Flexible glucose biosensor and preparation method thereof

A biosensor and glucose technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as poor stability, unsuitable for long-term use, and easy detachment of enzyme membranes, so as to achieve strong stability, avoid enzyme detachment, and enhance sensitivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The flexible glucose biosensor of the present invention includes a flexible substrate, a graphene interdigitated electrode prepared on the flexible substrate, a semiconductor carbon nanomaterial layer, a sensing enzyme film layer, and a blocking encapsulation layer sequentially covered on the graphene interdigitated electrode , and the solid-state electrode wires arranged on both sides of the interdigitated electrodes; wherein the sensing enzyme film layer is fixed on the semiconductor carbon nanomaterial layer through chemical cross-linking.

[0038] Further, an insulating hydrophobic layer is provided around the sensitive interface of the graphene interdigitated electrode. Optionally, the flexible substrate is polyimide (PI) or PDMS. The optional interdigitated electrodes have a single finger width ranging from 200 to 450 μm, and a finger spacing ranging from 50 to 150 μm.

Embodiment 2

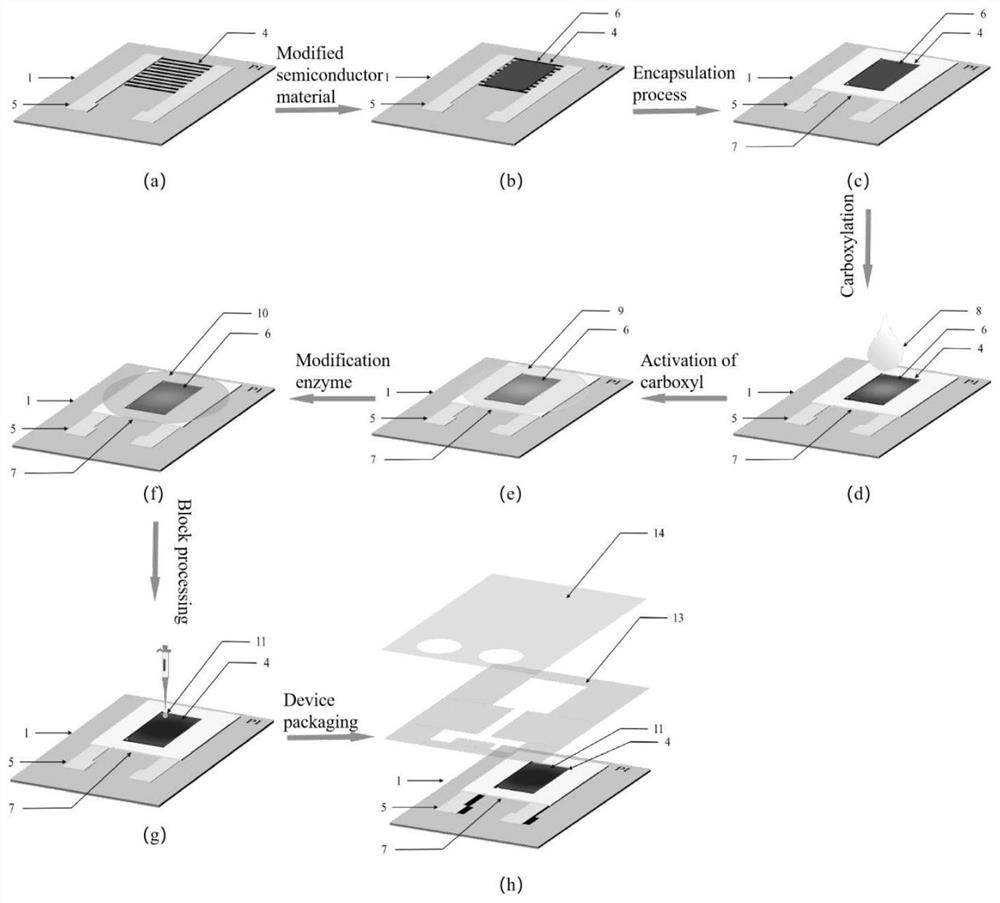

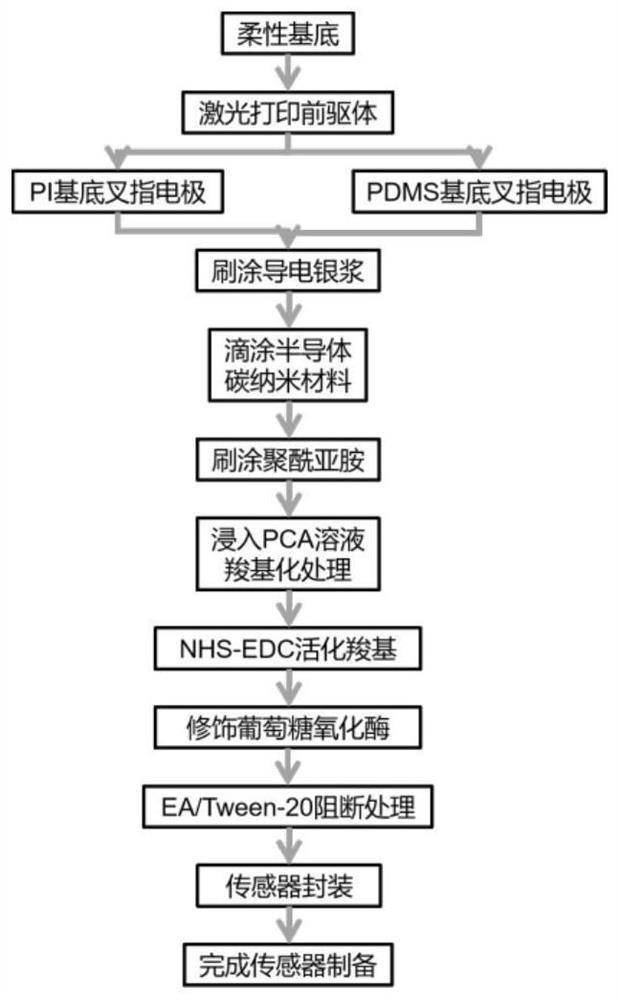

[0040] Such as Figure 1-3 Shown, the flexible glucose biosensor prepared by the present invention, its specific process is as follows:

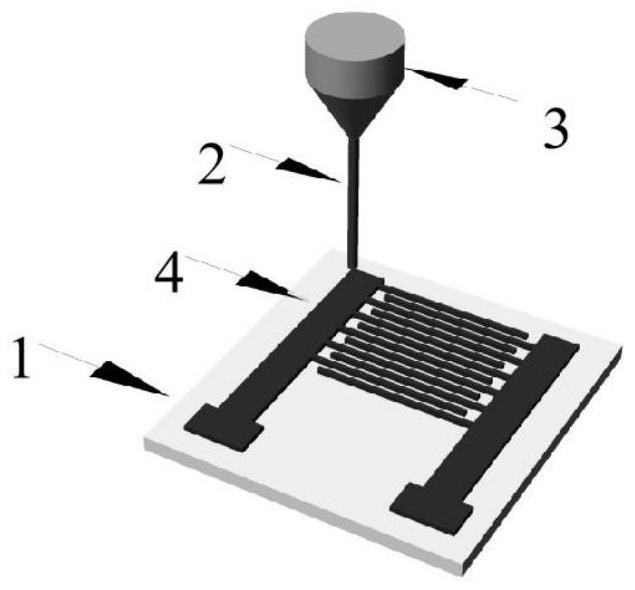

[0041] (1) Interdigital electrodes

[0042] The present invention utilizes laser direct writing technology to prepare interdigitated electrodes, wherein the flexible substrate 1 is PI with a thickness of 80 μm, the wavelength of the laser 2 used in this embodiment is 450nm, the power of the laser probe 3 is 5.5W, and the scanning speed of the laser is 4cm / s. Under this laser parameter, the laser induces the precursor to form a porous graphene electrode. The parameters of the generated interdigital electrodes 4 are that the interdigital spacing is 150 μm, and the single interdigital width is 450 μm.

[0043] In the above steps, the flexible precursor is PET, PC or PVC to prepare interdigital electrodes, which can also be applied to flexible glucose biosensors.

[0044] (2) Solid electrode wire

[0045] as right figure 1 As shown in (a)...

Embodiment 3

[0061] The difference from Example 2 is that in step (1), the flexible substrate 1 is PDMS, and interdigital electrodes are prepared by PDMS transfer printing.

[0062] In the present embodiment, the thickness of the PDMS film 12 is 450 μm, such as Figure 4 As shown, the preparation process includes the following steps:

[0063] (1) Use PI substrate 1 as the precursor of laser-induced technology, with a thickness of 80 μm, and use laser 2 with a wavelength of 450 nm, laser probe 3 with a power of 4 W, and a laser scanning speed of 1 cm / s to induce porous graphene electrode. The parameters of the generated interdigital electrodes 4 are that the interdigital spacing is 50 μm, and the single interdigital width is 200 μm. Place the prepared interdigital electrode 4 facing up in the Petri dish.

[0064] (2) Coating PDMS liquid on the interdigital electrodes 4, and then curing at high temperature to form a PDMS film 12 with a thickness of 450 μm, the curing temperature is 75° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com