Preparation method and application of nano preparation hydrogel

A hydrogel and micelle technology, applied in nanotechnology, nanotechnology, nanomedicine, etc., can solve the problems of poor water solubility of gambogic acid, obvious side effects, and poor curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the gambogic acid micellar hydrogel provided by the present embodiment is as follows:

[0036] Gambogic acid micelles were mixed with 20 wt% PDLLA-PEG-PDLLA hydrogel at a volume ratio of 1:9 to obtain gambogic acid micellar hydrogels.

[0037]PBS was mixed with 20 wt% PDLLA-PEG-PDLLA hydrogel at a volume ratio of 1:9 to obtain a blank PLEL hydrogel.

[0038] Wherein, the preparation method of gambogic acid micelles used is as follows:

[0039] Preparation of entrapped gambogic acid and methoxypolyethylene glycol-polycaprolactone (mPEG) by film hydration method (solid dispersion method) 2000 - Gambogic acid micelles (GA-MIC micelles) of PCL) polymers. Weigh gambogic acid: mPEG 2000 -The mass ratio of PCL polymer is 5:95, 2.5mg gambogic acid and 47.5mg mPEG 2000 -PCL polymer was placed in a round bottom flask, and gambogic acid and mPEG were dissolved with 2 mL of acetone 2000 -PCL polymer, after completely dissolving, a yellow clear solutio...

Embodiment 2-7

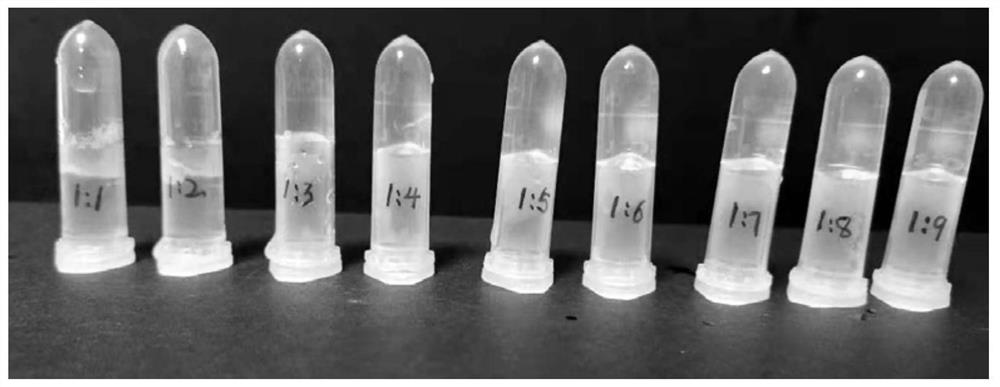

[0044] The preparation method of the gambogic acid micelle hydrogel that embodiment 2-7 provides is basically the same as the preparation method of embodiment 1, and difference is that the volume ratio of gambogic acid micelle and 20wt% PDLLA-PEG-PDLLA is different, See Table 1 below for details.

[0045] Table 1

[0046] Example Volume ratio 2 1:1 3 1:2 4 1:3 5 1:4 6 1:5 7 1:6 8 1:7 9 1:8

experiment example 1

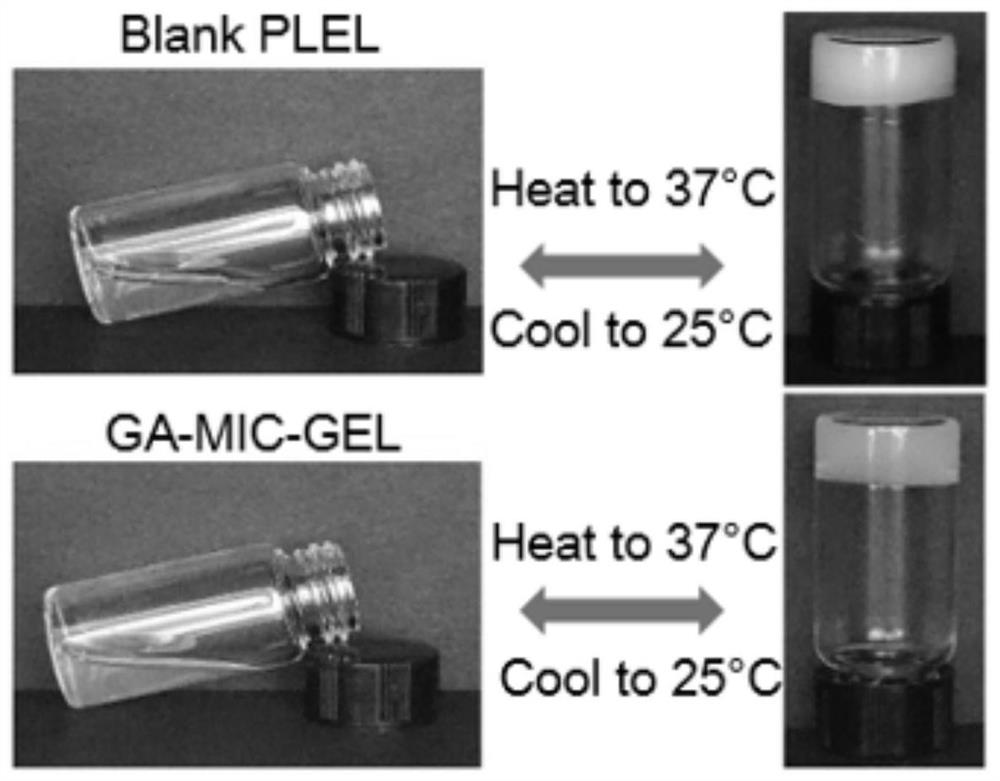

[0048] Investigate the phase transition state of the gambogic acid micellar hydrogel of embodiment 1-9

[0049] The test tube inversion method is used to determine the gelation of gambogic acid micellar hydrogel; the test tube is placed in a constant temperature water bath, and the sample is kept at a constant temperature for 10 minutes at 37 ° C; then it is inverted at 180 degrees to observe whether the sample has Flow phenomenon; if the sample does not flow, it is judged as a gel state, and if it flows, it is judged as a sol state.

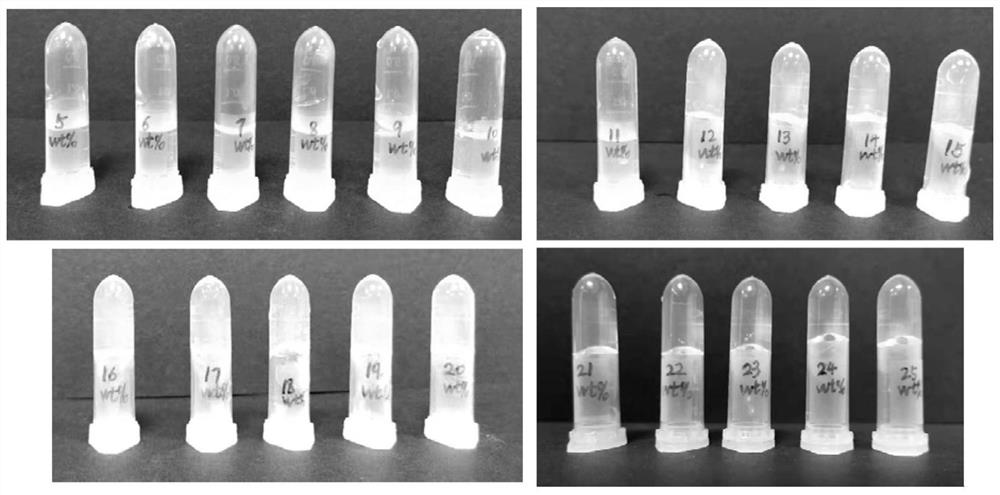

[0050] The results show that gambogic acid micelles are mixed with 20wt% PDLLA-PEG-PDLLA in a ratio of 1:3–9 (v / v), and all of them can be gelled, and the gambogic acid of Example 1 and Examples 4-9 The micellar hydrogel is a solution state at room temperature, and is a gel state at 37° C., and the gambogic acid micellar hydrogel in the gel state can recover a solution state at room temperature (see figure 1 with figure 2 ), this process is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com