Si-based AlGaN/GaN high-electron-mobility transistor with wrapping buried layer and preparation method

A technology with high electron mobility and transistors, applied in transistors, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing radio frequency loss, lower substrate resistivity, and large radio frequency loss, so as to reduce radio frequency loss and improve substrate Effect of bottom resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

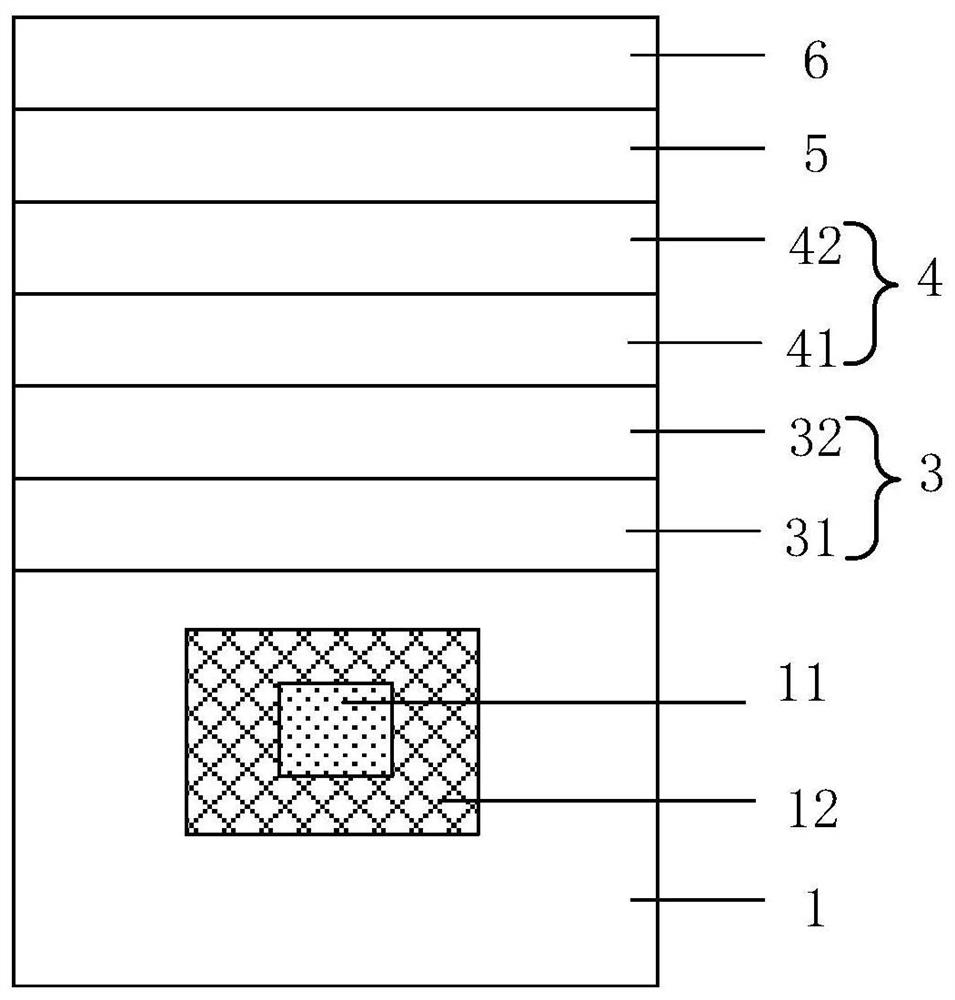

[0029] See figure 1 , figure 1 A structural diagram of a Si-based AlGaN / GaN high electron mobility transistor having a wrapped embedded layer is provided for an embodiment of the present invention.

[0030] The AlGaN / GaN high electron mobility transistor includes a Si substrate 1, AlN-ring-based 3, AlGa-step becomings 4, a GaN buffer layer 5, and a AlGa barrier layer 6, wherein the Si substrate 1 is provided in the Si substrate 1. The n-type buried layer 11 and the isolation layer 12 are disposed between the Si substrate 1 and the n-type buried layer 11 and wrap the N-type buried layer.

[0031] In this embodiment, the n-type buried layer 11 and the spacer layer 12 are each disposed in the Si substrate 1, i.e., the spacer layer 12 is wrapped in the four weeks of the n-type buried layer 11, and the Si substrate 1 is wrapped around the spacer 12. The arrangement of the isolation layer 12 satisfies the following conditions: The isolation layer 12 does not cover the n-type impurit...

Embodiment 2

[0053] On the basis of the first example, see Figure 3A-Figure 3F , Figure 3A-Figure 3F A process diagram of a method of preparing a Si-based AlGaN high electron mobility transistor having a wrap-embedding layer, wherein the preparation method comprises the step of:

[0054] S1, prepare the first isolation sublayer 121 in the Si sheet 13, see Figure 3A and Figure 3B .

[0055] First, the Si sheet 13 is placed in a 20% HF acid solution soaking 60s, and then h 2 O 2 , Alcohol and acetone cleaning, and finally rinse 60s using flowing deionized water.

[0056] Then, the cleaned substrate was placed in a low pressure MoCVD reaction chamber, and hydrogen gas was passed, the temperature was raised to 950-1010 ° C, and the reaction chamber pressure was controlled to 40 torr, and the substrate was heat for 3 min under a hydrogen atmosphere.

[0057] Next, after the heat cleaning phase, the reaction chamber temperature is lowered to room temperature, and the Si sheet 13 is taken out, and th...

Embodiment 3

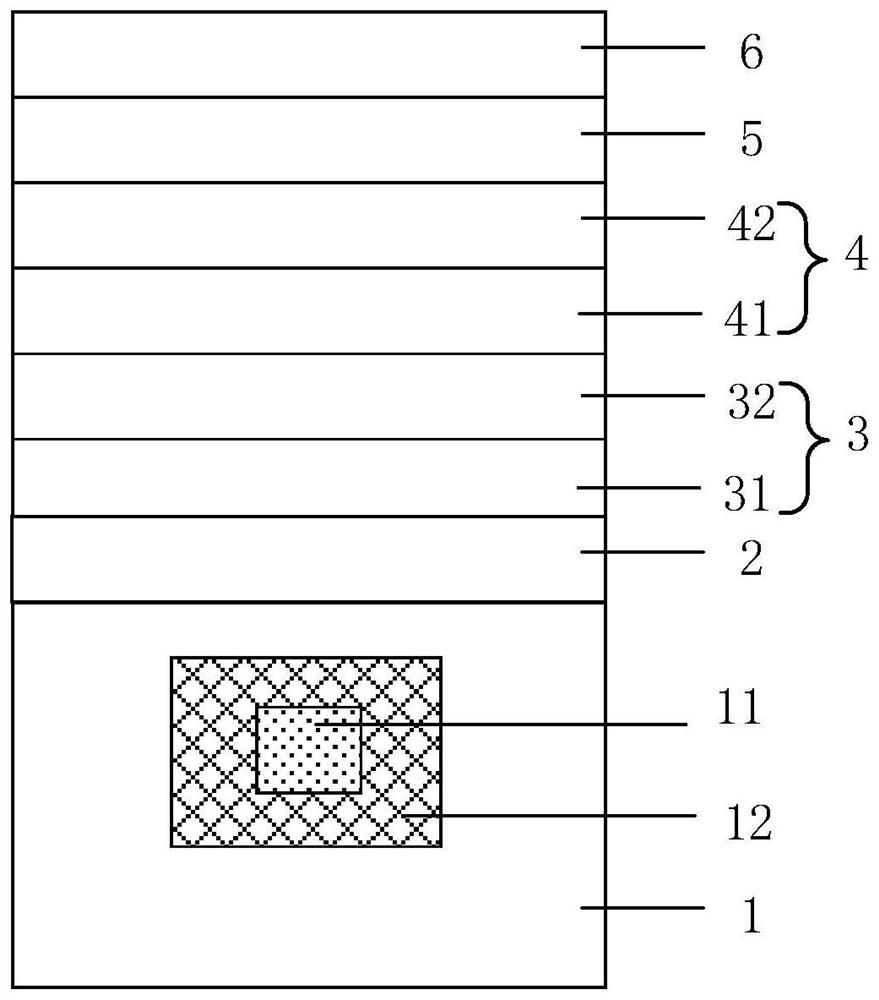

[0090] Based on the second embodiment, please figure 2 In this embodiment, another method of preparing another Si-based AlGaN high electron mobility transistor with a wrap layer, the preparation method comprising the step of:

[0091] S1, the first isolation sublayer 121 is prepared in the Si sheet 13.

[0092] S2, ionically implantation of the surface layer of the first isolation sublayer 121, forming the n-type buried layer 11.

[0093] S3, the second isolation sublayer 122 is grown on the first spacer layer 121 and the n-type buried layer 11 to form the isolation layer 12.

[0094] S4, a single crystal silicon 14 is grown on the Si sheet 13 and the second spacer 122 to form a Si substrate 1.

[0095] S5, preparing a pre-paved aluminum layer 2 on the Si substrate 1.

[0096] Specifically, the reaction chamber temperature is raised to 1080-1090 ° C, the TMAL air train is opened, and the TMAL flow rate is 10-30 Sccm, the preparation of the pre-pavomate layer 2 is performed, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com