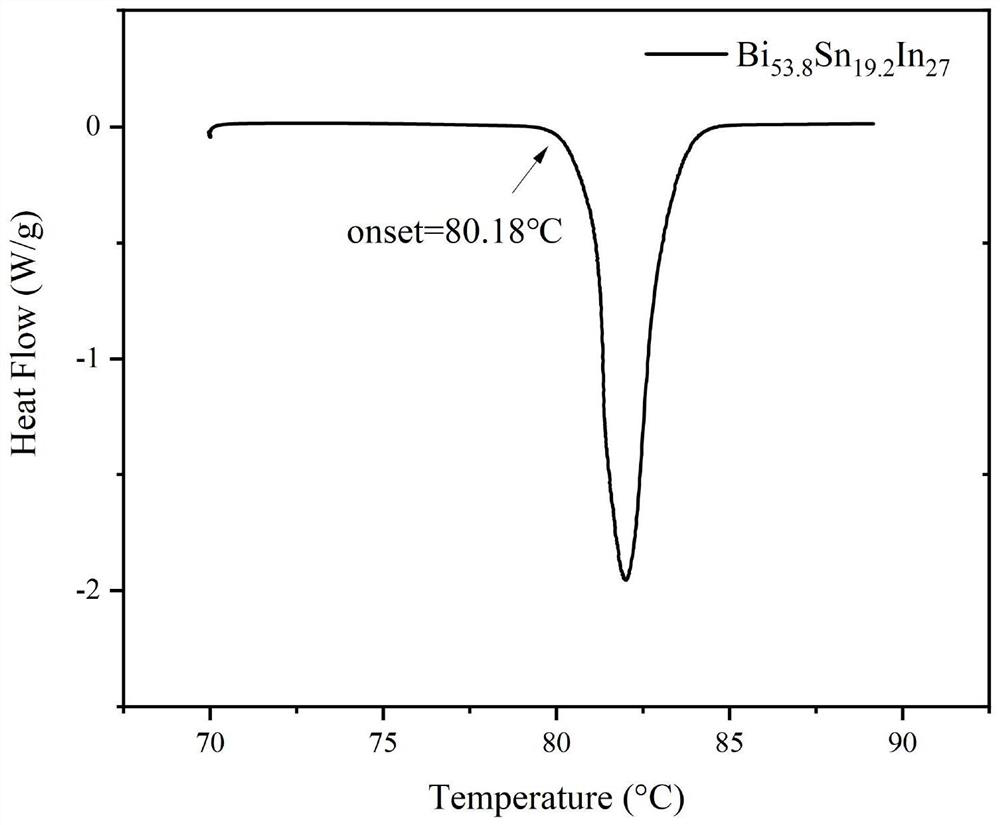

Bismuth-based liquid metal with melting point lower than 50 DEG C and preparation method thereof

A liquid metal, bismuth-based technology is applied in the field of bismuth-based liquid metal and its preparation, which can solve the problems of unreachable, and achieve the effects of clear components and simple experiments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the liquid metal in following embodiment, comparative example, comprises the following steps:

[0037] (1) Weigh a suitable pure metal sample, the selected pure metal sample purity is 99.99%, then polish the surface oxide layer with 800# sandpaper, then it is packed into the sample bag filled with dehydrated alcohol, Put it into Jiemeng JP-010S ultrasonic cleaning machine for cleaning. The cleaned samples were dried and then put into reaction vessels in the order of cadmium, zinc, bismuth, lead and indium.

[0038] (2) Fill high-purity nitrogen into the reaction vessel (a quartz test tube with an inner diameter of 9 mm, an outer diameter of 12 mm, and a height of 29 cm), and use a sealing machine [Partulab MRVS-1002; purchased from Bailibo Technology (China)] to vacuum seal tube processing. The specific operation is: put the test tube containing the sample into the tube sealing machine, turn on the mechanical pump, then turn on the vacuum pum...

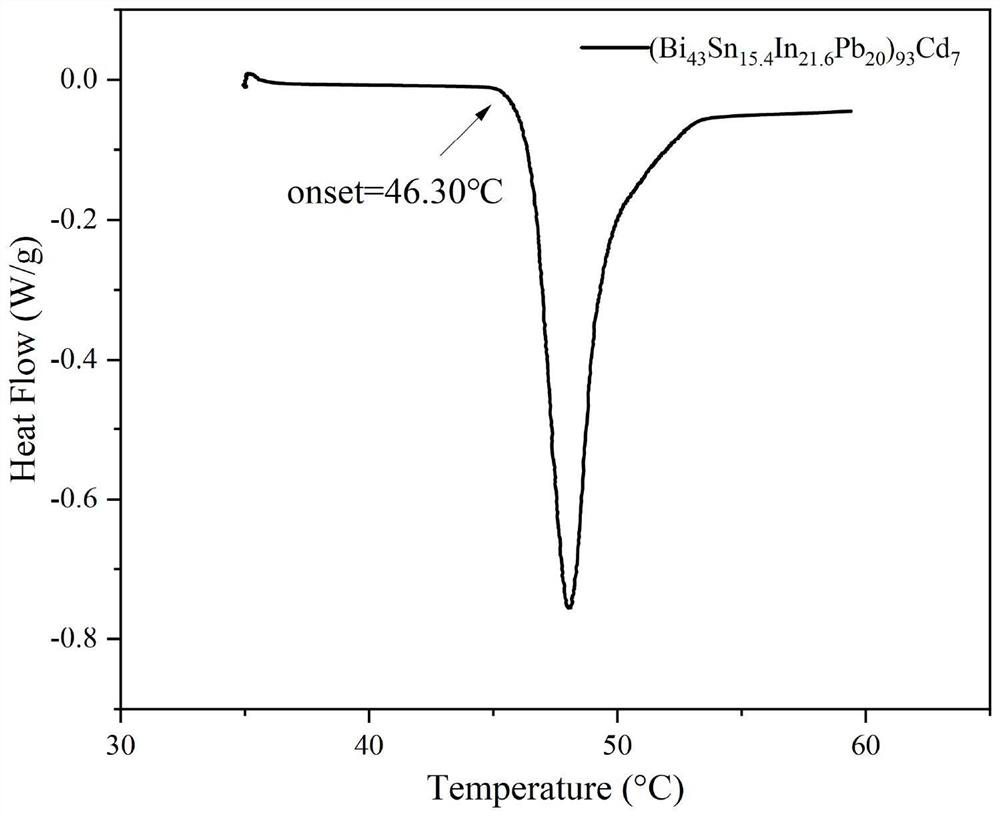

Embodiment 1

[0043] Liquid metal is (Bi 43 sn 15.4 In 21.6 Pb 20 ) 93 Cd 7 (mass parts: 40.0 parts of bismuth, 20.1 parts of indium, 18.6 parts of lead, 14.3 parts of tin, 7 parts of cadmium), its preparation method comprises the following steps:

[0044] (1) Weigh a pure metal sample with a total mass of about 5g, then polish the surface oxide layer with 800# sandpaper, put it into a sample bag filled with absolute ethanol, and put it into an ultrasonic cleaner for cleaning. Dry and clean the samples, and then put them into the reaction vessel in the order of cadmium, zinc, bismuth, lead, and indium.

[0045] (2) Inert gas is filled into the reaction vessel (a quartz test tube with an inner diameter of 9mm, an outer diameter of 12mm, and a height of 29cm), and a tube sealing machine is used to vacuumize and seal the tube with a vacuum degree of 0.01Pa. Gas scrubbing was repeated at least 3 times, and high-purity nitrogen was filled after scrubbing to build a protective atmosphere; t...

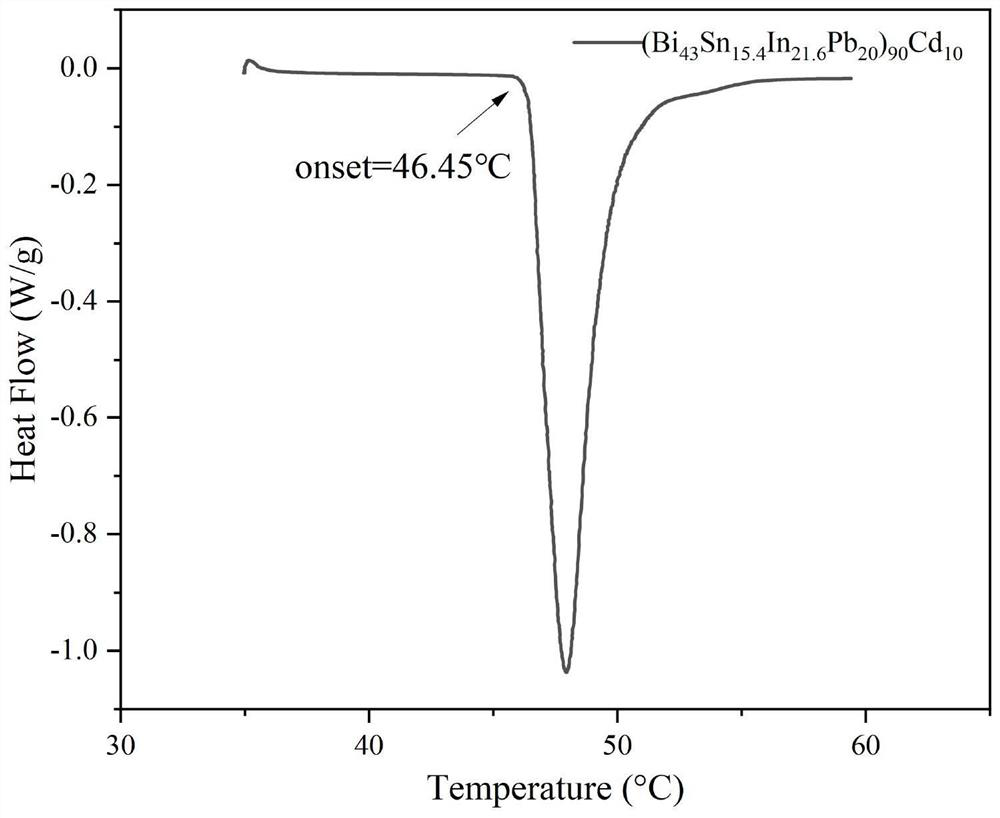

Embodiment 2

[0050] Liquid metal is (Bi 43 sn 15.4 In 21.6 Pb 20 ) 90 Cd 10 (mass parts: 38.7 parts of bismuth, 19.4 parts of indium, 18 parts of lead, 13.9 parts of tin, 10 parts of cadmium), its preparation method comprises the following steps:

[0051] (1) Weigh a pure metal sample with a total mass of about 5g, then polish the surface oxide layer with 800# sandpaper, put it into a sample bag filled with absolute ethanol, and put it into an ultrasonic cleaner for cleaning. Dry and clean the samples, and then put them into the reaction vessel in the order of cadmium, zinc, bismuth, lead, and indium.

[0052] (2) Inert gas is filled into the reaction vessel (a quartz test tube with an inner diameter of 9mm, an outer diameter of 12mm, and a height of 29cm), and a tube sealing machine is used to vacuumize and seal the tube with a vacuum degree of 0.01Pa. Gas scrubbing was repeated at least 3 times, and high-purity nitrogen was filled after scrubbing to build a protective atmosphere; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com