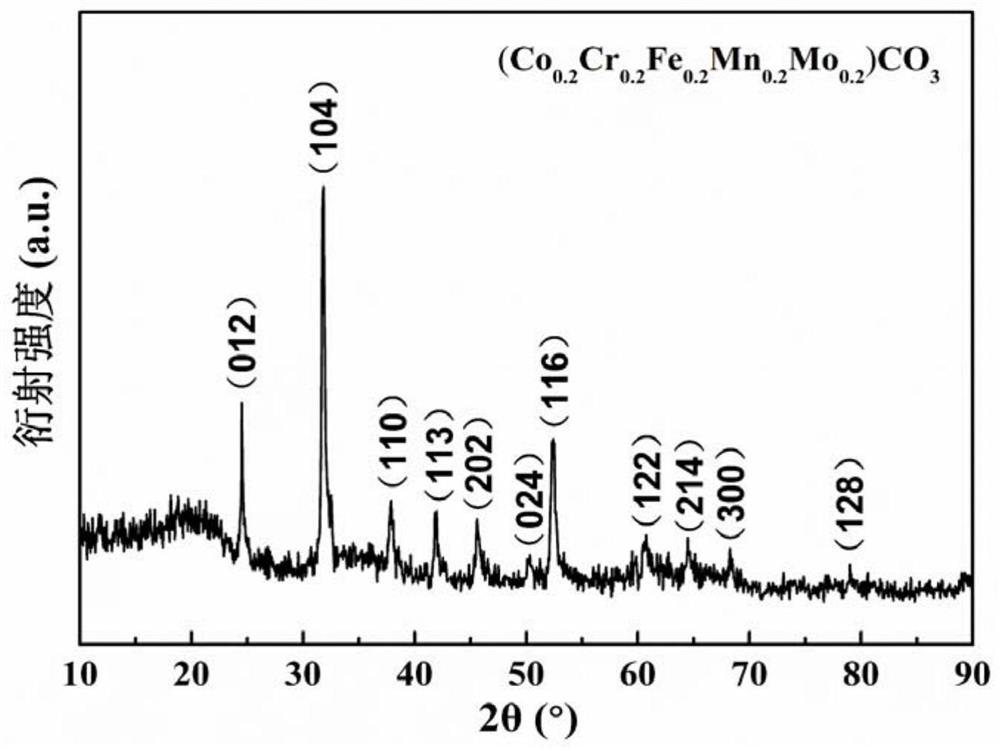

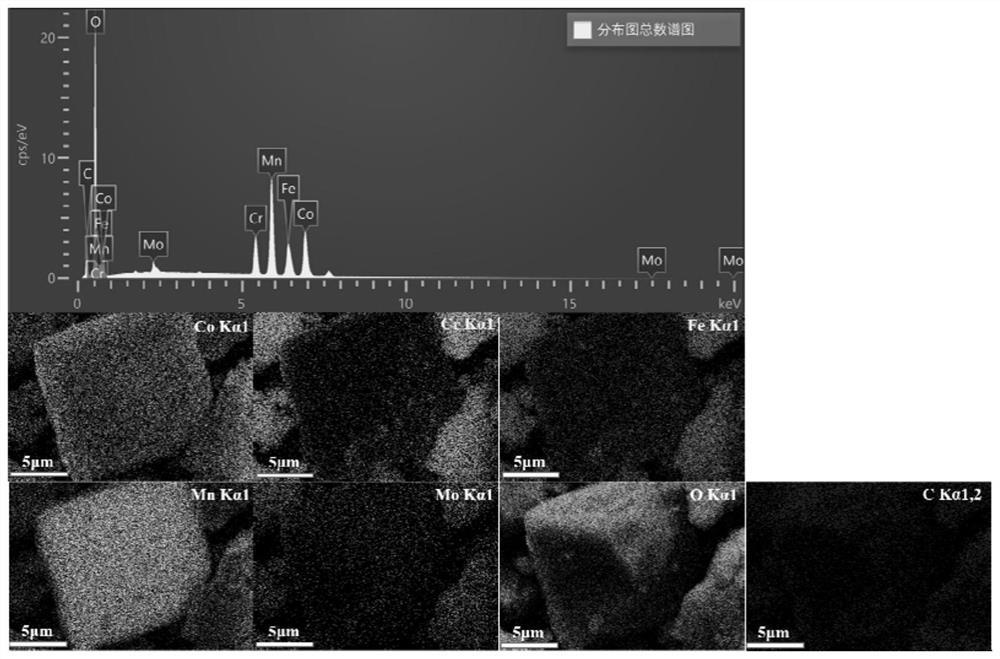

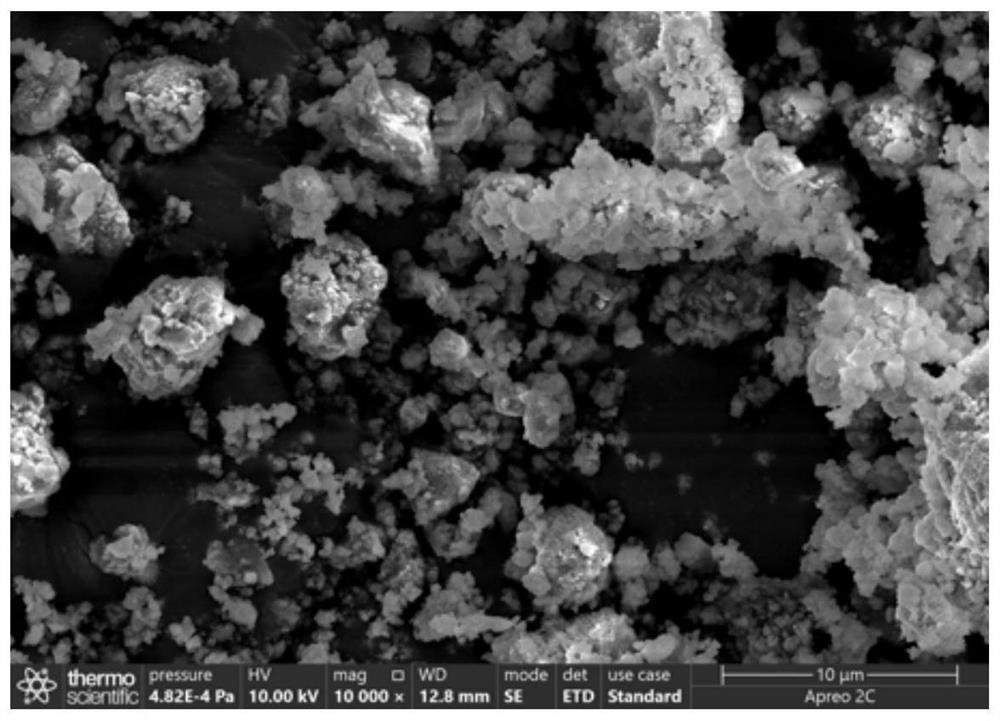

A kind of high entropy carbonate electrocatalyst and preparation method thereof

An electrocatalyst and carbonate technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of high price and poor catalytic activity, achieve low production cost, increase the density of states, and facilitate market promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of high entropy carbonate electrocatalyst, its preparation method comprises the following steps:

[0031] (1) Inorganic salts of five metals including cobalt, chromium, iron, manganese and molybdenum are used as raw materials, and the molar ratio of the five elements of cobalt, chromium, iron, manganese and molybdenum is 1:1:1:1:1, respectively Weigh 0.498g Co(CH 3 COO) 2 4H 2 O, 0.8gCr(NO 3 ) 3 9H 2 O, 0.808gFe(NO 3 ) 3 9H 2 O, 0.396g MnCl 2 4H 2 O and 0.353g (NH 4 ) 6 Mo 7 o 24 4H 2 O, be dissolved in 80mL deionized water to form a mixed solution of inorganic salts; 6.6g urea (CO(NH 2 ) 2 ) was dissolved in 30mL deionized water to obtain a precipitant solution, and then the precipitant solution was added to the inorganic salt mixed solution under stirring conditions, and after stirring for 1 hour, a reaction solution was obtained;

[0032] (2) Pour the reaction solution in step (1) into a closed reaction kettle, and conduct a hydrothermal react...

Embodiment 2

[0035] A kind of high entropy carbonate electrocatalyst, its preparation method comprises the following steps:

[0036](1) Inorganic salts of five metals of cobalt, chromium, iron, manganese and molybdenum are used as raw materials, and the molar ratio of the five elements of cobalt, chromium, iron, manganese and molybdenum is 1:3:2:3:1, respectively Weigh 0.291g Co(NO 3 ) 2 ·6H 2 O, 1.2gCr(NO 3 ) 3 9H 2 O, 0.541gFeCl 3 ·6H 2 O, 0.169g MnSO 4 ·H 2 O and 1.236g (NH 4 ) 6 Mo 7 o 24 4H 2 O, dissolved in 80mL deionized water to form a mixed solution of inorganic salts; 7.9g ammonium bicarbonate (NH 4 HCO 3 ) was dissolved in 30mL deionized water to obtain a precipitant solution, and then the precipitant solution was added to the inorganic salt mixed solution under stirring conditions, and after stirring for 1.5h, a reaction solution was obtained;

[0037] (2) Pour the reaction solution in step (1) into a closed reaction kettle, and conduct a hydrothermal reaction a...

Embodiment 3

[0040] A kind of high entropy carbonate electrocatalyst, its preparation method comprises the following steps:

[0041] (1) Inorganic salts of five metals of cobalt, chromium, iron, manganese, and molybdenum are used as raw materials, and the molar ratio of the five elements of cobalt, chromium, iron, manganese, and molybdenum is 2:1:3:2:2, respectively Weigh 0.563g CoSO 4 ·7H 2 O, 0.267gCrCl 3 ·6H 2 O, 1.212g Fe(NO 3 ) 3 9H 2 O, 0.574g Mn(NO 3 ) 2 ·6H 2 O and 2.472g (NH 4 ) 6 Mo 7 o 24 4H 2 O, be dissolved in 80mL deionized water to form a mixed solution of inorganic salts; 9.6g ammonium carbonate ((NH 4 ) 2 CO 3 ) was dissolved in 30mL deionized water to obtain a precipitant solution, and then the precipitant solution was added to the inorganic salt mixed solution under stirring conditions, and after stirring for 2 hours, a reaction solution was obtained;

[0042] (2) Pour the reaction solution in step (1) into a closed reaction kettle, and conduct a hydroth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com