Full-biodegradable plastic composite modified material suitable for film bag and preparation method of full-biodegradable plastic composite modified material

A technology for degrading plastic and compound modification, applied in the field of fully biodegradable plastic compound modification materials and their preparation, can solve the problems of low elongation at break, research on printing performance, and high price of PBAT, and achieve improved printing performance and screw filling. The effect of high degree and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

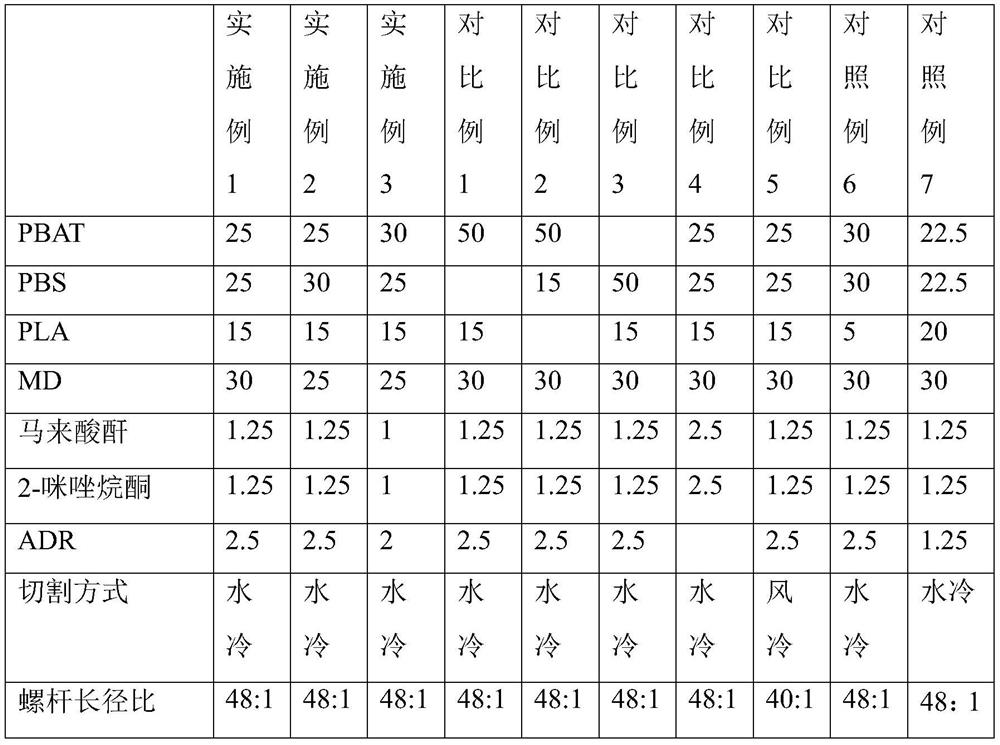

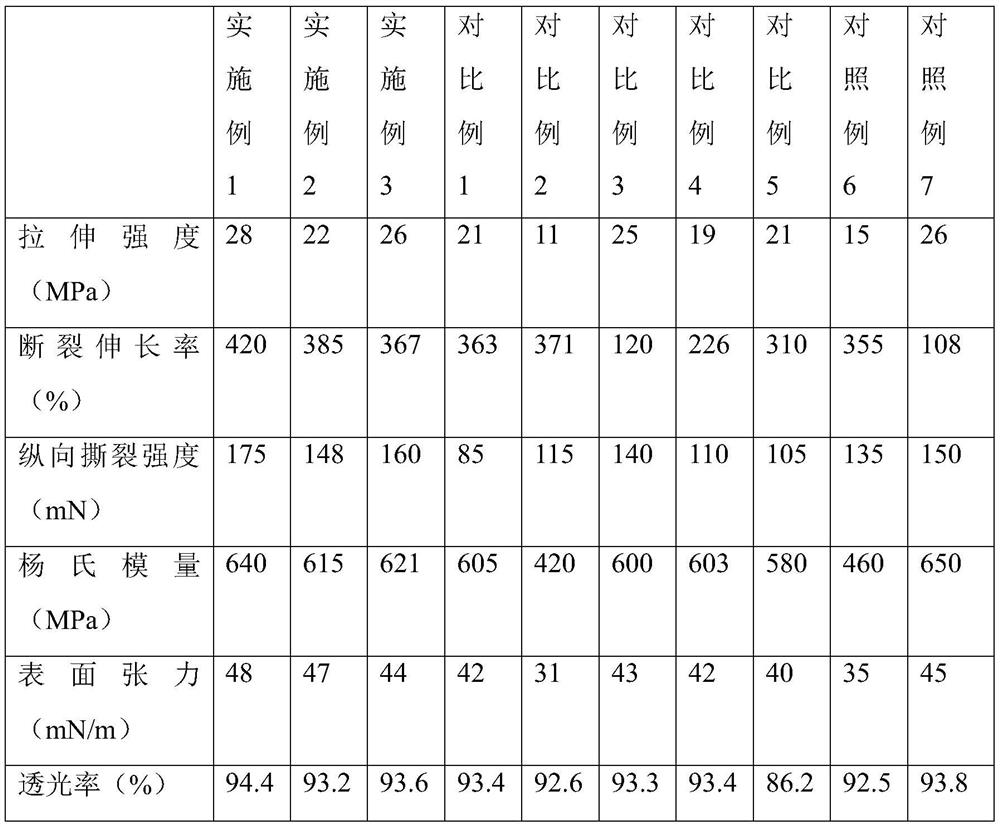

Embodiment 1

[0052] The fully biodegradable plastic composite modified material suitable for film bags provided in this embodiment is mainly made of the following raw materials in mass percentage:

[0053] Poly(butylene adipate / terephthalate) (PBAT): 25%;

[0054] Polybutylene succinate (PBS): 25%

[0055] Polylactic acid (PLA): 15%;

[0056] Calcium carbonate (MD): 30%;

[0057] Auxiliary: 5%;

[0058] The auxiliary agent is maleic anhydride, 2-imidazolidinone and styrene-glycidyl acrylate copolymer (ADR), and the mass ratio of the three is 0.5:0.5:1.

[0059] Its preparation method is as follows:

[0060] (1) Select polybutylene adipate / terephthalate (PBAT), polylactic acid (PLA), polybutylene succinate (PBS), calcium carbonate (MD) and the total mass of additives 80% additives, pre-mixed in high speed mixer (1000rpm) for 5 minutes;

[0061] (2) Add the remaining additives to the low-speed mixer (300rpm) for 4 minutes of secondary premixing;

[0062] (3) Put the homogeneously mixe...

Embodiment 2

[0065] The fully biodegradable plastic composite modified material suitable for film bags provided in this embodiment is mainly made of the following raw materials in mass percentage:

[0066] Poly(butylene adipate / terephthalate) (PBAT): 25%;

[0067] Polybutylene succinate (PBS): 30%

[0068] Polylactic acid (PLA): 15%;

[0069] Calcium carbonate (MD): 25%;

[0070] Auxiliary: 5%;

[0071] The auxiliary agent is maleic anhydride, 2-imidazolidinone and styrene-glycidyl acrylate copolymer (ADR), and the mass ratio of the three is 0.5:0.5:1.

[0072] Its preparation method can refer to embodiment 1.

Embodiment 3

[0074] The fully biodegradable plastic composite modified material suitable for film bags provided in this embodiment is mainly made of the following raw materials in mass percentage:

[0075] Poly(butylene adipate / terephthalate) (PBAT): 30%;

[0076] Polybutylene succinate (PBS): 25%

[0077] Polylactic acid (PLA): 15%;

[0078] Calcium carbonate (MD): 25%;

[0079] Auxiliary: 5%;

[0080] The auxiliary agent is maleic anhydride, 2-imidazolidinone and styrene-glycidyl acrylate copolymer (ADR), and the mass ratio of the three is 0.5:0.5:1.

[0081] Its preparation method can refer to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com