High-wear-resistance wiredrawing non-woven fabric grinding material, preparation method and application thereof

An abrasive material, high wear-resistant technology, used in abrasives, abrasive tools, textiles and papermaking, etc., can solve the problems of insufficient heat dissipation performance of nylon wheels, poor local drawing effect, scratched workpieces, etc., to achieve high flexibility, The effect of high porosity, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0021] The high wear-resistant type wire drawing non-woven abrasive material of the embodiment comprises a base material and a slurry, wherein the base material is formed of a three-dimensional network structure interlaced by three kinds of nylon fibers with different deniers and higher crimps, and the nylon fibers The deniers are 15D, 40D, and 110D respectively, and the dosage ratio is controlled at 10-30% for 15D, 20-40% for 40D, and 50-70% for 110D. The crimp of nylon fiber is 7-13 crimps in 5cm fiber length.

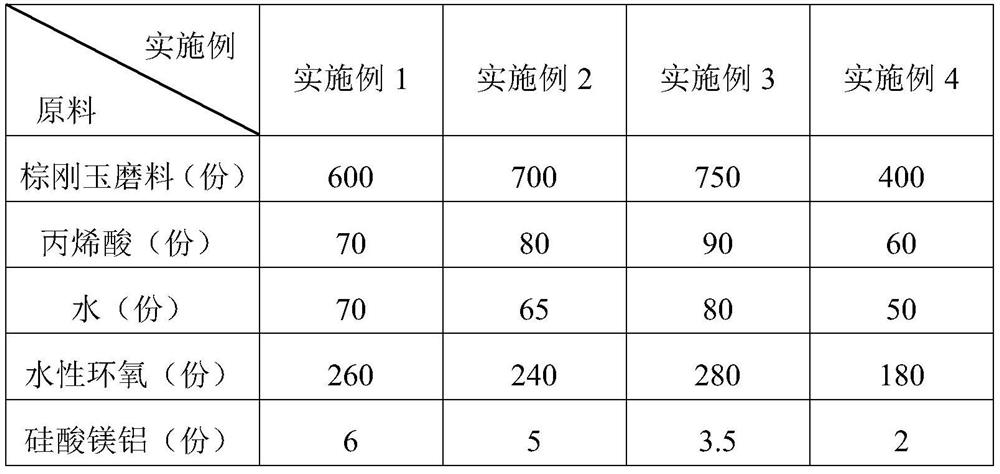

[0022] The wear-resistant slurry in Examples 1-3 includes the following components by weight:

[0023]

[0024] Acrylic acts as a modified adhesive bond, giving the adhesive some of the toughness of acrylic.

[0025] The water-based epoxy used in the embodiment of the present invention was purchased from Shandong Shengquan New Material Co., Ltd.

[0026] Preparation process of grinding material:

[0027] S1. First of all, for the treatment of the base material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com