Preparation method and application of lignin modified titanium carbide oil-water separation material

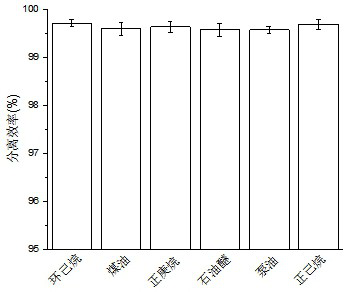

A technology for oil-water separation and lignin, which is applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of weak anti-oxidation ability and easy to be oxidized, and achieve fast water absorption rate, good stability and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of lignin modified titanium carbide oil-water separation material comprises the following steps:

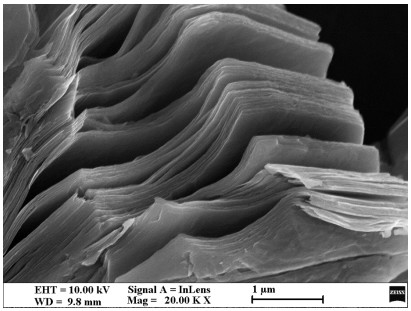

[0029] (1) Select 1g of Ti 3 AlC 2 The powder was immersed in 20 mL of HF solution at 40 °C for 72 h with magnetic stirring. The resulting suspension was centrifuged and washed with deionized water until the pH of the supernatant reached 7.0; the obtained precipitate was dried in a vacuum oven at 60 °C for 24 h to obtain titanium carbide Ti 3 C 2 T x powder.

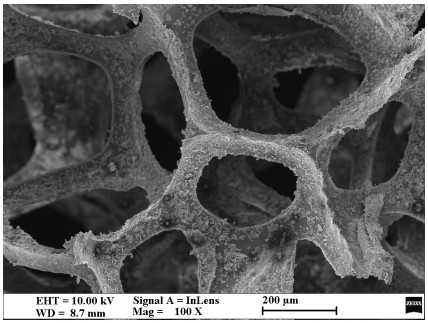

[0030] (2) Weigh 100mg Ti 3 C 2 T x Dispersed into 100mL deionized water to prepare Ti 3 C 2 T x Dispersion solution, add 50mg of enzymatic lignin (purchased from Shandong Changshou Password Biotechnology Co., Ltd.) and ammonia solution under stirring conditions, and Ti 3 C 2 T x Adjust the pH value of the dispersion to 8.0, then ultrasonically (100W) for 5 minutes and continue magnetic stirring for 6 hours to obtain a brownish-yellow mixture; the brownish-yellow mixture was centri...

Embodiment 2

[0034] The preparation method of lignin modified titanium carbide oil-water separation material comprises the following steps:

[0035] (1) Select 1g of Ti 3 AlC 2 The powder was immersed in 20 mL of HF solution at 40 °C for 72 h with magnetic stirring. The resulting suspension was centrifuged and washed with deionized water until the pH of the supernatant reached 7.0. The obtained precipitate was dried in a vacuum oven at 60 °C for 24 h to obtain titanium carbide Ti 3 C 2 T x powder.

[0036] (2) Weigh 100mg Ti 3 C 2 T x Disperse in 100mL of deionized water, add 100mg of enzymatic lignin and sodium hydroxide aqueous solution in sequence under stirring, adjust the pH value of the dispersion to 9.0, then ultrasonic (100W) for 5min and then magnetically stir for 6h to obtain a brown-yellow mixture; The brown-yellow mixture was repeatedly centrifuged and washed until the pH of the supernatant was 7.0, and the resulting product was freeze-dried for 24 hours and then taken...

Embodiment 3

[0039] The preparation method of lignin modified titanium carbide oil-water separation material comprises the following steps:

[0040](1) Select 1g of Ti 3 AlC 2 The powder was immersed in about 20 mL of HF solution at 40 °C and stirred with a magnetic stirring bar for 72 h. The resulting suspension was then centrifuged and washed with deionized water until the pH of the supernatant reached 7.0. The obtained precipitate was dried in a vacuum oven at 60 °C for 24 h to obtain titanium carbide Ti 3 C 2 T x powder.

[0041] (2) Weigh 100mg Ti 3 C 2 T x Add 100mL of deionized water, add 20mg of enzymatic lignin and potassium hydroxide aqueous solution sequentially under stirring conditions, adjust the pH value to 11.0, then ultrasonic (100W) for 5min and then magnetically stir for 6h to obtain a brown-yellow mixture. The brown-yellow mixture was centrifuged and washed repeatedly until the pH of the supernatant was 7.0, and the resulting product was freeze-dried for 24 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com