Infrared light detection method for rapidly detecting industrially discharged toluene

A detection method, infrared light technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as easy to cause danger, and achieve good results and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

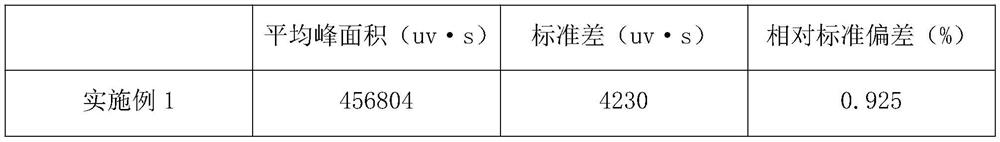

Embodiment 1

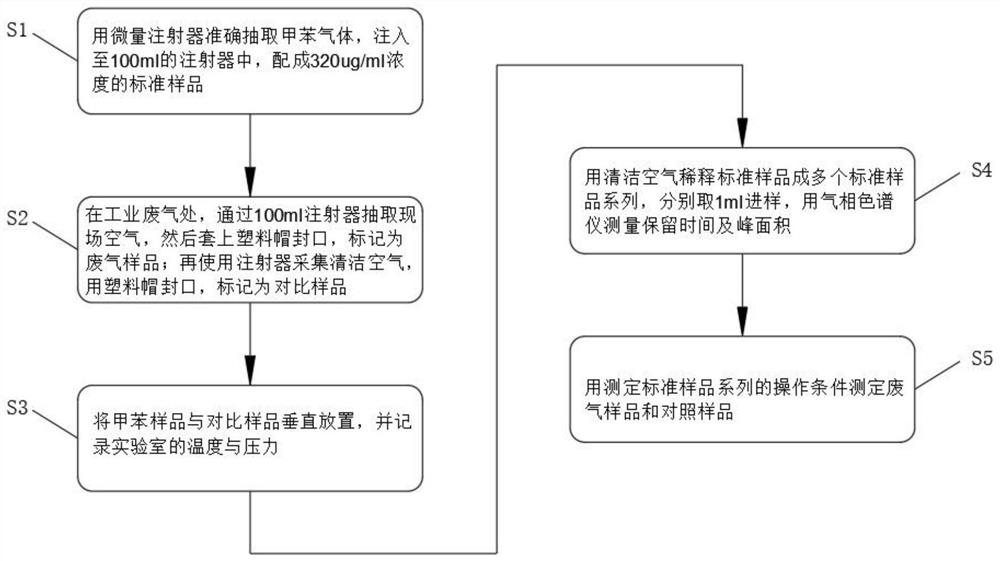

[0021] Embodiment 1 A kind of infrared light detection method of rapid detection industrial discharge toluene, comprises:

[0022] 1. Accurately extract toluene gas with a micro syringe, inject it into a 100ml syringe, and prepare a standard sample with a concentration of 320ug / ml;

[0023] 2. At the industrial waste gas place, use a 100ml syringe to wash with on-site air three times at the sampling site, extract the on-site air through the syringe, then put on a plastic cap to seal it, and mark it as an exhaust gas sample; then use the syringe to collect clean air and seal it with a plastic cap , marked as a comparison sample, the air in the syringe of the comparison sample is introduced into a clean container for storage;

[0024] 3. Place the toluene sample and the comparison sample vertically, and record the temperature and pressure of the laboratory;

[0025] 4. Dilute the standard sample with clean air to form a series of 80ug / ml standard samples, take 1ml for injection...

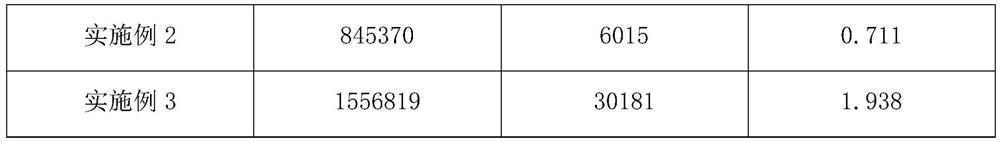

Embodiment 2

[0028] Embodiment 2 A kind of infrared light detection method of rapid detection industrial emission toluene, comprising:

[0029] 1. Accurately extract toluene gas with a micro syringe, inject it into a 100ml syringe, and prepare a standard sample with a concentration of 320ug / ml;

[0030] 2. At the industrial waste gas place, use a 100ml syringe to wash with on-site air three times at the sampling site, extract the on-site air through the syringe, then put on a plastic cap to seal it, and mark it as an exhaust gas sample; then use the syringe to collect clean air and seal it with a plastic cap , marked as a comparison sample, the air in the syringe of the comparison sample is introduced into a clean container for storage;

[0031] 3. Place the toluene sample and the comparison sample vertically, and record the temperature and pressure of the laboratory;

[0032] 4. Dilute the standard sample with clean air to form a 160ug / ml standard sample series, take 1ml for injection, m...

Embodiment 3

[0035] Embodiment 3 A kind of infrared light detection method of rapid detection industrial emission toluene, comprises:

[0036] 1. Accurately extract toluene gas with a micro syringe, inject it into a 100ml syringe, and prepare a standard sample with a concentration of 320ug / ml;

[0037] 2. At the industrial waste gas place, use a 100ml syringe to wash with on-site air three times at the sampling site, extract the on-site air through the syringe, then put on a plastic cap to seal it, and mark it as an exhaust gas sample; then use the syringe to collect clean air and seal it with a plastic cap , marked as a comparison sample, the air in the syringe of the comparison sample is introduced into a clean container for storage;

[0038] 3. Place the toluene sample and the comparison sample vertically, and record the temperature and pressure of the laboratory;

[0039] 4. Dilute the standard sample with clean air to form a 320ug / ml standard sample series, take 1ml for injection, me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com