Ampelopsis grossedentata tea agricultural waste plant dye and application of preparation method thereof in cloth dyeing

A technology of agricultural waste and plant dyes, which is applied to the application field of berry tea agricultural waste plant dyes and its preparation method in dyeing cloth, which can solve the problems of aging branches, reducing the utilization value of berry tea resources, and poor taste. , to achieve the effect of reducing environmental pollution, increasing farmers' income, and improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0046] The preparation of preparation example 1 dyestuff

[0047] (1) Mixing of plant raw materials:

[0048] Take 450 g of the crushed berry tea in the processing process or 450 g of berry tea stems and leaves trimmed during planting, and pulverize through a 40-mesh sieve; take 50 g of Polygonum hydrangea stems and leaves, pulverize them through a 40-mesh sieve, and mix the two to obtain raspberry tea dyeing raw material powder;

[0049] (2) Enzymolysis:

[0050] Adjust deionized water to pH 6.0 with 10% (w / v) HCl, heat to 50°C, add cellulase and pectinase, and prepare to contain 0.5% (w / v) cellulase, pectinase 0.2% (w / v) compound enzyme solution;

[0051] Take 1000ml of the compound enzyme solution and add it to the raw material powder of raspberry tea dyeing, and keep it at 40°C for 2 hours for enzymatic hydrolysis;

[0052] (3) alcohol extraction:

[0053] Add 5L of 50% (v / v) ethanol aqueous solution to the mixed solution obtained in step (2), ultrasonically extract fo...

preparation example 2

[0058] The preparation of preparation example 2 dyestuffs

[0059] (1) Mixing of plant raw materials:

[0060] Take 450g of the crushed raspberry tea in the processing process or 450g of raspberry tea stems and leaves trimmed during planting, and pulverize through a 60-mesh sieve; take 50g of Polygonum hydrangea stems and leaves, pulverize them through a 60-mesh sieve, and mix the two to obtain raspberry tea dyeing raw material powder;

[0061] (2) Enzymolysis:

[0062] Adjust deionized water to pH 4.0 with 10% (w / v) HCl, heat to 40°C, add cellulase and pectinase, and prepare to contain 1.5% (w / v) cellulase, pectinase 0.8% (w / v) compound enzyme solution;

[0063] Take 1000ml of the compound enzyme solution and add it to the raw material powder of raspberry tea dyeing, and keep it at 50°C for 1.5h;

[0064] (3) alcohol extraction:

[0065] Add 5L of 70% (v / v) ethanol aqueous solution to the mixed solution obtained in step (2), ultrasonically extract for 30min, filter the ex...

Embodiment 1

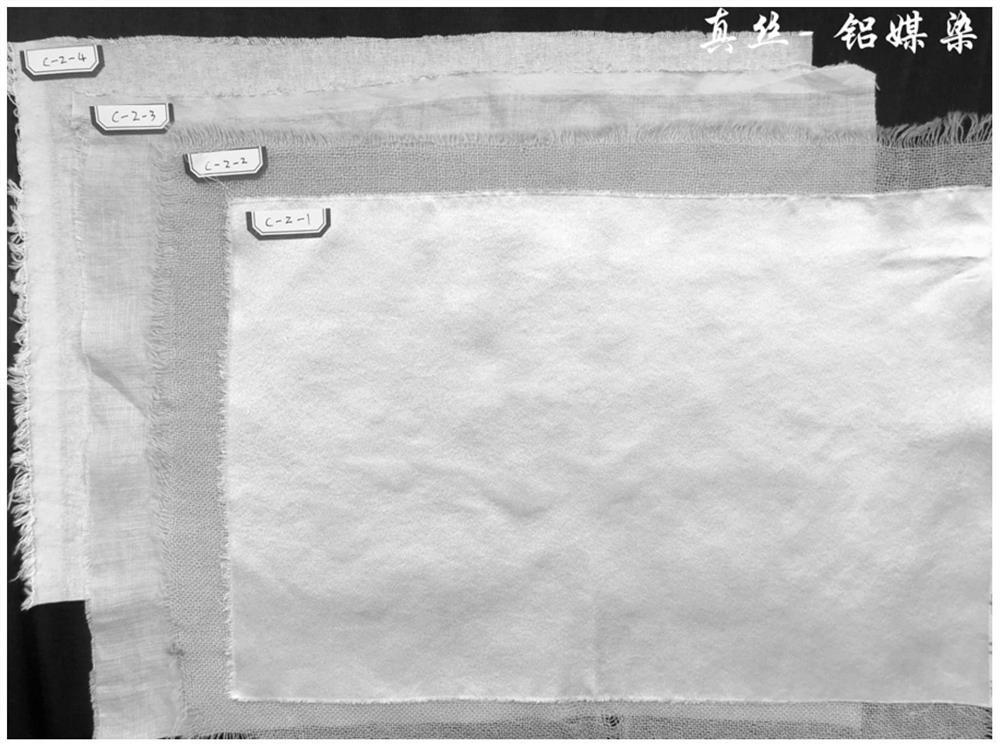

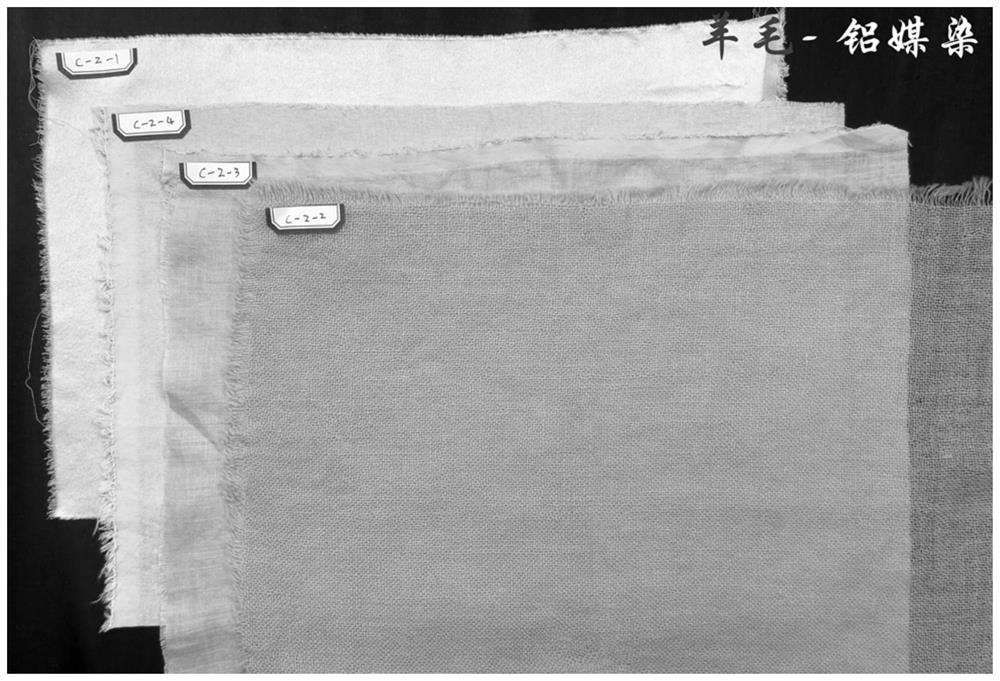

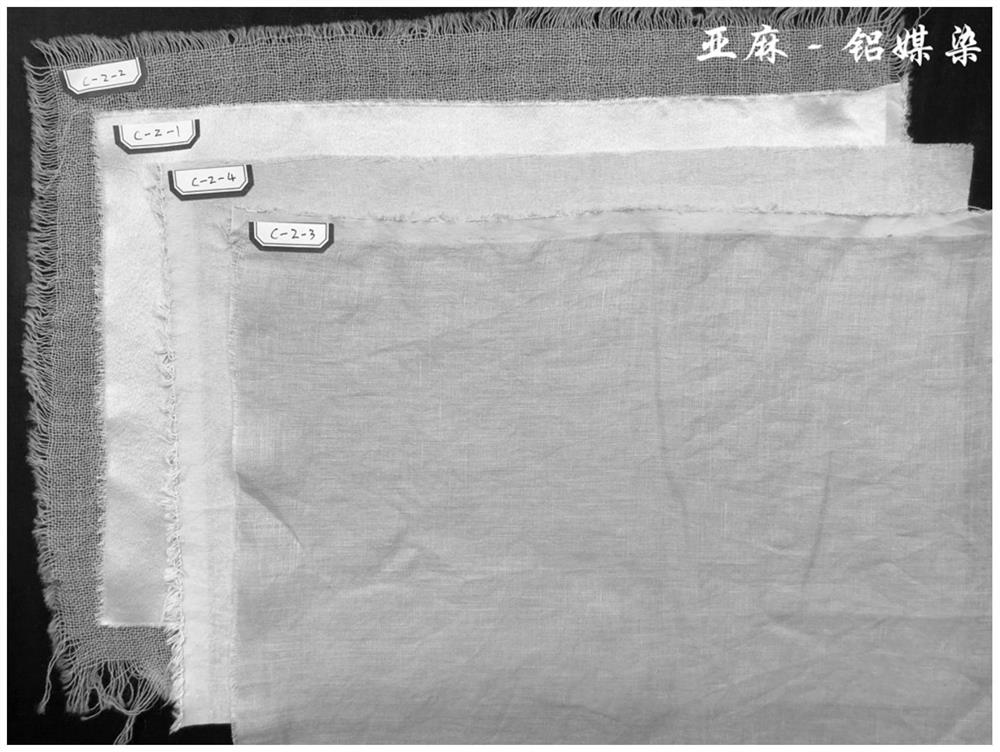

[0070] Embodiment 1 alum is the same bath mordant of mordant (aluminum mordant dyeing)

[0071] Take 50ml of the liquid raspberry tea dye obtained in Preparation Example 1, add 1L of water, and heat to 60°C while stirring to fully dissolve it to form a raspberry tea dye solution, put it in a dyeing vat, add 4g of alum as a mordant in the dyeing vat; take the dye to be dyed The fabric (the fabric is soaked with water in advance, dried or wrung out) is placed in the dyeing solution, and dyed at 60°C for 10 minutes. During this period, the fabric is continuously adjusted to make the dyeing uniform. After 10 minutes, take it out, squeeze out excess water, dry it slightly, and wash it fully with water. Wash away the floating color and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com