A foam nickel load fe 2 o 3 @ni 3 s 2 Preparation method of composite structure oer electrocatalyst

An electrocatalyst and composite structure technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problem of not providing high catalytic activity, and achieve the effect of good industrial application prospects, excellent electrocatalytic performance, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] S1 nickel foam substrate pretreatment: cut the metal foam nickel (NF) substrate into a rectangle of 1.0cm×4.0cm, put it in 1.0M hydrochloric acid, ultrasonically treat it for 10min, and wash it with ultrapure water three times to remove Hydrochloric acid, finally washed with absolute ethanol, and dried in a vacuum oven after cleaning to obtain a pretreated foam nickel substrate;

[0022] Preparation of Ni by S2 3 S 2 / NF precursor: Measure 16ml of anhydrous ethanol and 16ml of anhydrous ethylenediamine respectively, add them into a beaker, stir magnetically for 10min to make the anhydrous ethanol and anhydrous ethylenediamine evenly mixed, then add 2mmol of sublimation sulfur, continue magnetic stirring 10min, so that the sublimation sulfur is fully dissolved, after stirring, the mixed solution and the pretreated foam nickel substrate prepared in step S1 are transferred into 50ml polytetrafluoroethylene lining, placed in the reaction kettle and packaged, the reaction k...

Embodiment 2

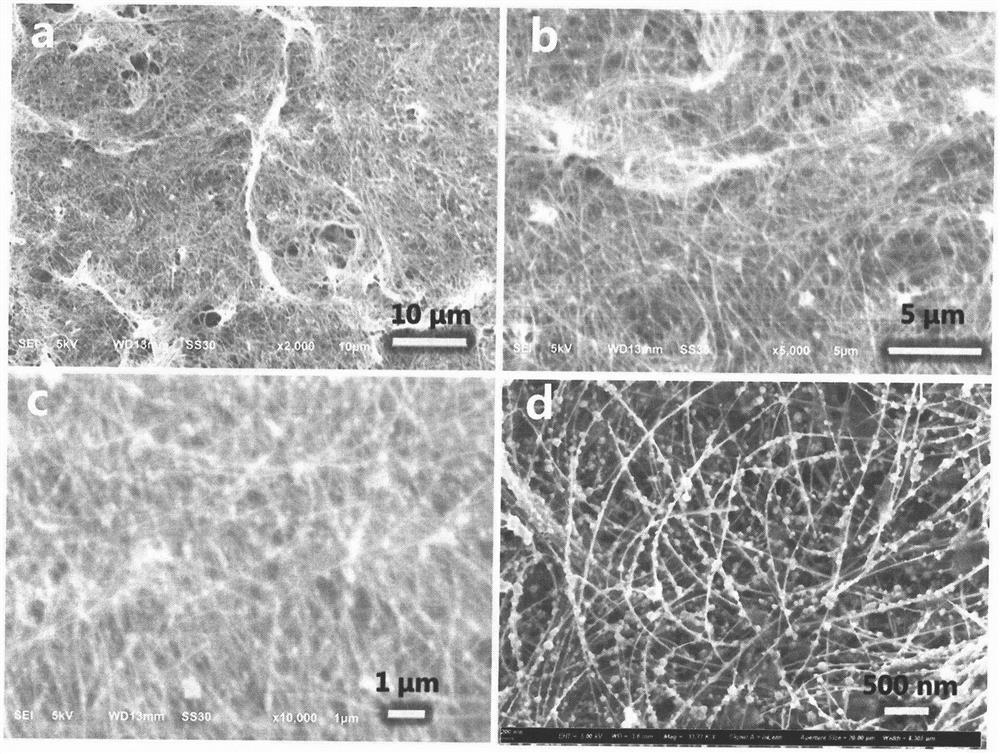

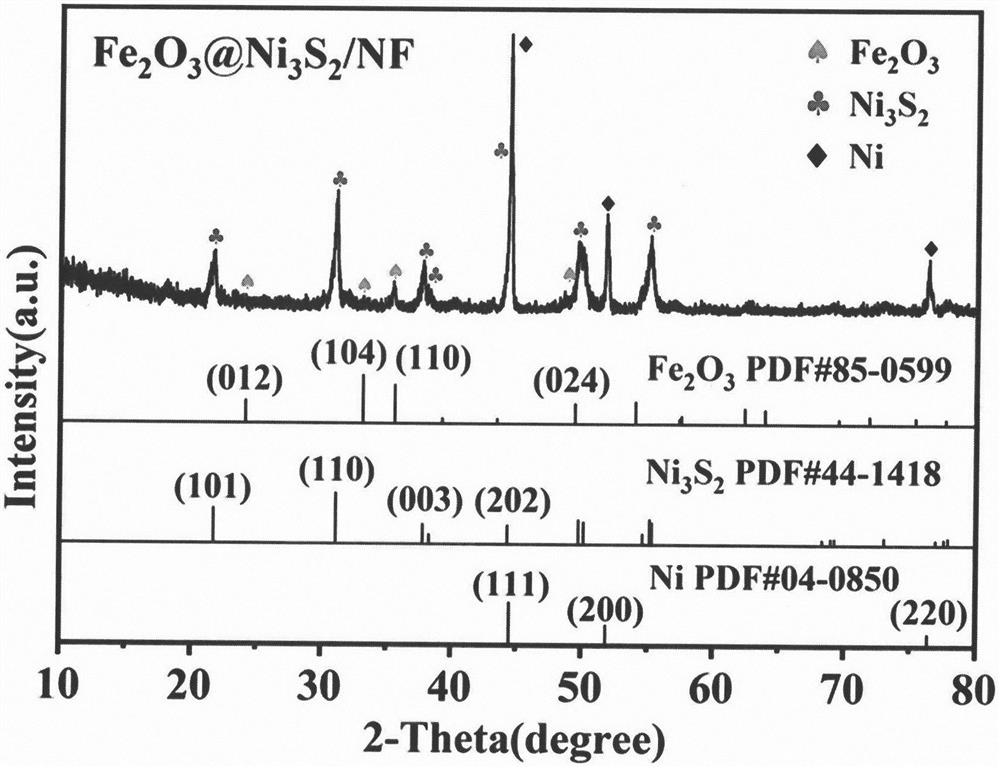

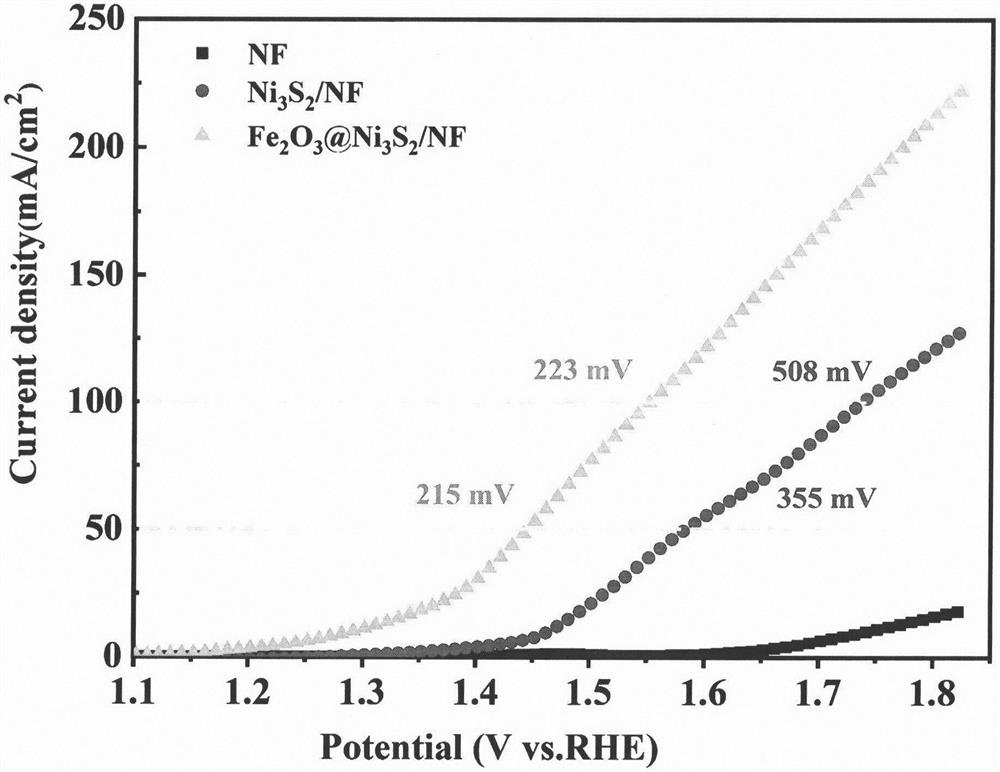

[0028] Figure 4 Fe prepared for Example 2 2 O 3 @Ni 3 S 2 SEM images and comparison of catalytic performance of / NF electrode materials. To study Fe 2+ The effect of the introduction amount on the OER catalytic performance and morphology of the material. Four different Fe 2+ Add molar amounts, respectively 0.2 mmol, 0.4 mmol, 0.6 mmol, 0.8 mmol, Figure 4 (a-c) show the SEM pictures of the samples at the first three molar amounts. Figure (a) shows that Fe 2+ When the molar amount added is small, Ni 3 S 2 The material grown on the surface of the nanowires is not uniform. Many substances extend between the nanowires to form a curved surface with the nanowire as the edge, and there are also granular material agglomeration. As can be seen from Figure (b), as Fe 2+ The increase in the molar amount added, Fe 2 O 3 Nanoparticles in Ni 3 S 2 The nanowires are distributed at intervals, showing the state of nanowire strings and balls, and the overall distribution is unif...

Embodiment 3

[0030] Figure 5 Fe prepared for Example 3 2 O 3 @Ni 3 S 2 SEM images and comparison of catalytic performance of / NF electrode materials. In order to study the effect of the hydrothermal reaction temperature on the OER properties and morphology of the material, four hydrothermal reaction temperatures of 80 °C, 90 °C, 100 °C, and 110 °C were set in the experiment. Figure 5 (a-c) show the surface morphologies of the corresponding materials at 80°C, 90°C, and 100°C. Figure (a) shows that the hydrothermal reaction temperature of 80 °C is only 3 S 2 A very small amount of nanoparticles grew on the surface of the nanowire, so the surface morphology of the sample under this condition was similar to that of Ni. 3 S 2 / NF precursor materials are very similar; it can be seen from Figure (b) that the nanoparticles are uniformly distributed along the extension direction of the nanowires, and the spacers are coated in Ni 3 S 2 nanowires. When the hydrothermal temperature is 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com