High-toughness, high-strength and low-wet-expansion fiber cement external wall panel and preparation method thereof

A technology of fiber cement and exterior wall panels, applied in the field of building materials, can solve the problems of high toughness, high strength, low humidity expansion and weather resistance, etc., and achieve the effects of high water saturated flexural strength, high product cost performance, and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

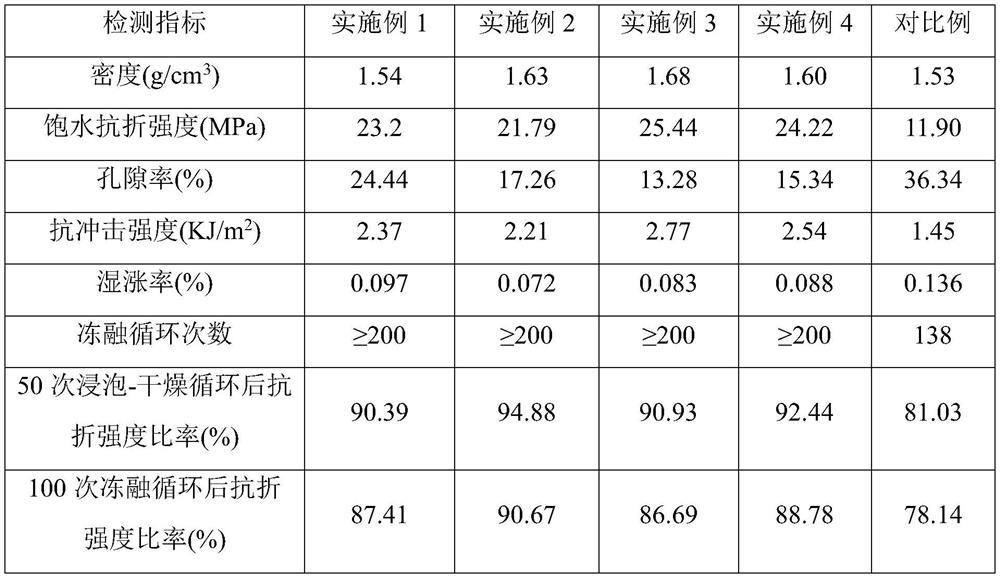

Examples

Embodiment 1

[0030] This embodiment provides a high-toughness, high-strength, low-swelling fiber cement exterior wallboard, including the following components in parts by weight: 29 parts of cement, 33 parts of quartz sand, 8 parts of quartz powder, 4 parts of micro-silica fume, powder 18 parts of coal ash, 14 parts of limestone powder, 1 part of aluminum hydroxide, 4 parts of mica powder, 3 parts of wollastonite, and 7 parts of pulp. Among them, cement is ordinary Portland cement; SiO in quartz sand 2 The content of SiO>90wt%, and the 200-mesh sieve of quartz sand is less than 1wt%; SiO in quartz powder 2 content > 98wt%, and the 400-mesh sieve balance of quartz powder is less than 1wt%; SiO in microsilica powder 2content>85wt%, and the specific surface area of silica fume is 15000-35000m 2 / kg; SiO in fly ash 2 content>50wt%, Al 2 o 3 content>27wt%, and fly ash 325 mesh sieve residue is less than 12wt%; CaCO in limestone powder 3 content>98wt%, and limestone powder 800 mesh sieve...

Embodiment 2

[0038] This embodiment provides a high-toughness, high-strength, low-swelling fiber cement exterior wallboard, including the following components in parts by weight: 37 parts of cement, 35 parts of quartz sand, 5 parts of quartz powder, 5 parts of micro-silica fume, powder 14 parts of coal ash, 14 parts of limestone powder, 2 parts of aluminum hydroxide, 2 parts of mica powder, 1 part of wollastonite, 6 parts of pulp. Wherein, wherein, cement is ordinary portland cement; SiO in quartz sand 2 content > 90wt%, and the 200-mesh sieve balance of quartz sand is less than 1wt%; SiO in quartz powder 2 content > 98wt%, and the 400-mesh sieve balance of quartz powder is less than 1wt%; SiO in microsilica powder 2 content > 85wt%, and the specific surface area of silica fume is 15000-35000m 2 / kg; SiO in fly ash 2 content>50wt%, Al 2 o 3 content>27wt%, and fly ash 325 mesh sieve balance is less than 12wt%; CaCO in limestone powder 3 content>98wt%, and limestone powder 800 mesh s...

Embodiment 3

[0041] This embodiment provides a high-toughness, high-strength, low-swelling fiber cement exterior wallboard, including the following components in parts by weight: 30 parts of cement, 18 parts of quartz sand, 13 parts of quartz powder, 3 parts of micro-silica fume, powder 21 parts of coal ash, 14 parts of limestone powder, 3 parts of aluminum hydroxide, 3 parts of mica powder, 5 parts of wollastonite, and 9 parts of pulp. Among them, cement is ordinary Portland cement; SiO in quartz sand 2 The content of SiO>90wt%, and the 200-mesh sieve of quartz sand is less than 1wt%; SiO in quartz powder 2 content>98wt%, and the 400-mesh sieve balance of quartz powder is less than 1wt%; SiO in silica fume 2 content>85wt%, and the specific surface area of silica fume is 15000-35000m 2 / kg; SiO in fly ash 2 content>50wt%, Al 2 o 3 content>27wt%, and fly ash 325 mesh sieve balance is less than 12wt%; CaCO in limestone powder 3 content>98wt%, and limestone powder 800 mesh sieve balan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com