A thick-film silver-palladium conductor paste for wear-resistant and high-precision oil level sensors

A technology of oil level sensor and conductor slurry, which is applied in the direction of testing wear resistance, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., and can solve the disorder of the electrical signal of the oil level sensor and the wrong indication of the oil gauge , conduction band resistance becomes larger, etc., to improve accuracy and long-term reliability, ensure reliability, reduce wear and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

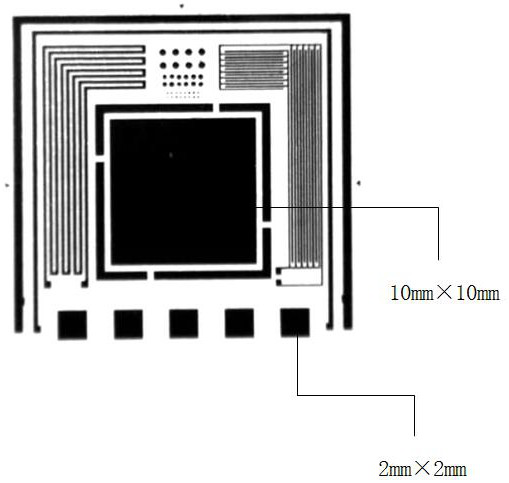

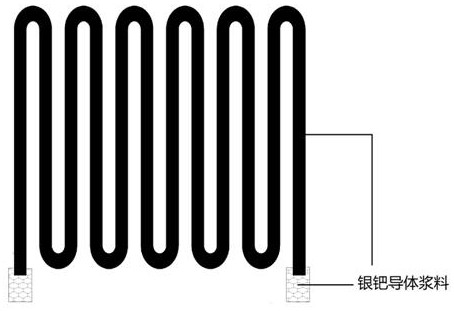

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, which do not limit the protection scope of the present invention. The protection scope of the present invention is only limited by the claims, and any omission, replacement or modification made by those skilled in the art on the basis of the disclosed embodiments of the present invention will fall within the protection scope of the present invention.

[0017] 1. Preparation of pretreated polycrystalline cubic boron nitride powder

[0018] Mix polycrystalline cubic boron nitride powder with a particle size of 1.5-2.5 μm and absolute ethanol at a mass ratio of 1:1, ultrasonicate in an ultrasonic machine for 30 minutes, ultrasonic temperature is 50°C, and ultrasonic power is 1kW, and then use a 400-mesh screen to Sieve, bake at 500° C. for 3 hours, and then sieve with a 400-mesh sieve to obtain pretreated polycrystalline cubic boron nitride powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com