Preparation method of super-hydrophobic anti-fouling and anti-drag material

A super-hydrophobic and anti-fouling technology, applied in metal material coating process, liquid chemical plating, superimposed layer plating, etc. State and other problems, to achieve the effect of reducing biological adhesion, reducing the contact area, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

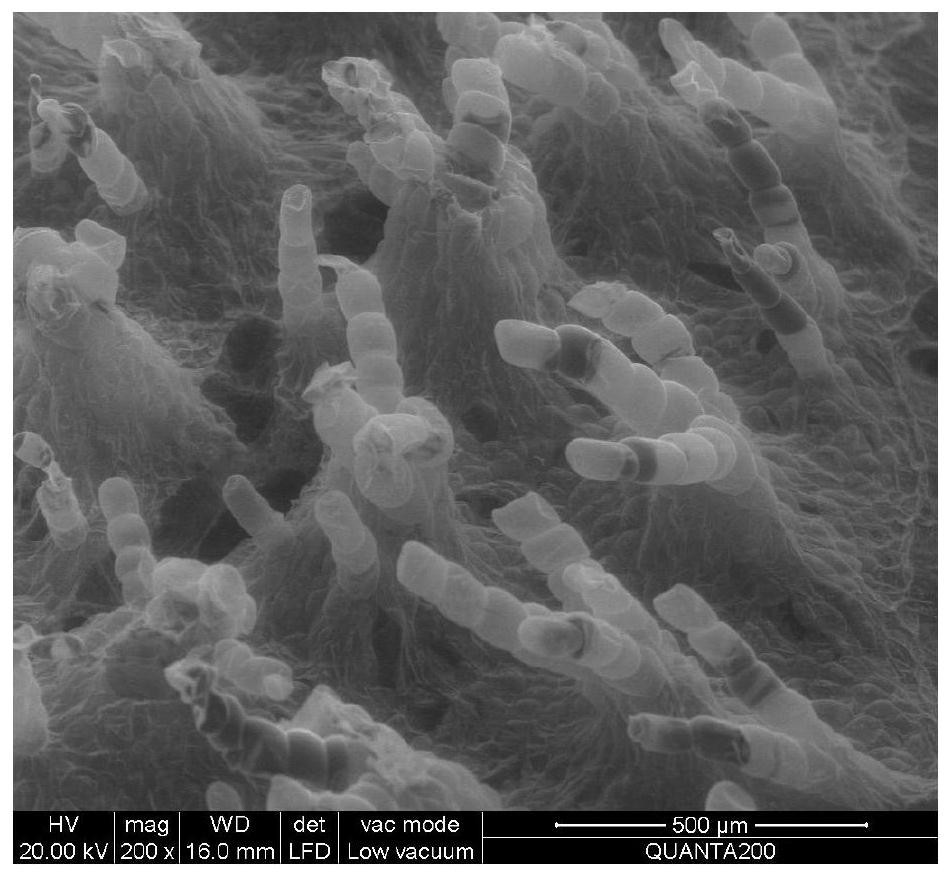

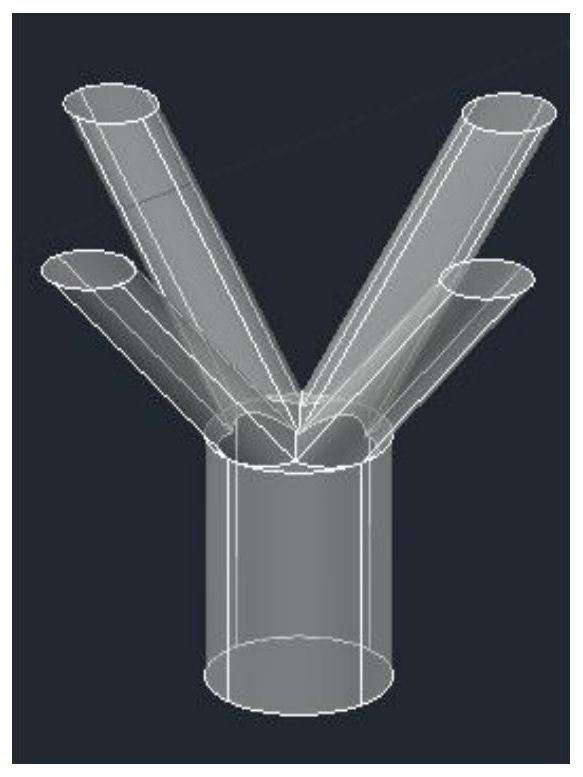

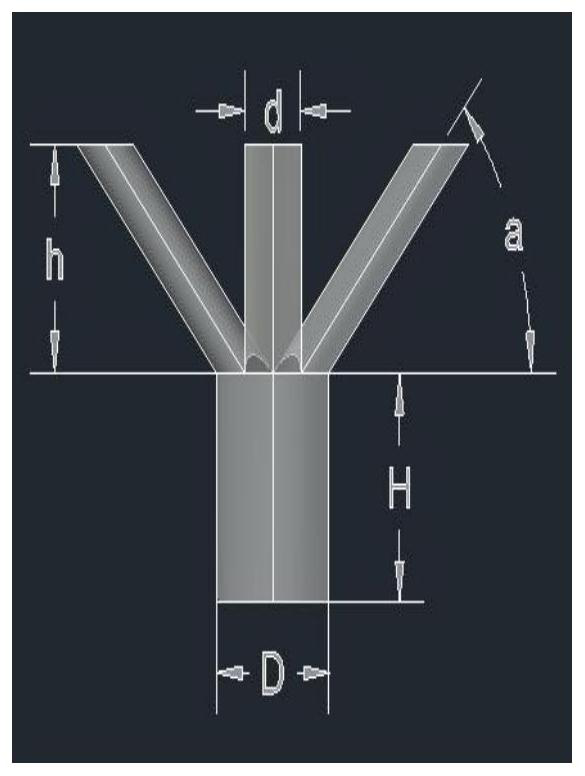

[0038] The process of the super-hydrophobic anti-fouling and drag-reducing material involved in the present invention includes three steps of preparing a bionic "claw-shaped" structure substrate, preparing a multi-level structure and preparing a super-hydrophobic anti-fouling and drag-reducing material:

[0039] (1) Preparation of biomimetic "claw" structure matrix

[0040] Using ABS resin as raw material, use a 3D printer to print a number of bionic "claw-shaped" structural substrates that combine microstructure monomers arranged in an equilateral triangular lattice with a base, and the distance between any two adjacent microstructure monomers Both are 3000μm;

[0041] The microstructure monomer is divided into upper and lower parts, the lower part is a cylinder, and the upper part is a "claw-shaped" structure composed of four oblique cylinders with different directions. The bottom of the cylinder is connected to the base. The top is connected to the "claw" structure. The di...

Embodiment 2

[0049] This example relates to the surface wettability test of the super-hydrophobic anti-fouling and drag-reducing material prepared in Example 1. Using running water to wash the surface of the super-hydrophobic, anti-fouling and drag-reducing material, it can be seen that no water drops remain on the surface of the super-hydrophobic, anti-fouling and drag-reducing material , indicating that the super-hydrophobic anti-fouling and drag-reducing material has a small rolling angle and a large water contact angle; when the super-hydrophobic anti-fouling and drag-reducing material is placed in water, the surface of the super-hydrophobic anti-fouling and drag-reducing material can be clearly seen It has a layer of silver-white light film, which is the underwater air layer of the super-hydrophobic anti-fouling and drag-reducing material, which shows that the super-hydrophobic anti-fouling and drag-reducing material itself has super-hydrophobic properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com