Waterworks sludge water sludge dewatering process self-control treatment method

A sludge dewatering and water plant technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. High-level problems, to achieve the effect of realizing water resource recycling and saving utilization, reducing project investment and reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] Provided is a waterworks sludge water sludge dewatering process automatic control treatment method for treating waterworks sludge water and sludge concentration, including the following steps:

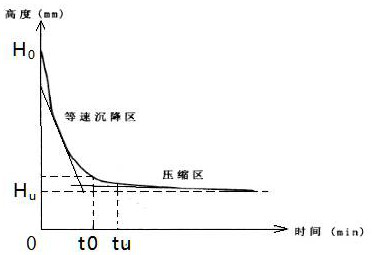

[0100] S1: Through the analysis of the sludge properties and the static sedimentation test, the sedimentation conditions are obtained;

[0101] S2: Determine the most suitable type and dosage of the drug through the test of the drug;

[0102] S3: The high-efficiency sedimentation concentration tank is adopted, and the high-efficiency sedimentation concentration tank is combined with the inclined plate sedimentation to increase the solid content of the sludge in the bottom concentration area and directly enter the dehydration process to improve the concentration efficiency;

[0103] S4: Through the floating mud-water separation device, the amount of sludge water entering the subsequent equipment is reduced.

[0104] In a preferred embodiment, in step S1, the method for the follo...

Embodiment 2

[0161] A self-control treatment method for sludge dewatering process of waterworks sludge, used for treating sludge discharge and sludge concentration in waterworks, comprising the following steps:

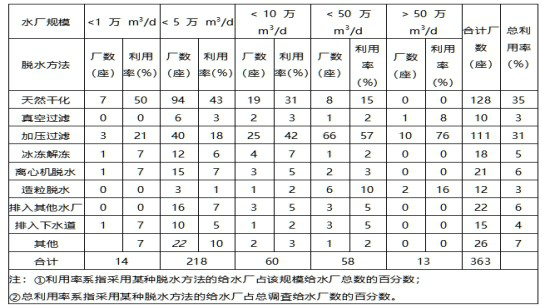

[0162] (1) Through the analysis and research on the concentration equipment, it is determined to replace the traditional sludge concentration tank with a high-efficiency sedimentation concentration tank to reduce the land occupation of the water purification plant and improve the concentration efficiency.

[0163] In order to solve the large area occupied by the traditional process and meet the needs of the construction of existing water plants, especially the transformation needs of the completed water plants, the requirements for the land occupation of the selected process are very strict. The thickening tank is the key structure for the success of sludge treatment. Since the sludge produced by the waterworks with surface water as the water source is not easy to concentrate, if t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com