Ferrocenyl macrocyclic composite burning rate catalyst and preparation method and application thereof

A burning rate catalyst, ferrocene-based technology, applied in the direction of offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve problems such as difficult to achieve synthetic applications, compatibility problems, complex processes, etc., to reduce sublimation And migration performance, improved stability, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of preparation method of ferrocene-based macrocyclic composite burning rate catalyst, specifically comprises the following steps:

[0031] 1) Weigh 115 mg of β-cyclodextrin, dissolve it in 50 ml of water, and prepare a 2.0 mM aqueous solution of hydroxypropyl cyclodextrin;

[0032] 2) Take the burning rate catalyst Catoxin at a molar ratio of 1:1, add it to the hydroxypropyl β-cyclodextrin solution in step 1) under stirring, and continue to stir and react for 12 hours to obtain Cato Octyl β-cyclodextrin composite burning rate catalyst solution;

[0033] 3) Freeze-drying the solution of the composite burning rate catalyst in step 2) to remove the water solvent to obtain a brown cathecin hydroxypropyl β-cyclodextrin composite burning rate catalyst.

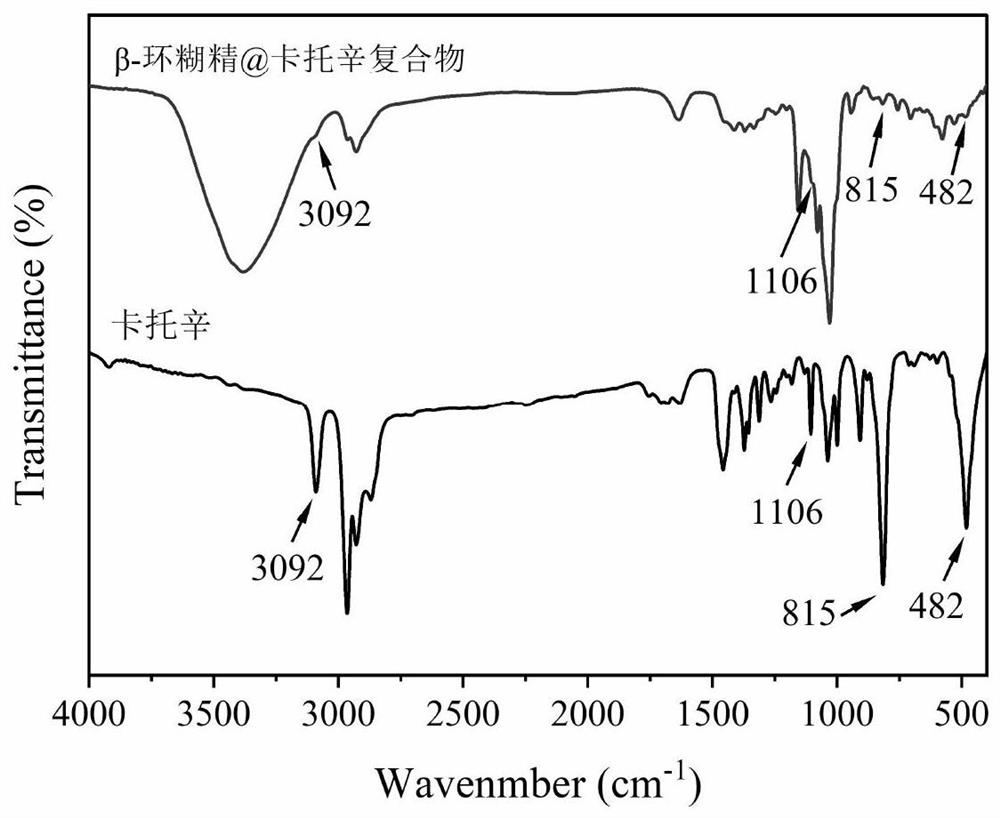

[0034] Through the infrared spectrum characterization of the powder in step 3), it was found that the infrared spectrum ( figure 1 ) shows the characteristic peak of ferrocene (3090 cm -1 , 1106 cm -1...

Embodiment 2

[0035] Embodiment 2: a kind of preparation method of ferrocene-based macrocyclic composite burning rate catalyst, specifically comprises the following steps:

[0036] 1) Weigh 130 mg of γ-cyclodextrin and dissolve it in 50 ml of water to prepare a 2.0 mM aqueous solution of hydroxypropyl cyclodextrin;

[0037] 2) Take the burning rate catalyst Catoxin at a molar ratio of 1:1, add it to the hydroxypropyl β-cyclodextrin solution in step 1) under stirring, and continue to stir and react for 12 hours to obtain Cato Octylic γ-cyclodextrin composite burning rate catalyst solution;

[0038] 3) Freeze-drying the solution of the composite burning rate catalyst in step 2) to remove the water solvent to obtain a brown cathecin hydroxypropyl β-cyclodextrin composite burning rate catalyst.

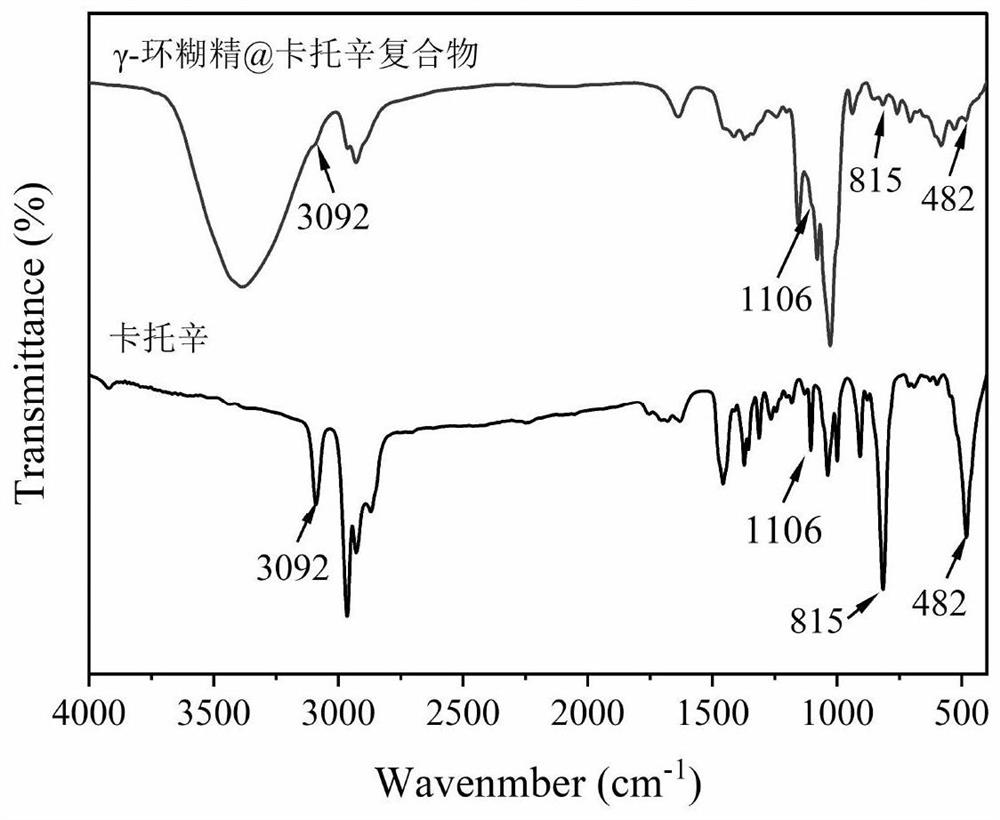

[0039] Through the infrared spectrum characterization of the powder in step 3), it was found that the infrared spectrum ( figure 2 ) shows the characteristic peak of ferrocene (3090 cm -1 , 1106 cm...

Embodiment 3

[0040] Embodiment 3: a kind of preparation method of ferrocene-based macrocyclic composite burning rate catalyst, specifically comprises the following steps:

[0041] 1) Weigh 120 mg of cucurbit[7]uril and dissolve it in 50 ml of water to prepare a 2.0 mM aqueous solution of cucurbit[7]uril;

[0042] 2) Take the burning rate catalyst Catosine according to the molar ratio of 1:1, add it to the cucurbit [7] urea solution in step 1) under stirring, and continue to stir and react for 12 hours to obtain Catosine [ 7] urea composite burning rate catalyst solution;

[0043] 3) Freeze-drying the composite burning rate catalyst solution in step 2) to remove the water solvent to obtain a brown catosine cucurbit [7] urea composite burning rate catalyst.

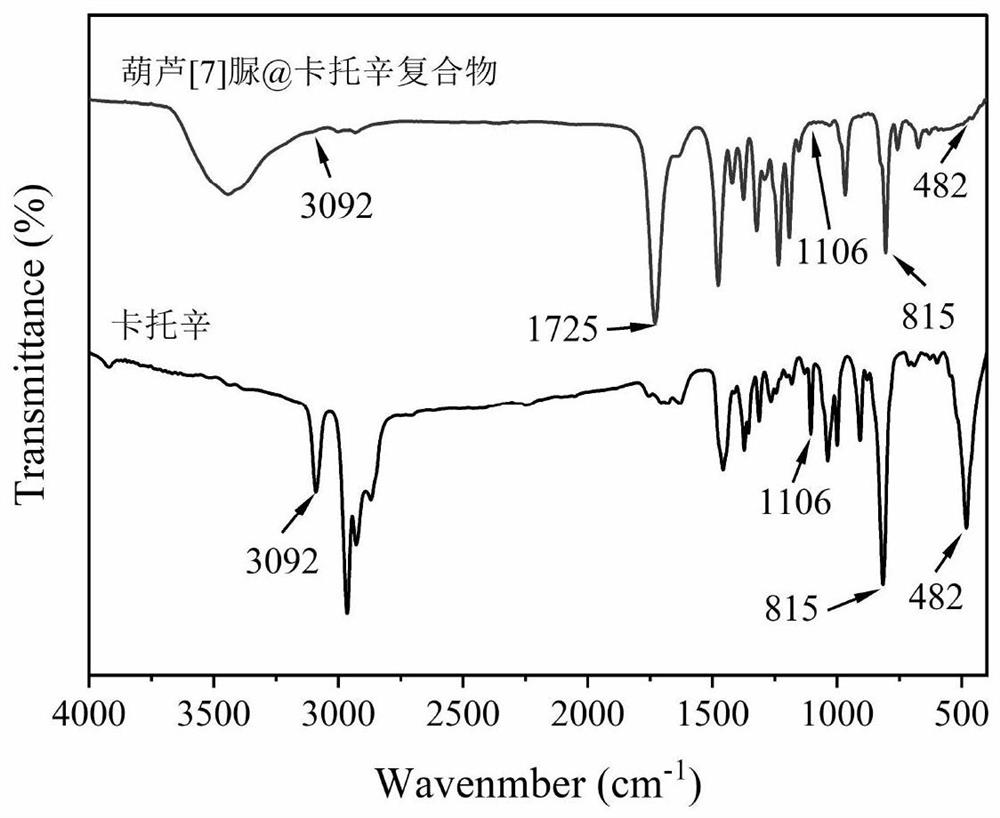

[0044] Through the infrared spectrum characterization of the powder in step 3), it was found that the infrared spectrum ( image 3 ) shows the characteristic peak of ferrocene (3090 cm -1 , 1106 cm -1 , 815 cm -1 ,482 cm -1 ) sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com