Corrosion protection method for supercritical generator set

A technology of supercritical unit and generator set, applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of reduced service life of equipment, explosion, and reduction of boiler tube strength, so as to prevent excessive consumption , high bonding strength, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A corrosion protection method for a supercritical generating set of the present invention is specifically implemented according to the following steps:

[0038] Step 1. For supercritical generator sets using TP347H steel, preheat the generator set at 180°C before starting up or after pickling and descaling.

[0039] Step 2. Introduce oxygen into the preheated unit, the pressure of oxygen is 0.05Mpa, keep warm for 1h.

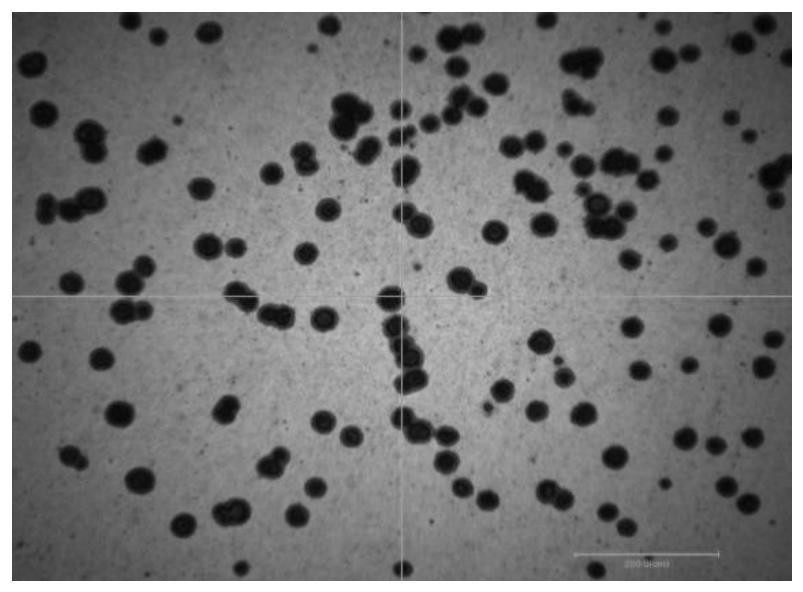

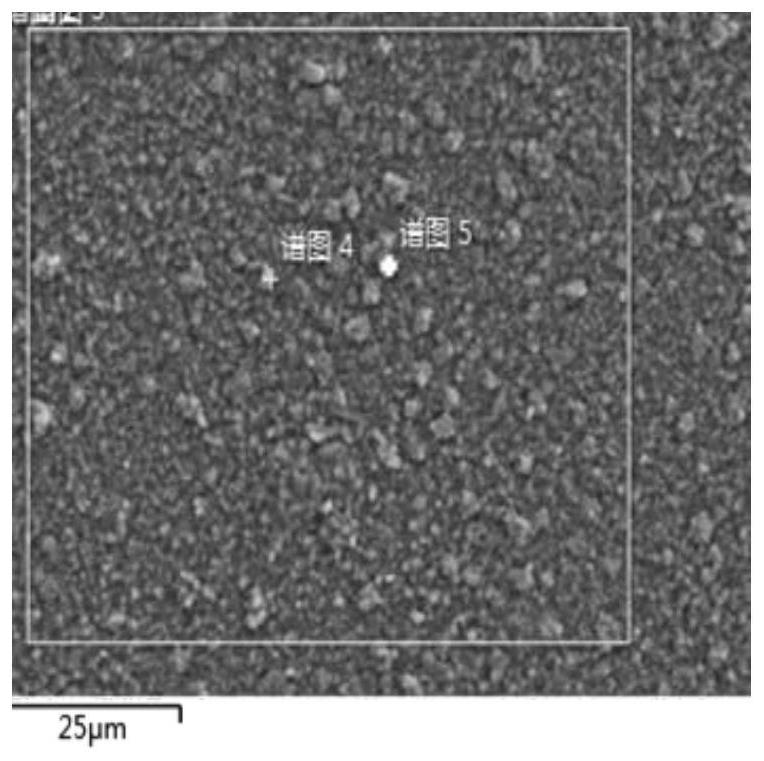

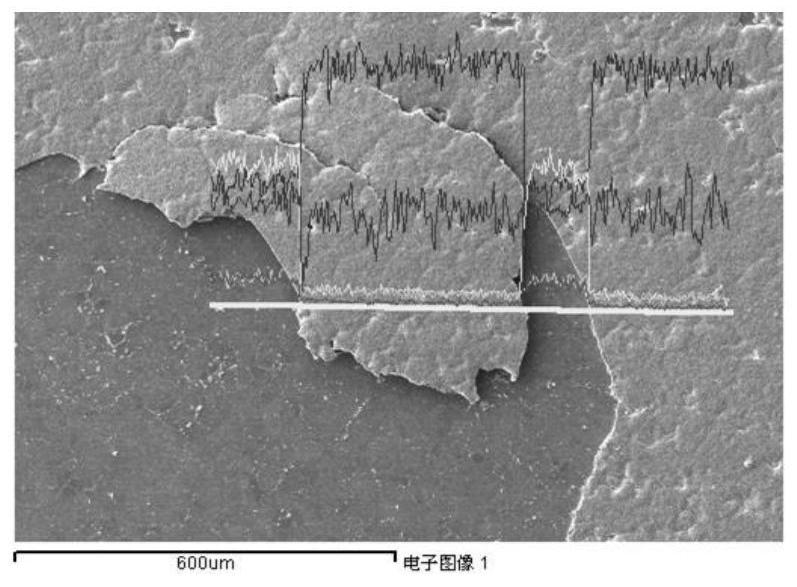

[0040] Step 3. Introduce ozone into the preheated unit, the partial pressure of ozone is 0.01Mpa, and keep warm for 0.5h. An oxide layer with an oxide film thickness of about 0.2 μm is prepared.

[0041] Step 4. Exhaust the gas in the boiler tube, inject water into the boiler or unit, and the boiler can operate according to the normal power generation process.

Embodiment 2

[0043] A corrosion protection method for a supercritical generating set of the present invention is specifically implemented according to the following steps:

[0044] Step 1. For the supercritical generator set using TP347H steel, preheat the generator set at 190°C before starting up or after pickling and descaling.

[0045] Step 2. Introduce oxygen into the preheated unit, the pressure of oxygen is 0.08Mpa, keep warm for 1.2h.

[0046] Step 3. Introduce ozone into the preheated unit, the partial pressure of ozone is 0.015Mpa, and keep warm for 0.8h. An oxide layer with an oxide film thickness of about 0.22 μm was prepared.

[0047] Step 4. Exhaust the gas in the boiler tube, inject water into the boiler or unit, and the boiler can operate according to the normal power generation process.

Embodiment 3

[0049] A corrosion protection method for a supercritical generating set of the present invention is specifically implemented according to the following steps:

[0050] Step 1. For the supercritical generator set using TP347H steel, preheat the generator set at 200°C before starting up or after pickling and descaling.

[0051] Step 2. Introduce oxygen into the preheated unit, the pressure of oxygen is 0.1Mpa, keep warm for 1.5h.

[0052] Step 3: Introduce ozone into the preheated unit, the partial pressure of ozone is 0.02Mpa, keep warm for 1 hour, and prepare an oxide layer with an oxide film thickness of about 0.3 μm.

[0053] Step 4. Exhaust the gas in the boiler tube, inject water into the boiler or unit, and the boiler can operate according to the normal power generation process.

[0054] The present invention adopts the pre-oxidation technology, before starting up the new supercritical unit or after cleaning the corrosion product of the used supercritical unit, a dense o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com