Double-activity interface supported catalyst as well as preparation method and application thereof

A supported catalyst and dual-activity technology, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, and preparation of organic compounds, etc., can solve the problems of complex preparation process, large energy consumption, unsatisfactory space-time yield of methanol, etc., and achieve synthetic The process is simple and easy, the preparation conditions are mild, and the effect of excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

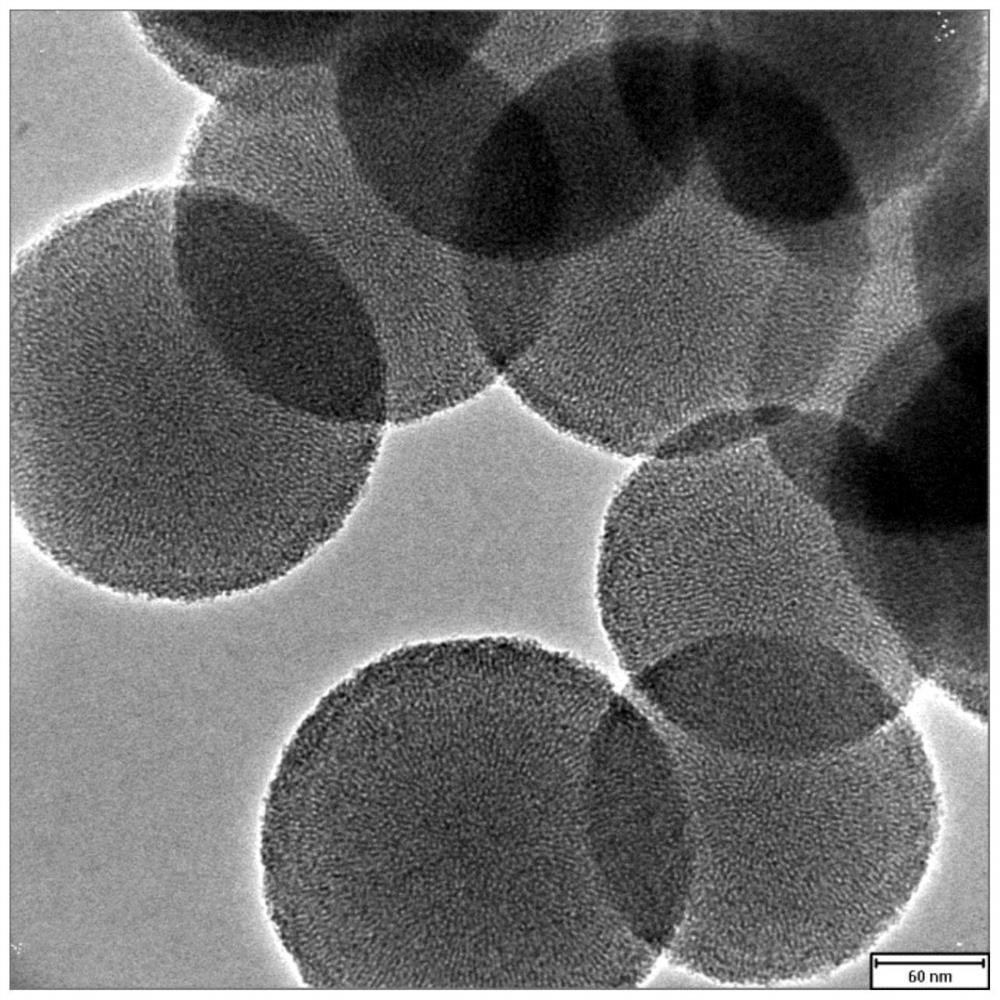

[0043] Preparation of MSS by Stober method:

[0044] Preparation of solution A: Weigh 131mg of CTAB into a 100mL reaction bottle, add 47.75mL of ultrapure water, 22.05mL of absolute ethanol and 0.4mL of ammonia (25%), and ultrasonically form a homogeneous solution A;

[0045] Prepare solution B: Add 100 μL TEOS to 10 mL of absolute ethanol and ultrasonically shake for 10 minutes to obtain solution B;

[0046] Place the reaction bottle containing solution A on a magnetic stirrer and adjust the rotation speed at 450 rpm, and add solution B dropwise to the reaction bottle under continuous stirring, wherein the first 4mL solution B is added dropwise twice with an interval of 30min , and then 6mL of solution B was added dropwise three times at intervals of 1h each time. Stir at room temperature for 24 hours from the beginning of dropwise addition of solution B, collect the sample by centrifugation, wash twice with water and once with ethanol, then dry the resulting white precipita...

Embodiment 2

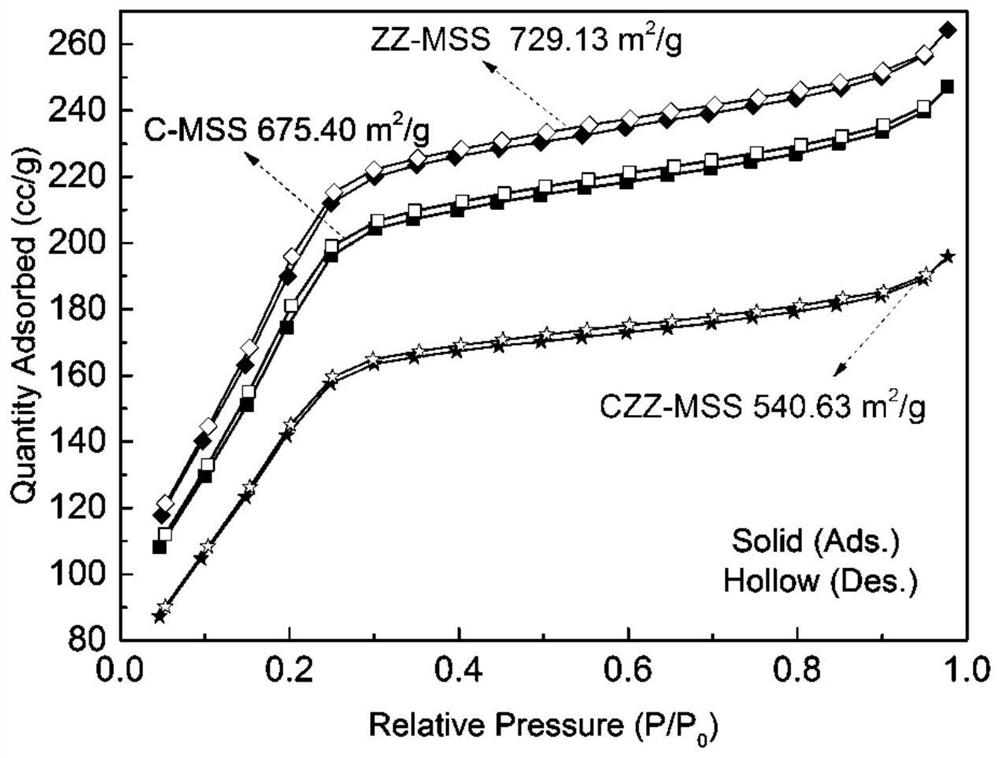

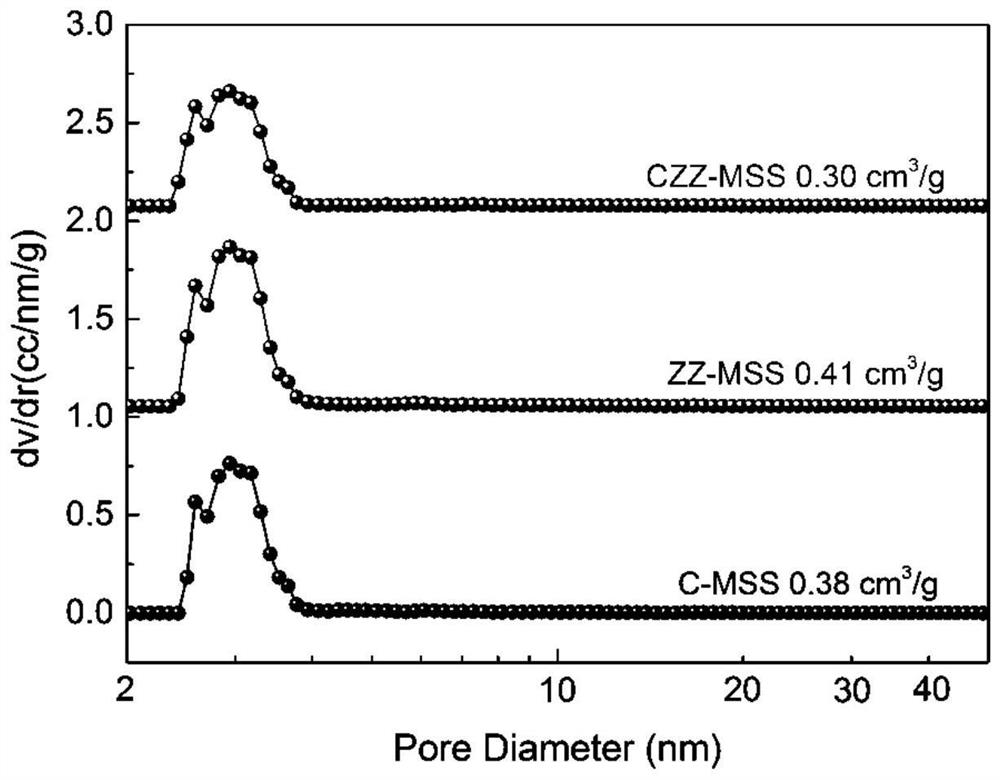

[0048] Preparation of ZnO-Cu-ZrO 2 Dual active interface supported catalyst (CZZ-MSS):

[0049] Preparation of metal ion loading solution: Weigh 566.31mg of copper nitrate trihydrate and 399.10mg of zinc nitrate hexahydrate, measure 0.96mL of zirconium nitrate solution (1mol / L) in a 15mL centrifuge tube, then add 10mL of a mixed solution of ethanol and water, The volume ratio of ethanol to water is 1:1.

[0050] Preparation of pore-confined dual-active interface-supported catalyst: Weigh 100 mg of the activated MSS prepared in Example 1 into a 30 mL ceramic crucible, take 2 mL of the metal ion loading solution prepared above, and add it dropwise to the crucible in batches. The batch dosage is added dropwise in the following order: 800μL→400μL→400μL→400μL, and after each batch is added, it needs to be shaken in an ultrasonic instrument until there is no obvious moisture, and the next batch of loading should be carried out after drying in an oven at 80°C Dropping of liquid. A...

Embodiment 3

[0052] Preparation of C-MSS supported catalyst:

[0053] Preparation of metal ion loading solution: Weigh 566.31 mg of copper nitrate trihydrate into a 15 mL centrifuge tube, then add 10 mL of a mixed solution of ethanol and water, wherein the volume ratio of ethanol and water is 1:1.

[0054] To prepare a pore-confined highly dispersed active site-supported catalyst, weigh 100 mg of the activated MSS prepared in Example 1 in a 30 mL ceramic crucible, take 2 mL of the metal ion loading solution prepared above, and add it dropwise in batches to the crucible. The amount of each batch is added dropwise in the following order: 800μL → 400μL → 400μL → 400μL, and after each batch is added, it needs to be shaken in an ultrasonic instrument until there is no obvious moisture, and the next batch should be dried in an oven at 80°C Dropwise addition of load solution. After adding all the load liquids, transfer the MSS containing the load liquid to the muffle furnace for two-stage calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com