sludge treatment, etc., can solve problems such as poor operating conditions, large air circulation, and slow drying speed, so as to improve efficiency, Improve system performance and avoid system performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

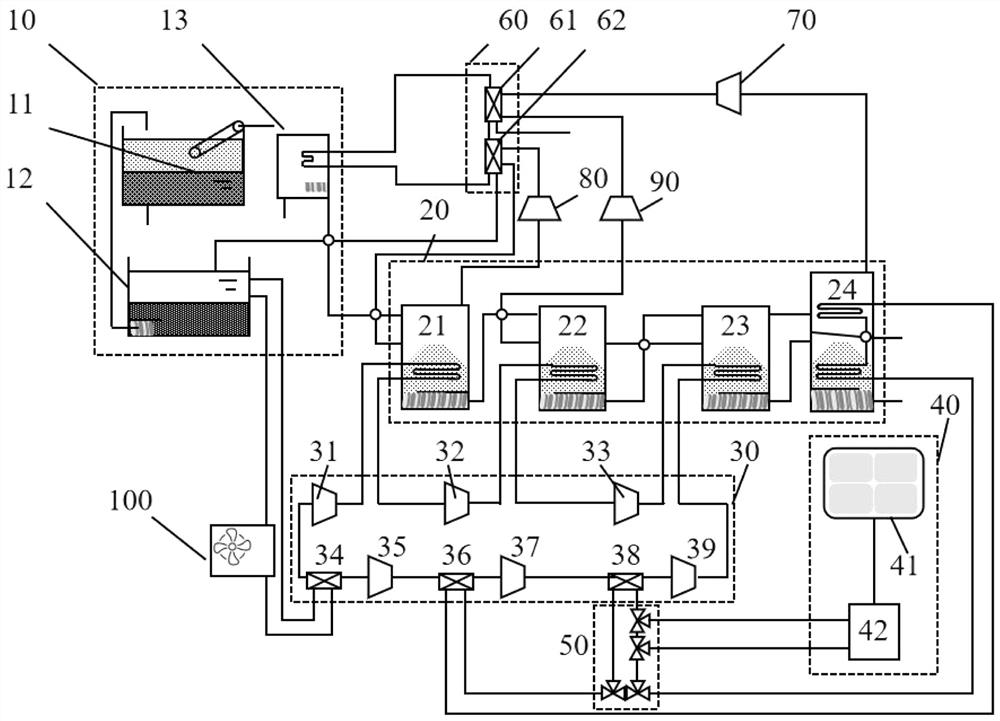

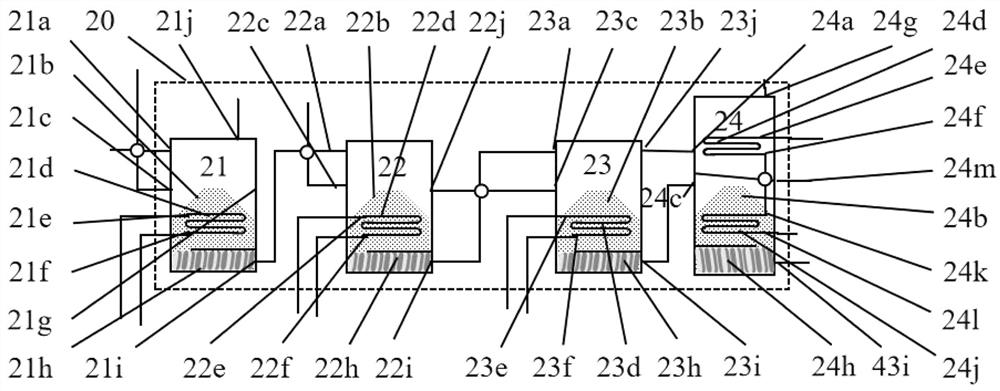

[0040] see Figure 1-6 , a sludge drying system based on a carbon dioxide cascaded series cycle high-temperature heat pump, which includes a sludge drying process system for drying sludge; the sludge drying process system is connected in series with a carbon dioxide cascade system for providing heat The circulation high-temperature heat pump system 30 is connected; the carbon dioxide cascaded series circulation high-temperature heat pump system 30 is connected with the clean power system 40 and the air quality energy circulation process system.

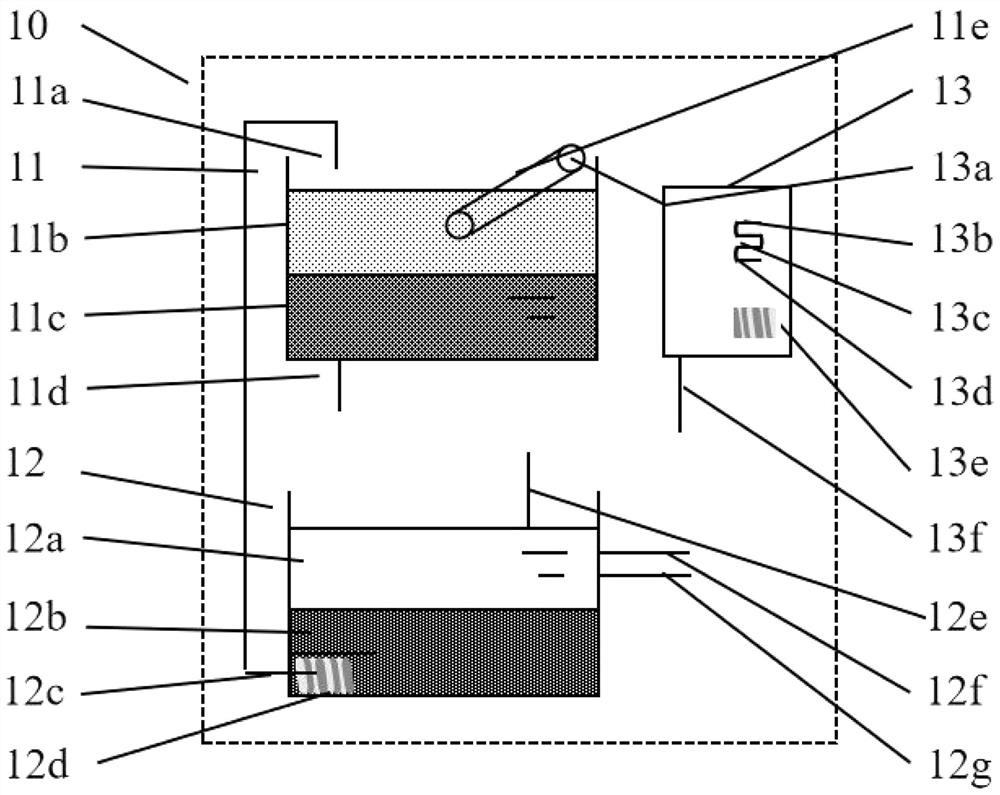

[0041] Further, the sludge drying system includes a drying pretreatment system 10 and an expansion type flash drying system 20; the drying pretreatment system 10 includes a sedimentation tank 12, and the sedimentation tank 12 is connected to a gravity concentration tank 11, The gravity concentration tank 11 is connected with the horizontal centrifugal drying device 13; the expansion type flash drying system 20 includes a low-temperatu...

Embodiment 2

[0047] see figure 2 , the sludge drying system consists of two parts: a drying pretreatment system 10 and a capacity-expanding flash drying system 20, wherein the drying pretreatment system 10 consists of a gravity concentration tank 11, a sedimentation tank 12, and a horizontal centrifugal drying system. The device 13 is composed of three main parts. During the implementation process, the raw sludge is separated from the gravity concentration tank 11 successively in the sedimentation tank 12, and the centrifugal separation and preheating process of the horizontal centrifugal drying device 13 treats the sludge to 80% water content. The left and right temperature is about 40°C. The specific implementation method is: the raw sludge and sewage mixture in the sedimentation tank 12 are separated by standing to form the upper sewage layer 12a and the saturated sludge layer 12b, and the circulating waterway inlet and outlet 12f of the upper sewage layer 12a of the sedimentation tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com