Organosilicon copolymer, preparation method and application thereof, polyurethane foam stabilizer and polyurethane foam

A polyurethane foam and silicone technology, applied in the field of polyurethane foam stabilizer and polyurethane foam, can solve problems such as environmental pollution, physical damage to production personnel, and reduce the performance of foam stabilizer, so as to avoid side reactions, avoid personal injury and harm the environment. pollution and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the second aspect, an embodiment of the present invention provides a method for preparing a silicone copolymer, comprising:

[0039] S1, synthesizing polyether methacrylate;

[0040] Reaction of methacrylic acid and polyether butyl glycidyl ether to form polyether methacrylate; specifically, mixing the methacrylic acid, the polyether butyl glycidyl ether, a polymerization inhibitor and a first catalyst Reaction; further, the polyether butyl glycidyl ether and the polymerization inhibitor are mixed, then the temperature is raised under a protective gas atmosphere, and then the temperature is maintained, and then the methacrylic acid and the first catalyst are added to carry out Reaction; The embodiment of the present invention does not use allyl alcohol as the polyether polyol of starter, thus has avoided the side reaction that brings because of allyl alcohol isomerization, and has also avoided because of using allyl alcohol to the personnel injury and pollution of t...

Embodiment 1

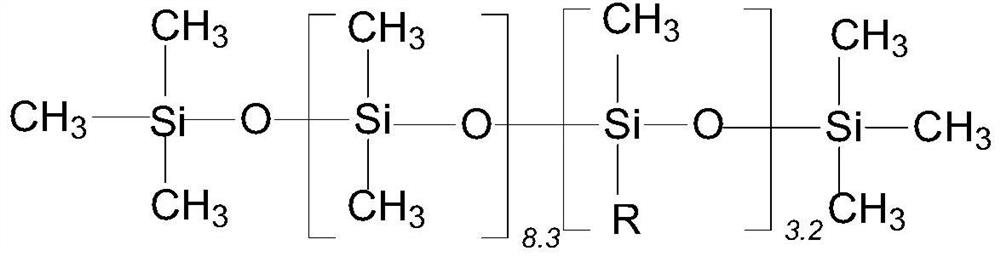

[0053] The embodiment of the present invention provides a silicone copolymer whose structural formula is characterized as follows: Among them, the structural formula of R is: -CH 2 CH(CH 3 ) COOCH 2 CHOHCH 2 O(CH 2 CH 2 O) 6 C 4 h 9 .

[0054] An embodiment of the present invention provides a method for preparing a silicone copolymer, comprising:

[0055] (1) React 119.5g of octamethylcyclotetrasiloxane, 42.22g of high hydrogen-containing silicone oil and 38.28g of hexamethyldisiloxane under the action of concentrated sulfuric acid at 30°C for 7 hours to obtain hydrogen-containing silicone oil.

[0056] (2) Weigh 472.86g polyether butyl glycidyl ether and 0.28g polymerization inhibitor tetramethylpiperidine nitrogen oxide and place it in the reactor, stir to make the polymerization inhibitor dissolve evenly, and under nitrogen protection, slowly heat up to 110 ~115°C, after the temperature is stabilized, add dropwise a mixture of 86.02g methacrylic acid and 0.55g ca...

Embodiment 2

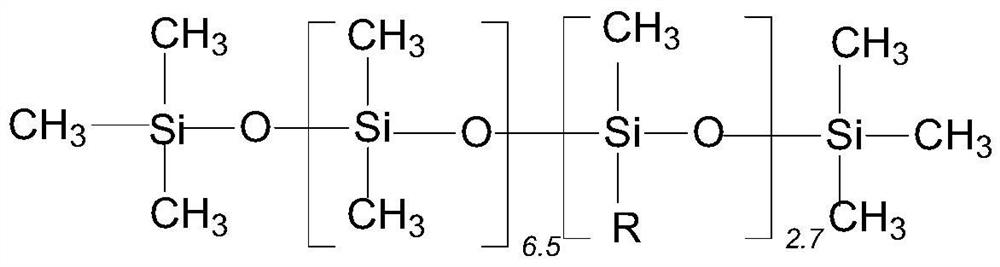

[0059] The embodiment of the present invention provides a silicone copolymer whose structural formula is characterized as follows:

[0060] Among them, the structural formula of R is: -CH 2 CH(CH 3 ) COOCH 2 CHOHCH 2 O(CH 2 CH 2 O) 7 (CH 2 CH(CH3)O) 1 C 4 h 9 .

[0061] An embodiment of the present invention provides a method for preparing a silicone copolymer, comprising:

[0062] (1) React 106.34g of octamethylcyclotetrasiloxane, 56.14g of high hydrogen-containing silicone oil and 37.52g of hexamethyldisiloxane under the action of concentrated sulfuric acid at 30°C for 7 hours to obtain hydrogen-containing silicone oil.

[0063] (2) Take by weighing 452.85g polyether butyl glycidyl ether and 0.15g polymerization inhibitor tetramethylpiperidine nitrogen oxide and 0.10g p-hydroxyanisole and place in the reactor, stir to make the polymerization inhibitor dissolve evenly, Under the protection of nitrogen, slowly raise the temperature to 110-115°C. After the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com