Stainless steel composite plate for weathering-resistant steel bridge with low yield ratio

A low yield ratio, stainless steel technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of polluted environment, poor atmospheric corrosion resistance, etc., achieve high metallurgical bonding quality, improve resistance Corrosion performance, effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, the cladding material is ultra-low C stainless steel billet with micro-Ti added, the C content is 0.022%, and the Ti content is 0.015%. The specific components are shown in Table 1; shown. Finally, the thickness of the rolling base material is 58mm, the thickness of the cladding material is 2mm, and the stainless steel clad plate for weather-resistant steel bridges with a total thickness of 60mm.

[0023] The base material and cladding material continuous casting blanks are heated at a high temperature of 1230±20°C and then opened to the required size. After blanking, the upper surface of the base material is polished by abrasive belt to remove the surface oxide scale, and the entire surface of the board is completely exposed to the bright silver metallic luster; the cladding material does not need solid solution and pickling treatment, and its upper and lower surfaces are polished by abrasive belt, completely exposed For fresh metal, check that the...

Embodiment 2

[0026] In this example, the cladding material is a stainless steel blank with low C and added micro-Ti content. The C content is 0.030%, and the Ti content is 0.30%. Ti will preferentially combine with C to form TiC, which acts as a solid C and inhibits the combination of C and Cr to precipitate Cr. 23 C 6 , which improves the corrosion resistance of the cladding material. The specific composition of the cladding material is shown in Table 1. A certain amount of alloying elements such as Cr, Ni, and Cu are added to the substrate, and the atmospheric corrosion resistance index I=6.3. The specific composition is shown in Table 2. Finally, the thickness of the rolled base material is 5.5mm, the thickness of the cladding material is 0.5mm, and the stainless steel clad plate for weather-resistant steel bridges with a total thickness of 6mm.

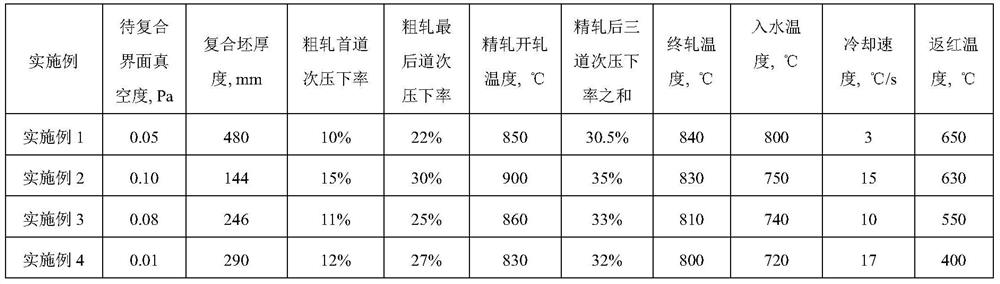

[0027] The production process of the composite plate is the same as that of Example 1. The total thickness of the composite billet, the vacu...

Embodiment 3

[0029] In this embodiment, the cladding material is selected from ultra-low C stainless steel blanks with added micro-Ti content. The C content is 0.010%, and the Ti content is 0.012%. Elements, atmospheric corrosion resistance index I = 6.6, the specific composition is shown in Table 2. Finally, the thickness of the rolling base material is 20mm, the thickness of the cladding material is 3mm, and the stainless steel clad plate for weather-resistant steel bridges with a total thickness of 23mm.

[0030] The total thickness of the composite billet, the vacuum degree of the interface between the cladding material and the base material, and the rolling and cooling parameters of the composite billet are shown in Table 3. The total thickness of the rolled clad plate is 46mm. The rolled clad plate is subjected to tempering heat treatment, the tempering temperature is 450°C, and the tempering time is 160min. After the tempered composite board is cut on four sides, the upper and low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com