Microcrystalline peptide anti-wrinkle face cream and preparation method thereof

A face cream and microcrystalline technology, applied in the field of daily chemical products, can solve problems such as skin sensitivity and excessive exfoliation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

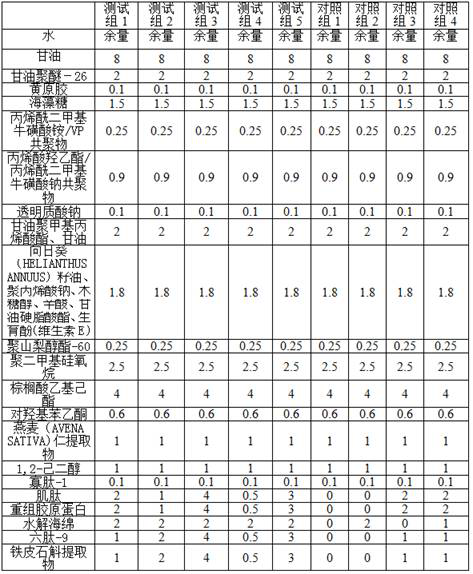

[0056] Each component is weighed according to the weight percentage of the following table:

[0057]

[0058] After weighing, homogenize the materials of group A at a speed of 20-25r / min for 2-3 minutes, and heat the materials to 80-85°C to dissolve them completely; after the materials of group A are dissolved, heat the materials of group B to After 80-85°C, put it into the dissolved group A materials, homogenize at a speed of 20-25r / min for 3-4min, after homogenization, stir and keep at a speed of 20-30r / min for 20-30min; The material is naturally cooled. When the temperature drops to 65-70°C, put the C group of materials into the material, and stir at a speed of 20-30r / min for 10-15min to make it evenly stirred; after stirring evenly, continue to naturally cool down the material , when the temperature drops to 40-45°C, put the materials of group D into the materials, stir at a speed of 20-30r / min for 15-20min, test, filter and discharge the obtained materials in sequence, a...

Embodiment 2

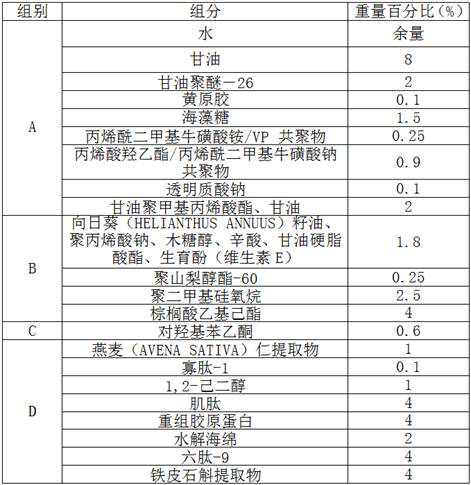

[0060] Each component is weighed according to the weight percentage of the following table:

[0061]

[0062] After weighing, homogenize the materials of group A at a speed of 20-25r / min for 2-3 minutes, and heat the materials to 80-85°C to dissolve them completely; after the materials of group A are dissolved, heat the materials of group B to After 80-85°C, put it into the dissolved group A materials, homogenize at a speed of 20-25r / min for 3-4min, after homogenization, stir and keep at a speed of 20-30r / min for 20-30min; The material is naturally cooled. When the temperature drops to 65-70°C, put the C group of materials into the material, and stir at a speed of 20-30r / min for 10-15min to make it evenly stirred; after stirring evenly, continue to naturally cool down the material , when the temperature drops to 40-45°C, put the materials of group D into the materials, stir at a speed of 20-30r / min for 15-20min, test, filter and discharge the obtained materials in sequence,...

Embodiment 3

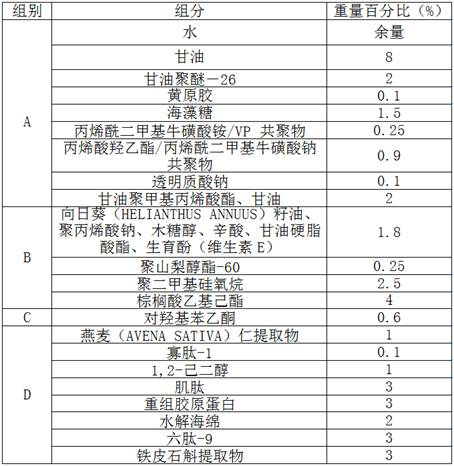

[0064] Each component is weighed according to the weight percentage of the following table:

[0065]

[0066] After weighing, homogenize the materials of group A at a speed of 20-25r / min for 2-3 minutes, and heat the materials to 80-85°C to dissolve them completely; after the materials of group A are dissolved, heat the materials of group B to After 80-85°C, put it into the dissolved group A materials, homogenize at a speed of 20-25r / min for 3-4min, after homogenization, stir and keep at a speed of 20-30r / min for 20-30min; The material is naturally cooled. When the temperature drops to 65-70°C, put the C group of materials into the material, and stir at a speed of 20-30r / min for 10-15min to make it evenly stirred; after stirring evenly, continue to naturally cool down the material , when the temperature drops to 40-45°C, put the materials of group D into the materials, stir at a speed of 20-30r / min for 15-20min, test, filter and discharge the obtained materials in sequence,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com