Sports protective lens resin monomer, preparation method and production system thereof

A technology of resin monomer and production system, applied in the field of sports protective lens resin monomer, preparation method and production system thereof, to achieve the effects of saving heating or cooling time, good heat resistance, and improving flexibility performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

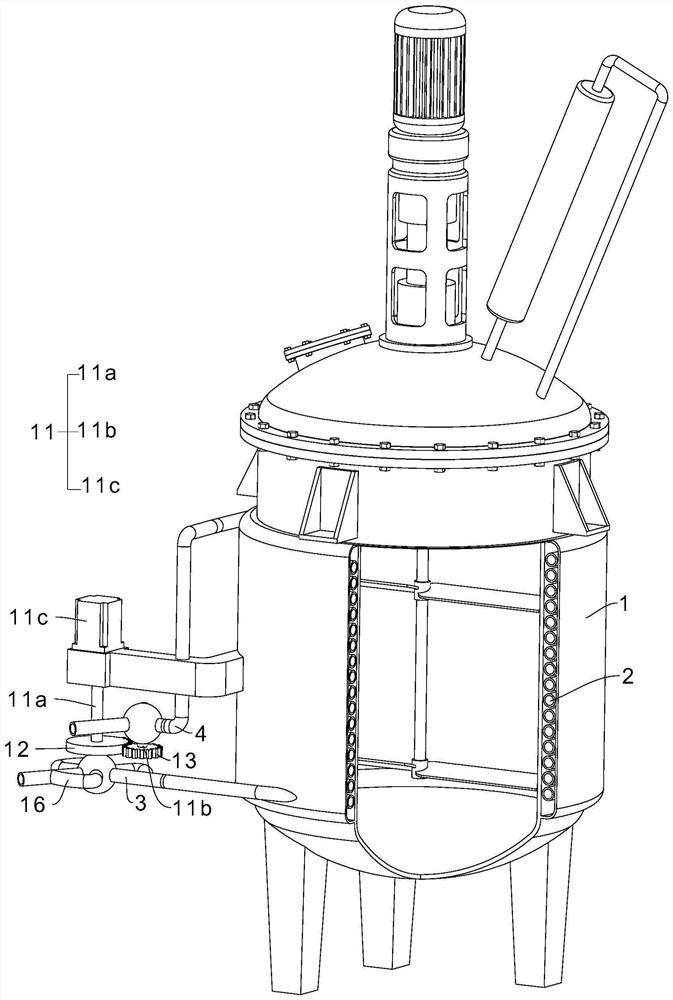

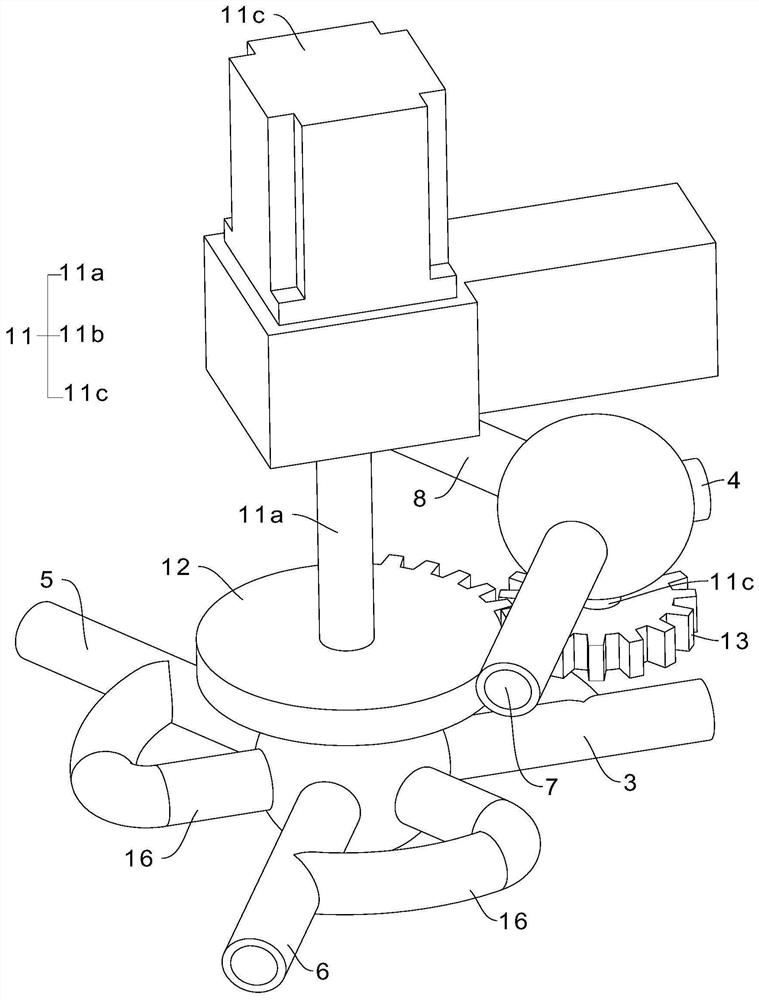

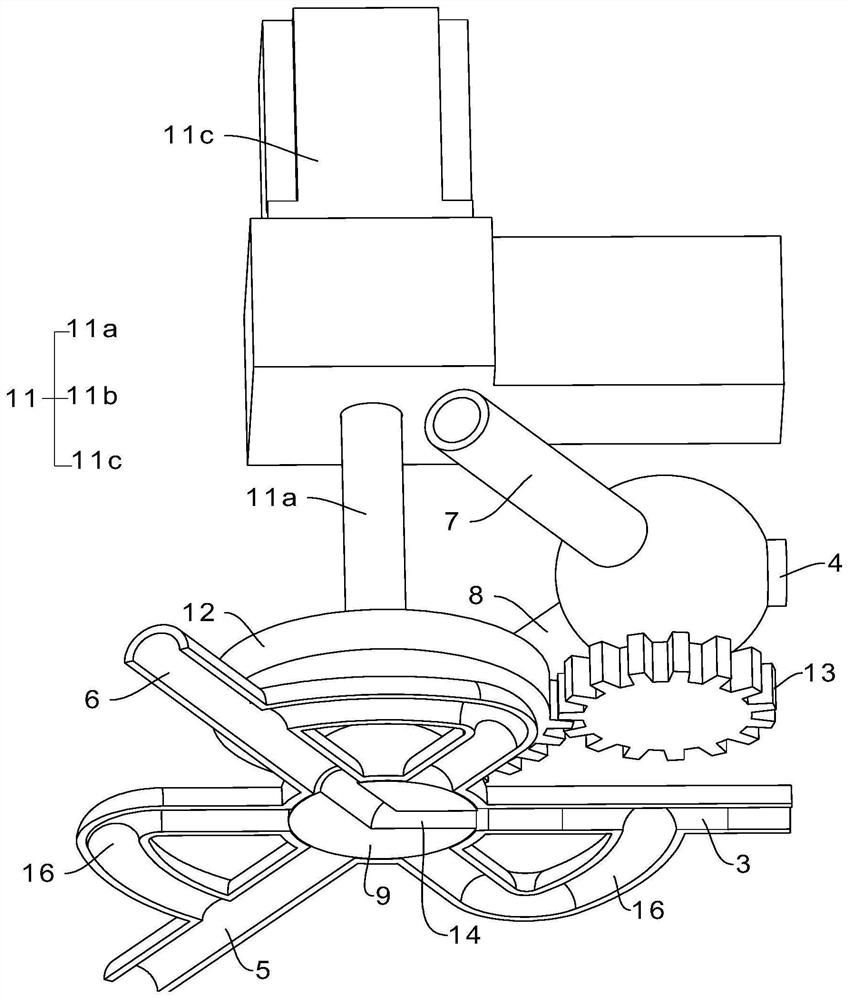

Image

Examples

Embodiment 1

[0036] A sports protective lens resin monomer, the parts by weight of each component are:

[0037]

[0038] The sum of the parts by weight of the above components is 100 parts.

[0039] A method for preparing the sports protective lens resin monomer as described above, the preparation method comprising the following steps:

[0040] S1, put the following components by mass: 900 parts of dimethyl isophthalate, 990 parts of allyl alcohol and 9 parts of catalyst calcium hydroxide into the replacement reactor, stir at normal pressure and heat up to 95 °C, and then keep stirring After 17 hours of reaction, a substitution reaction occurs to generate a diallyl isophthalate crude product; the substitution reactor is provided with a condensation reflux device, and the allyl alcohol vapor generated in the reaction process is condensed and refluxed, and the uncondensed gas and the methanol vapor generated by the reaction are reflowed. Methanol is recovered through three-stage condensati...

Embodiment 2

[0046] A sports protective lens resin monomer, the parts by weight of each component are:

[0047]

[0048] The sum of the parts by weight of the above components is 100 parts.

[0049] A method for preparing the sports protective lens resin monomer as described above, the preparation method comprising the following steps:

[0050] S1, put the following components by mass: 1100 parts of dimethyl isophthalate, 810 parts of allyl alcohol and 11 parts of catalyst calcium hydroxide into the replacement reactor, stir at normal pressure and heat up to 115 °C, and then keep stirring After 21 hours of reaction, a substitution reaction occurs to generate diallyl isophthalate crude product; the substitution reaction kettle is equipped with a condensation reflux device, and the allyl alcohol vapor generated in the reaction process is refluxed after condensation, and the uncondensed gas and the methanol vapor generated by the reaction are reflowed. Methanol is recovered through three-...

Embodiment 3

[0056] A sports protective lens resin monomer, the parts by weight of each component are:

[0057]

[0058] The sum of the parts by weight of the above components is 100 parts.

[0059] A method for preparing the sports protective lens resin monomer as described above, the preparation method comprising the following steps:

[0060] S1, put the following components by mass: 1,000 parts of dimethyl isophthalate, 900 parts of allyl alcohol and 10 parts of catalyst calcium hydroxide into the replacement reactor, stir at normal pressure and heat up to 105°C, and then keep stirring After reacting for 19 hours, a substitution reaction occurred to generate crude diallyl isophthalate; the substitution reaction kettle was equipped with a condensation reflux device, and the allyl alcohol vapor produced in the reaction process was condensed and refluxed, and the uncondensed gas and the methanol vapor generated by the reaction were reflowed. Methanol is recovered through three-stage co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com