Method for efficiently producing rhizopus oryzae lipase by using aspergillus oryzae

A technology of Rhizomucor oryzae and Aspergillus oryzae, which is applied in the field of high-efficiency production of Rhizomucor oryzae lipase by Aspergillus oryzae, can solve the problems of agglomeration, reducing production efficiency, affecting mass transfer and mixing of fermented liquid, and achieving yield and Improvement of enzyme activity and effect of increasing effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

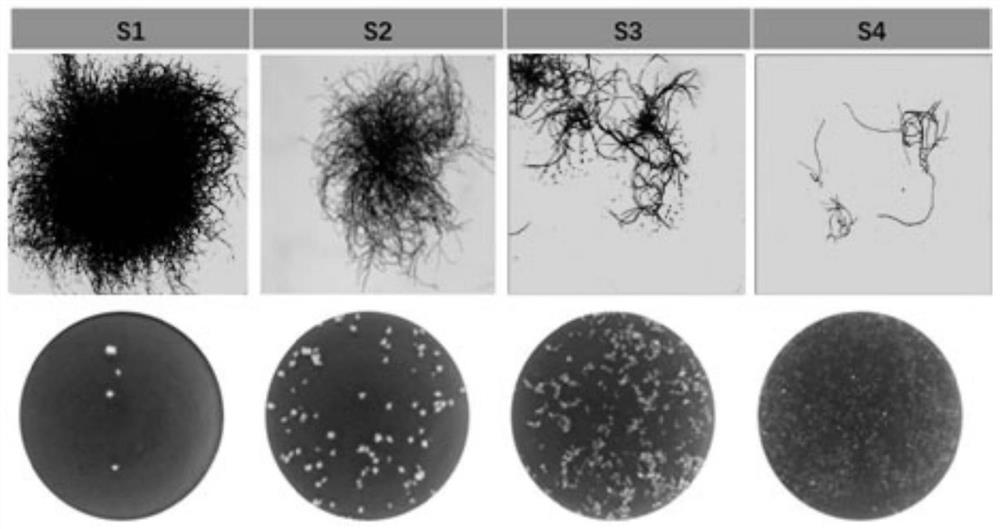

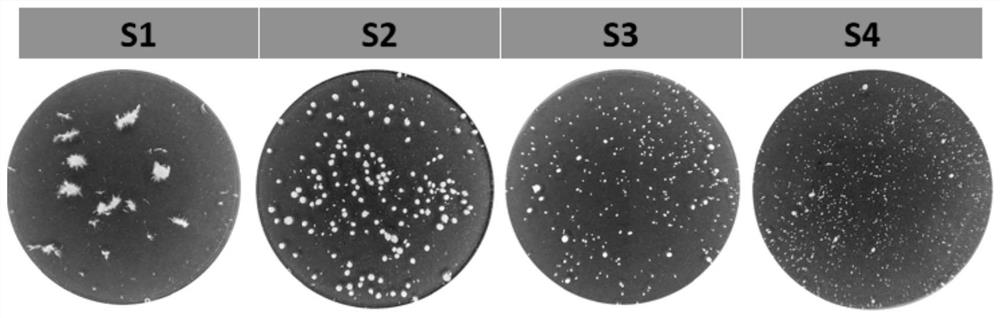

[0068] The present embodiment provides a method for efficient production of Rhizomucor miehei lipase by Aspergillus oryzae, comprising steps:

[0069] Seed culture: inoculate the spore suspension of Aspergillus oryzae in the seed medium according to the inoculation amount of 0.6%, and cultivate it for 28 hours at a temperature of 28°C and a rotation speed of 150rpm to obtain a seed liquid; wherein, the spore suspension The concentration of spores is 2×10 5 a / mL;

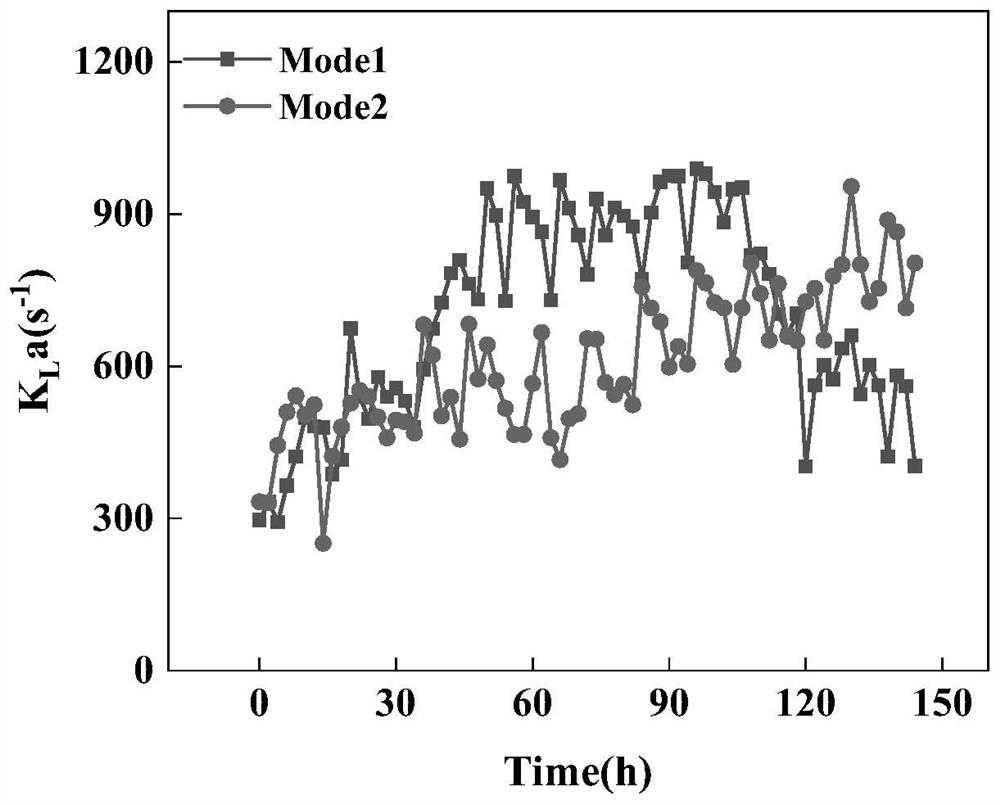

[0070]Fermentation culture: inoculate the seed liquid into the fermentation medium according to the inoculum amount of 10%, set the culture temperature to 28°C, the initial rotation speed to 300rpm, and the ventilation to 1vvm to maintain the pressure of the reaction vessel at 0.03-0.04MPa, and calibrate The DO electrode (dissolved oxygen electrode) is full, and fermented; after the fermentation, the fermentation broth is obtained, that is, the Rhizomucor miehei lipase is obtained.

[0071] In this embodiment, duri...

Embodiment 2

[0077] The present embodiment provides a method for efficient production of Rhizomucor miehei lipase by Aspergillus oryzae, comprising steps:

[0078] Seed culture: inoculate the spore suspension of Aspergillus oryzae in the seed medium according to the inoculation amount of 0.6%, and cultivate it for 28 hours at a temperature of 28°C and a rotation speed of 150rpm to obtain a seed liquid; wherein, the spore suspension The concentration of spores is 4×10 5 a / mL;

[0079] Fermentation culture: inoculate the seed liquid into the fermentation medium according to the inoculum amount of 10%, set the culture temperature to 28°C, the initial rotation speed to 300rpm, and the ventilation to 1vvm to maintain the pressure of the reaction vessel at 0.03-0.04MPa, and calibrate The DO electrode (dissolved oxygen electrode) is full, and fermented; after the fermentation, the fermentation broth is obtained, that is, the Rhizomucor miehei lipase is obtained.

[0080] In this embodiment, dur...

Embodiment 3

[0086] The present embodiment provides a method for efficient production of Rhizomucor miehei lipase by Aspergillus oryzae, comprising the steps of:

[0087] Spread the spores of Aspergillus oryzae on the potato dextrose agar (PDA) medium and culture them at 28°C for 2 days, pick a single colony with better growth and continue to culture it on a new PDA plate for 7 days, and some colonies with spores (green) Scrape the spores in a test tube filled with sterile water and glass beads to elute, filter through a sterile funnel, count the spores using a hemocytometer, and then dilute the obtained spore suspension with sterile water to the required spore concentration. Store in refrigerator at 4°C for later use.

[0088] Under sterile conditions, take 300 μL of the spore suspension and add it to the seed shake flask with the seed culture solution. The liquid volume of the shake flask is 20%, and cultivate it for 28 hours at a temperature of 28 ° C and a rotation speed of 150 rpm to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com