Treatment agent specially used for treating domestic waste leachate

A domestic garbage and treatment agent technology, applied in the direction of flocculation/sedimentation water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problem that the water quality is difficult to meet the national secondary discharge standard, and cannot provide convenience for subsequent treatment sections. CODcr low efficiency and other problems, to achieve the effect of good shear resistance of flocs, simple structure, and improved flocculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

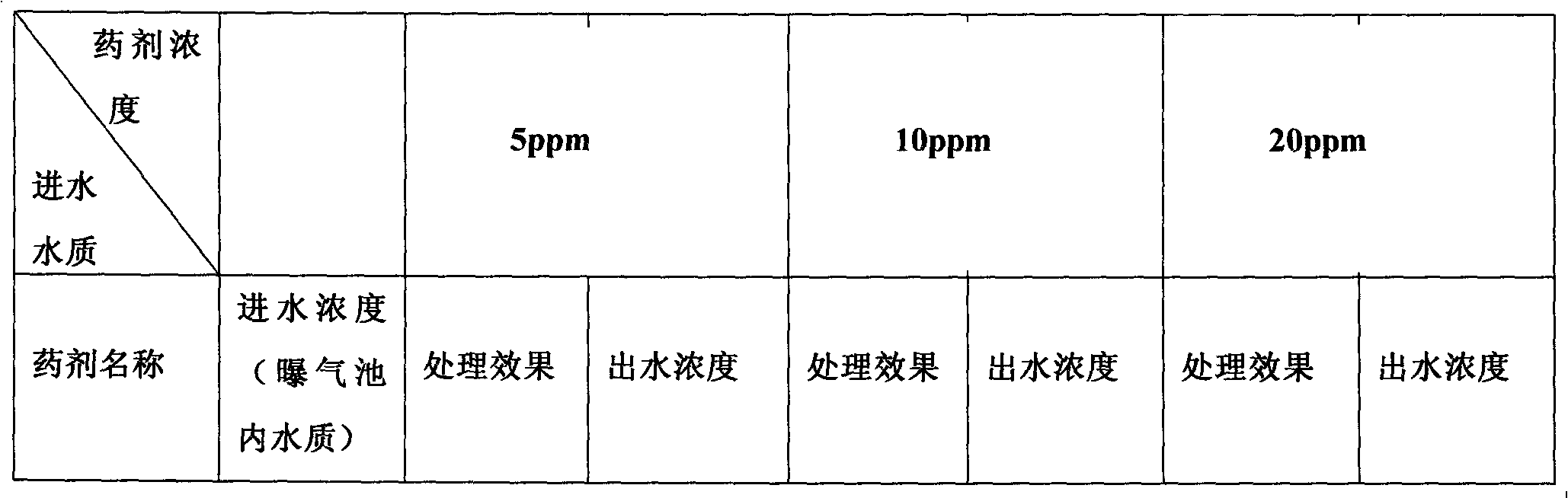

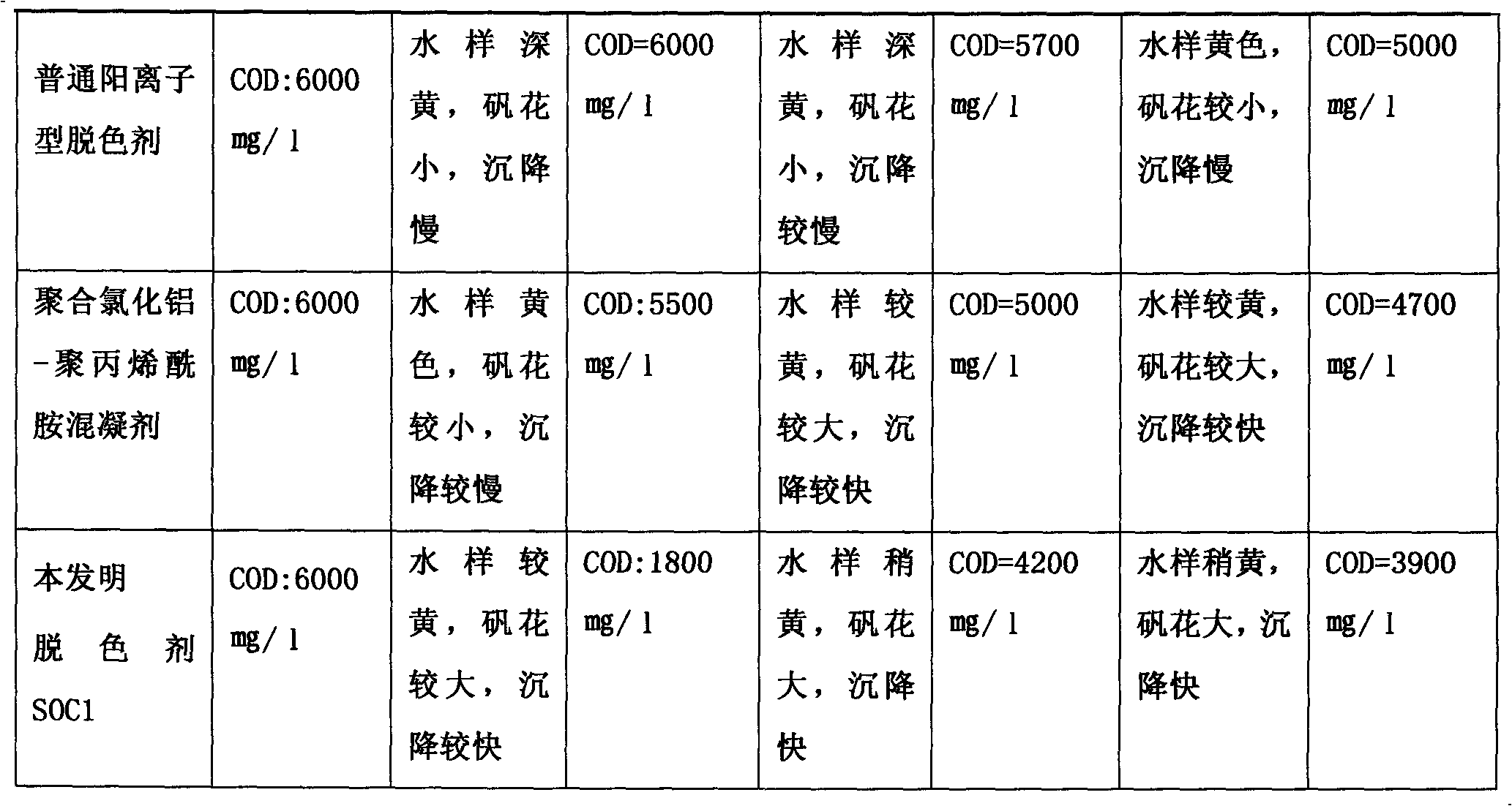

Examples

Embodiment 1

[0046] 1. The raw materials of each component are:

[0047] Polyaluminum ferric chloride (PAFC) 72kg;

[0048] Polydimethyldiallylammonium chloride (PDMDAAC) 28kg;

[0049] Tap water 88kg.

[0050] 2. Its preparation method is:

[0051] (1) Put polyaluminum ferric chloride (PAFC) dry powder with a mass fraction of 30.5% in a mixing kettle, add water to prepare the PAFC content in AL 2 o 3 The mass fraction is 8%-10%; the solution is 1%-2% iron oxide mass fraction.

[0052] (2) Stir the PAFC solution at room temperature -4°C-36°C, add a colloid with a characteristic viscosity of 1.0-4.7dL / g and a solid content of 20%-75% by mass fraction or (92±2)% Dry powder polydimethyldiallylammonium chloride (PDMDAAC). Make the mixed solution with AL 2 o 3 The calculated mass ratio of PAFC to PDMDAAC is 20.5:1-2.5:1.

[0053] (3) Stir the mixed solution at normal temperature until the PDMDAAC colloid or dry powder is completely dissolved to obtain a stable polyaluminum ferric chlor...

Embodiment 2

[0062] 1. The raw materials of each component are:

[0063] Polyaluminum ferric chloride (PAFC) 72kg;

[0064] Polydimethyldiallylammonium chloride (PDMDAAC) 28kg;

[0065] Polyquaternium 5kg;

[0066] Tap water 88kg.

[0067] The treatment agent 2 made from raw materials according to the above weight percentage is specially placed in the causticization tank to decolorize, flocculate and sterilize the causticized liquid.

[0068] 2. Its preparation method is:

[0069] (1) Put polyaluminum ferric chloride (PAFC) dry powder with a mass fraction of 30.5% in a mixing kettle, add water to prepare the PAFC content in AL 2 o 3 The mass fraction is 8%-10%; the solution is 1%-2% iron oxide mass fraction.

[0070] (2) Stir the PAFC solution at room temperature -4°C-36°C, add a colloid with a characteristic viscosity of 1.0-4.7dL / g and a solid content of 20%-75% by mass fraction or (92±2)% Dry powder polydimethyldiallylammonium chloride (PDMDAAC). Make the mixed solution with AL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com