Open-cell polyurethane negative poisson ratio foam material and preparation method thereof

A technology of polyurethane foam and negative Poisson's ratio, applied in coating and other directions, can solve problems such as uneven structure of inner and outer layers, and achieve the effect of avoiding uneven structure of inner and outer layers of materials, broad market prospects and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

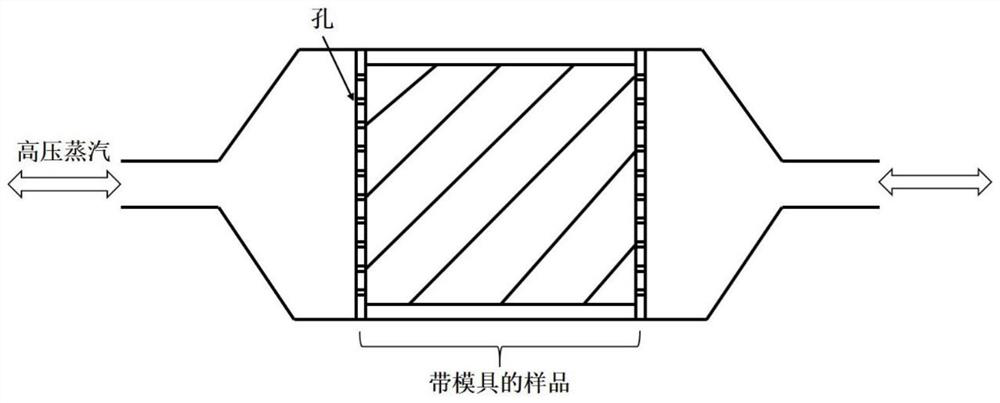

[0026] The invention provides a method for preparing an open-cell polyurethane negative Poisson's ratio foam material, comprising the following steps:

[0027] The open-cell polyurethane foam is sequentially compressed, pressurized saturated water vapor is heated and cooled to shape, and the open-cell polyurethane negative Poisson's ratio foam material is obtained.

[0028] In the preparation method provided by the present invention, as long as the open-cell polyurethane foam satisfies that the cells have an open-cell structure and Poisson's ratio ≥ 0, there is no special limitation; the open-cell polyurethane foam can be polyether polyurethane foam , can also be a polyester polyurethane foam, preferably a polyether polyurethane foam; the open cell structure of the open cell polyurethane foam can be a full open cell structure, and can also be a semi open cell structure; the open cell polyurethane foam The density is preferably 10-300kg / m 3 , more preferably 20-120kg / m 3 , sp...

Embodiment 1

[0054] Set the density to 10kg / m 3 The open-cell polyurethane foam (self-made, formula shown in Table 1, Poisson’s ratio is 0.5, size is 16cm×10cm×7cm) is subjected to triaxial compression treatment, the compression ratio is 5.0 times, and the size after compression is 9.37cm×5.85cm×4.09 cm, put the compressed foam together with the compression mold in the water vapor penetrating heating device, use 170°C high-pressure saturated steam to heat through one side for 5 seconds, and then take it out together with the compression mold and cool it to room temperature. After testing, the Poisson's ratio of the surface layer and the core layer of the foam material is uniform, and the Poisson's ratio is -1.0.

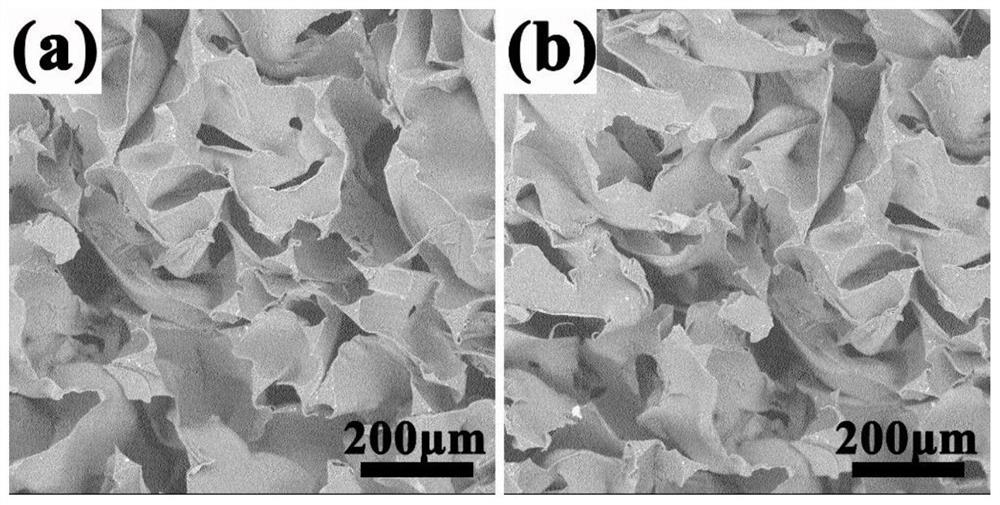

[0055] figure 2 It is a scanning electron microscope image of the foam material provided by Example 1 of the present invention, Figure a is a scanning electron microscope image of a foam core layer, and Figure b is a scanning electron microscope image of a foam surface layer. ...

Embodiment 2

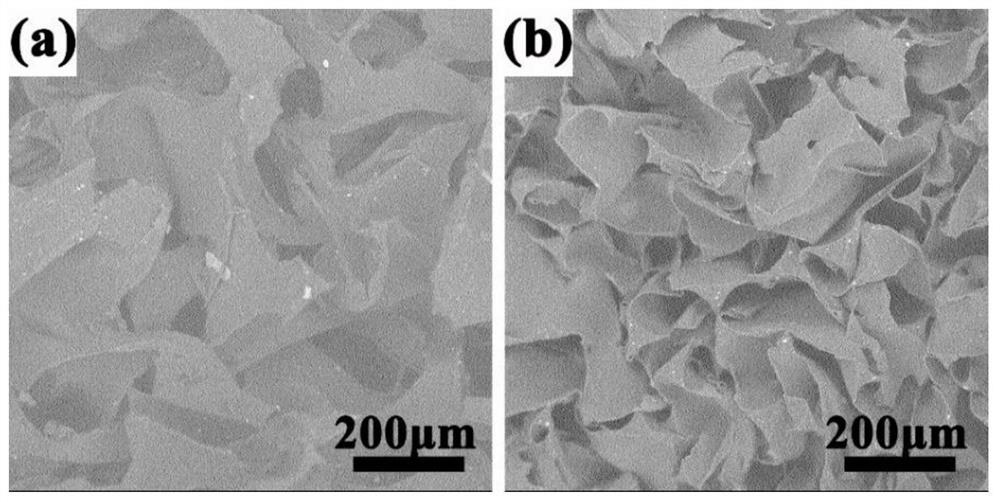

[0061] Set the density to 23kg / m 3 The open-cell polyurethane foam (Dongguan Hengying Sponge Products Co., Ltd., Poisson’s ratio is 0.4, the size is 16cm×10cm×7cm) is subjected to triaxial compression treatment, the compression ratio is 3.4 times, and the compressed size is 10.65cm×6.65cm ×4.65cm, put the compressed foam together with the compression mold in the steam penetrating heating device, and use 165°C high-pressure saturated water vapor to repeatedly penetrate and heat both sides for 60s (specifically: after the left side penetrates for 30s, switch to the right Side penetration 30s), and then take out together with the compression mold and cool to room temperature. After testing, the Poisson's ratio of the surface layer and the core layer of the foam material is uniform, and the Poisson's ratio is -0.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com