Method for treating dye wastewater by using biomass and fungi

A dye wastewater and biomass technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of complex treatment process, unsatisfactory treatment effect, high cost, etc., and achieve simple operation , reduce the amount of use, reduce the effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Pretreatment of waste straw

[0045] In order to increase the contact area of straw to dye wastewater and improve the adsorption efficiency, and at the same time facilitate the filtration and separation of straw and dye wastewater, the straw needs to be screened and pretreated. The specific process is as follows: use a guillotine to cut wheat straw, peanut shells, and corn straw into specifications It is a small section of 1-3cm, and it is ready to use after drying naturally outside.

Embodiment 2

[0046] Embodiment 2: Screening, purification, and rejuvenation of Mypopora haemorrhoids, Pleurotus ostreatus, and Lentinus edodes strains

[0047] Separation and screening were carried out by tissue imprinting method, and the separation and screening method was as follows: put rotten wood, fruiting bodies of Pleurotus ostreatus and fruiting bodies of Lentinus edodes in a beaker, and soak them in sterile water for 2 hours. The liquid samples were then diluted into different gradients and plated on PDA (20% potato extract, 2% glucose, 2% agar) medium containing 4% 2,6-dimethoxybenzene. Observe the growth of the colony on the medium every day and whether there is a red discoloration circle around the colony, select the strains with a red discoloration circle around the colony and transfer them to a new PDA medium, and finally obtain the purified strain. The purified strains were inoculated on the PDA slant and stored in a refrigerator at 4°C for subsequent use.

[0048] In order...

Embodiment 3

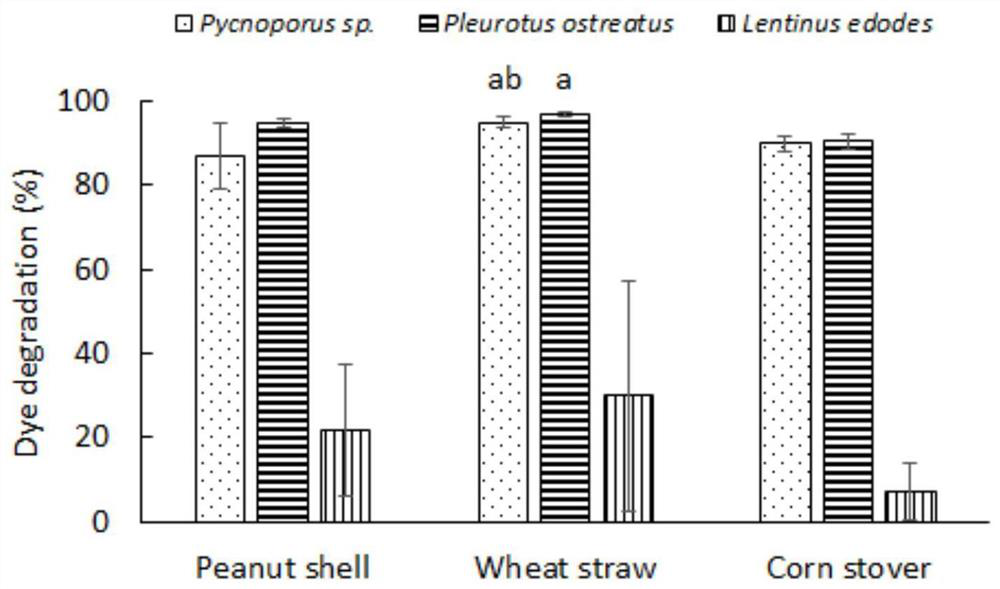

[0049] Example 3: Adsorption of wheat stalks, peanut shells, and corn stalks to dye wastewater

[0050] Compared with the traditional physical method, chemical method and biochemical method to treat dye wastewater, the biological method adopted in this technology uses straw waste as the adsorbent, and its adsorption efficiency reaches about 90%, realizing the concept of "treating waste with waste" . On this basis, the growth and metabolism of fungi are used to degrade the pollutants in the dye wastewater, and the effective removal is truly realized without secondary pollution. Increase farmers' income while reducing corporate governance costs.

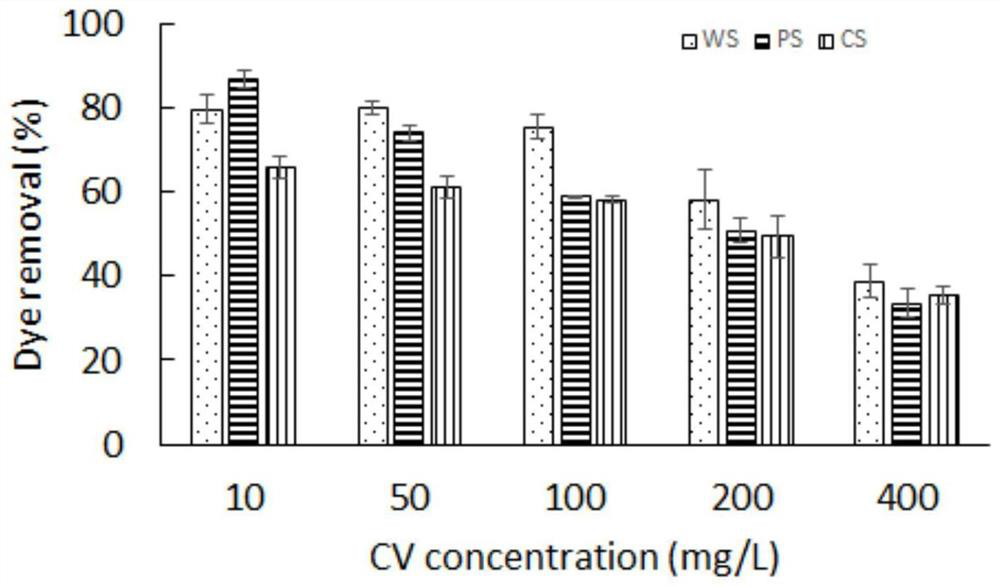

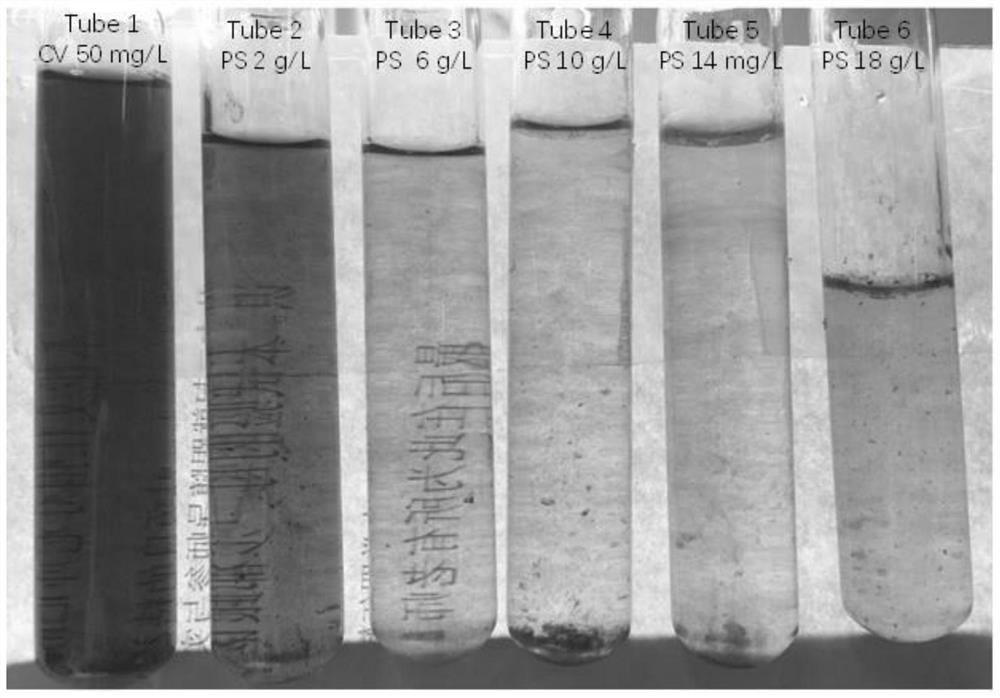

[0051] Effect of dye wastewater concentration on adsorption effect: adjust the concentration of dye wastewater to 10, 50, 100, 200, 400mgL respectively -1 , add 2gL -1 Add wheat stalks, peanut shells, and corn stalks to a centrifuge tube containing 50 ml of dye wastewater. After shaking at natural pH and room temperature for 12 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com