Method for recovering side chain in ganciclovir condensation compound mother liquor

A technology of ganciclovir condensate and recovery method, applied in the field of industrial waste liquid treatment and recovery, can solve problems such as increasing raw material cost, environmental impact, waste of resources, etc., achieve good social benefits, reduce raw material cost, and realize resource recycling The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

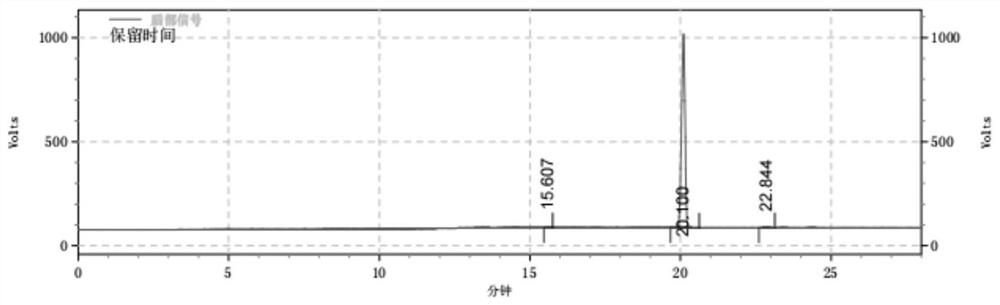

Embodiment 1

[0039]Put 100kg of diacetylguanine, 30kg of ganciclovir condensate isomers, 100kg of ganciclovir side chains and 300kg of DMF into the reaction kettle, add 1kg of p-toluenesulfonic acid, and keep warm at 120-130°C for 45h. After the reaction was completed, the solvent was concentrated under reduced pressure, 800 kg of methanol was added to dissolve the residue, the solution was cooled to 25-30° C., and stirred for 3 hours to crystallize. Centrifuge, concentrate the centrifuged mother liquor under reduced pressure, dissolve the concentrated residue with a mixed solvent composed of 100kg methanol and 600kg toluene, and then cool to 5-10°C for crystallization for 2h. After centrifugation, the filtrate is pumped into a transfer kettle, and 100kg of water and 200kg of methanol are added to the transfer kettle, stirred for 45 minutes, and centrifuged. The filter cake is solid waste, the filtrate is transferred to the extraction kettle, stirred for 30 minutes, left to stand for 15 mi...

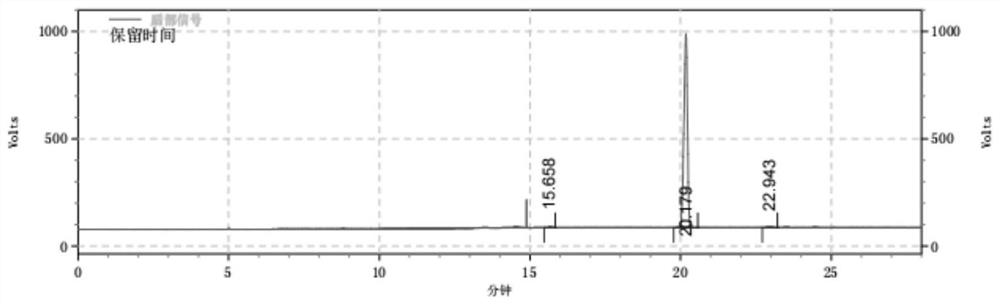

Embodiment 2

[0043] Put 100kg of diacetylguanine, 30kg of ganciclovir condensate isomers, 100kg of ganciclovir side chains and 300kg of DMF into the reaction kettle, add 1kg of p-toluenesulfonic acid, and keep warm at 120-130°C for 45h. After the reaction was completed, the solvent was concentrated under reduced pressure, 800 kg of methanol was added to dissolve the residue, the solution was cooled to 25-30° C., and stirred for 3 hours to crystallize. Centrifuge, concentrate the centrifuged mother liquor under reduced pressure, dissolve the concentrated residue with a mixed solvent composed of 100kg methanol and 600kg toluene, and then cool to 5-10°C for crystallization for 2h. After centrifugation, the filtrate is pumped into a transfer kettle, and 100kg of water and 200kg of methanol are added to the transfer kettle, stirred for 45 minutes, and centrifuged. The filter cake is solid waste, the filtrate is transferred to the extraction kettle, stirred for 30 minutes, left to stand for 15 m...

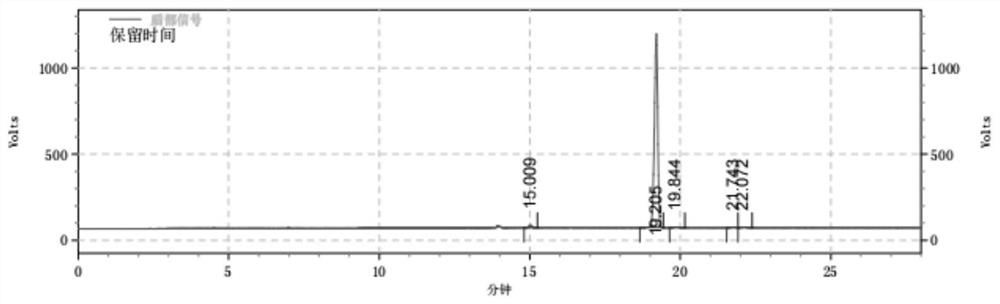

Embodiment 3

[0047] Put 100kg of diacetylguanine, 30kg of ganciclovir condensate isomers, 100kg of ganciclovir side chains and 300kg of DMF into the reaction kettle, add 1kg of p-toluenesulfonic acid, and keep warm at 120-130°C for 45h. After the reaction was completed, the solvent was concentrated under reduced pressure, 800 kg of methanol was added to dissolve the residue, the solution was cooled to 25-30° C., and stirred for 3 hours to crystallize. Centrifuge, concentrate the centrifuged mother liquor under reduced pressure, dissolve the concentrated residue with a mixed solvent composed of 100kg methanol and 600kg toluene, and then cool to 5-10°C for crystallization for 2h. After centrifugation, the filtrate is pumped into a transfer kettle, and 100kg of water and 200kg of methanol are added to the transfer kettle, stirred for 45 minutes, and centrifuged. The filter cake is solid waste, the filtrate is transferred to the extraction kettle, stirred for 30 minutes, left to stand for 15 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com