Crystal silicon solar cell variable-temperature diffusion furnace

A solar cell and diffusion furnace technology, which is applied in the direction of diffusion/doping, circuit, crystal growth, etc., can solve the problems of health damage of operators, silicon wafers are prone to produce harmful gases, and sealing is not good enough, so as to improve the heat insulation performance and airtightness, good airtightness, and the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

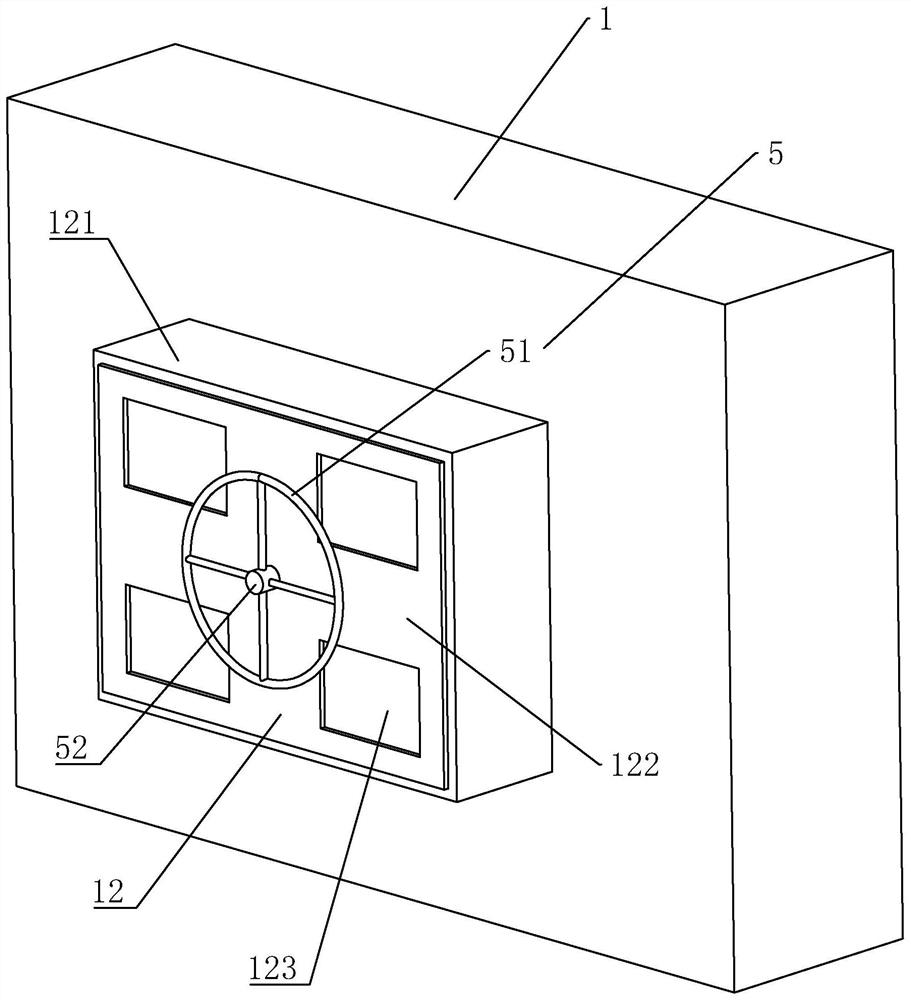

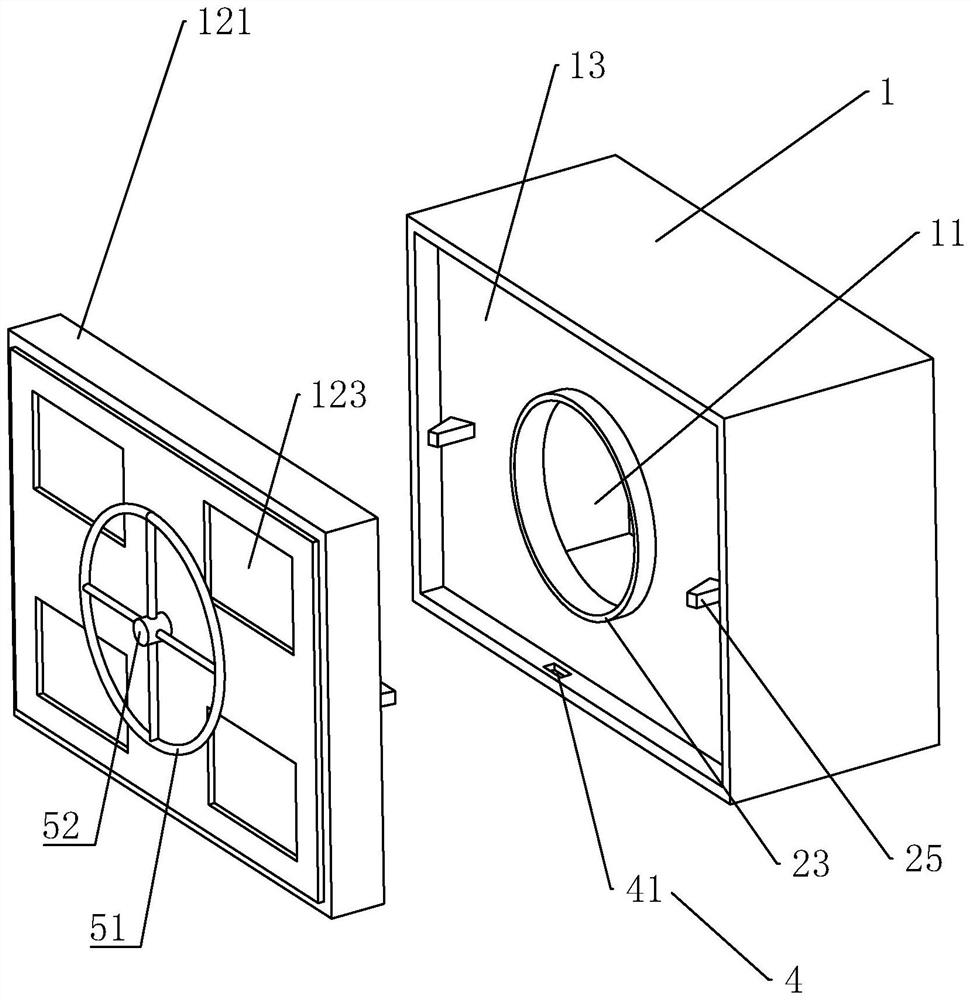

[0032] A temperature-variable diffusion furnace for crystalline silicon solar cells provided in this embodiment has a structure such as Figure 1-3 Shown, comprise furnace body 1, be provided with furnace mouth 11 on the furnace body 1, be provided with the furnace door 12 that is used to close furnace mouth 11 on the furnace body 1 hinge of furnace mouth 11 side, furnace mouth 11 is circular shape setting, furnace The door 12 is provided with a closing part 2 , an auxiliary insulating part 3 and a locking part 4 .

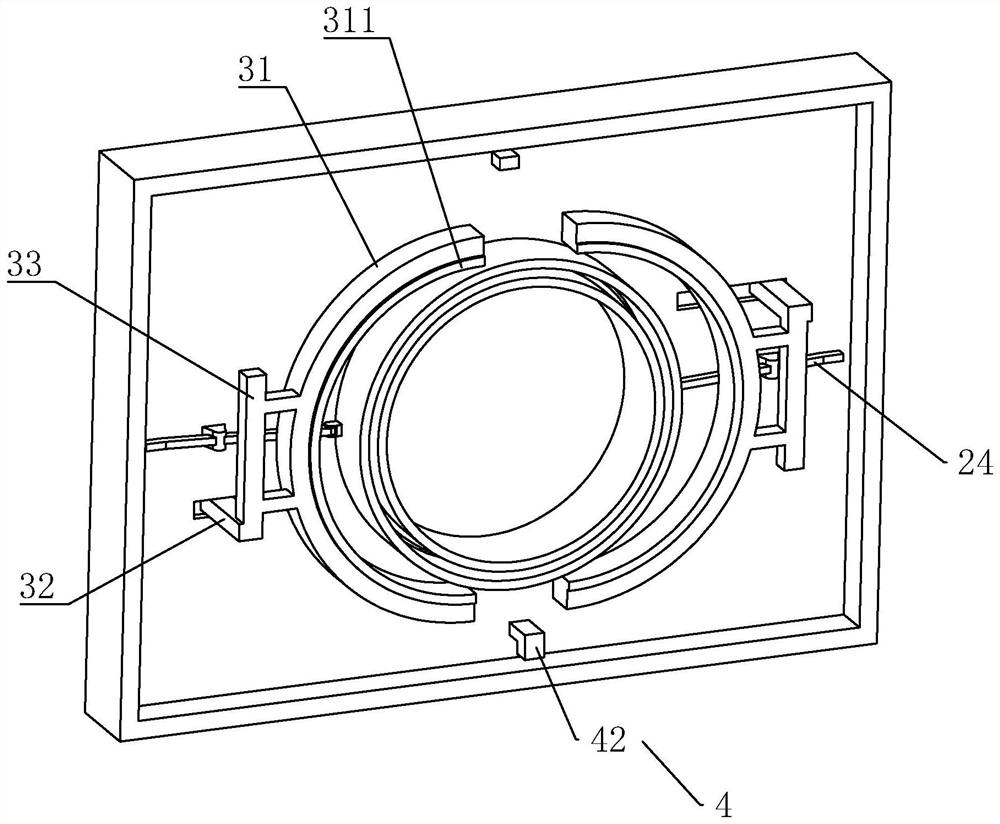

[0033] Such as Figure 2-4 As shown, the closure 2 includes a fixed ring 21 formed on the furnace door 12, and a closed ring 22 with the same shape as the furnace mouth 11 is slidably connected to the outside of the fixed ring 21, which is used for sliding and clamping when the furnace door 12 is closed. Outside the furnace mouth 11 and close the furnace mouth 11, the furnace mouth 11 is provided with a connecting ring 23 whose shape matches the fixed ring 21. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com