Comprehensive recovery method for arsenic and antimony smoke dust

A recovery method and smoke dust technology, applied in the direction of instrumentation, optics, process efficiency improvement, etc., can solve the problems of inability to completely separate arsenic and antimony, unfavorable industrialization promotion, and high cost of chemicals, so as to save the cost of chemicals, reduce processing costs, reduce The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

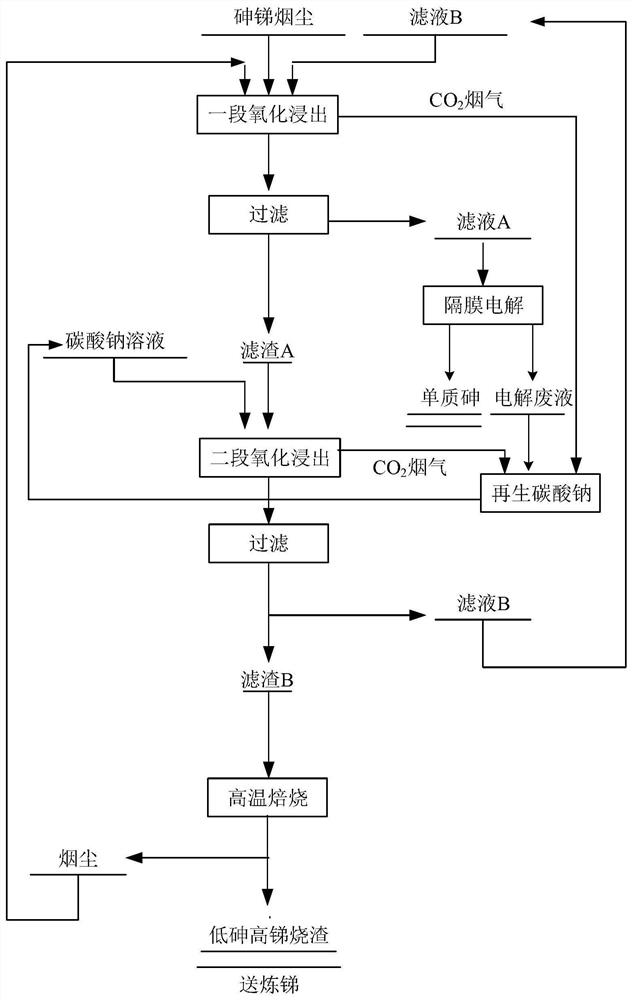

[0038] A kind of processing method of arsenic antimony smoke dust of the present invention, its process flow schematic diagram is as figure 1 As shown, the object of processing is the arsenic-antimony smoke dust (the mass content of As is 12.7%, and the mass content of Sb is 44.26%) produced by a gold and silver workshop of a lead smelter, including the following steps:

[0039] (1) Add arsenic and antimony fumes to the sodium carbonate solution, heat up to 100° C., carry out a stage of oxidation leaching for 2 hours under air stirring conditions, the pH value at the end of the reaction is 8, and obtain filtrate A and filter residue A after filtration;

[0040] (2) Add filter residue A to 20% sodium carbonate solution, heat up to 95°C, carry out two-stage oxidation leaching for 3 hours under air stirring and microwave radiation conditions, the frequency of microwave is 2450MHz, and obtain filtrate B and filter residue B after filtration ; The content of arsenic and antimony in...

Embodiment 2

[0044] A method for processing arsenic-antimony fumes of the present invention, the object of treatment is the arsenic-antimony fumes (the mass content of As is 24.15%, and the mass content of Sb is 49.78%) produced by a Xigui workshop of a lead smelter, comprising the following steps:

[0045] (1) Add arsenic and antimony fumes to the sodium carbonate solution, heat up to 100° C., carry out a stage of oxidation leaching for 2 hours under air stirring conditions, the pH value at the end of the reaction is 9, and obtain filtrate A and filter residue A after filtration;

[0046] (2) Add filter residue A to 20% sodium carbonate solution, heat up to 95°C, carry out two-stage oxidation leaching for 3 hours under air stirring and microwave radiation conditions, the frequency of microwave is 2450MHz, and obtain filtrate B and filter residue B after filtration ; The content of arsenic and antimony in the filter residue B is detected, the mass content of As is 3.94%, and the mass conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com