Ink-jet ink and preparation method and application thereof

A technology of inkjet ink and reactive dyes, applied in the field of materials, can solve the problems of limited improvement of color fixation rate, achieve the best storage stability, easy to use and easy to operate, and easy to popularize and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

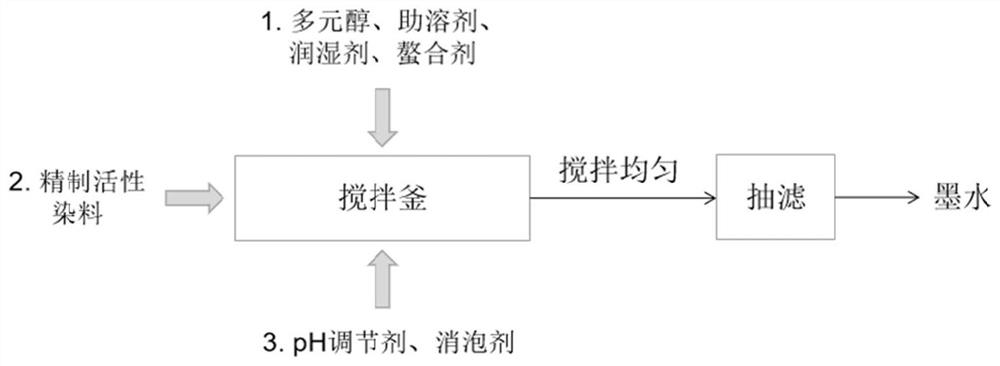

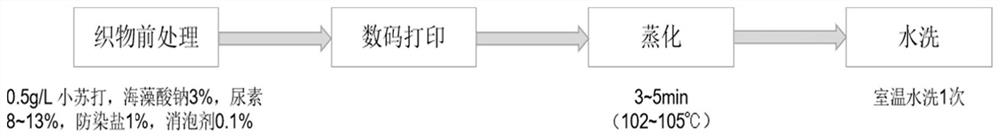

Method used

Image

Examples

Embodiment 1

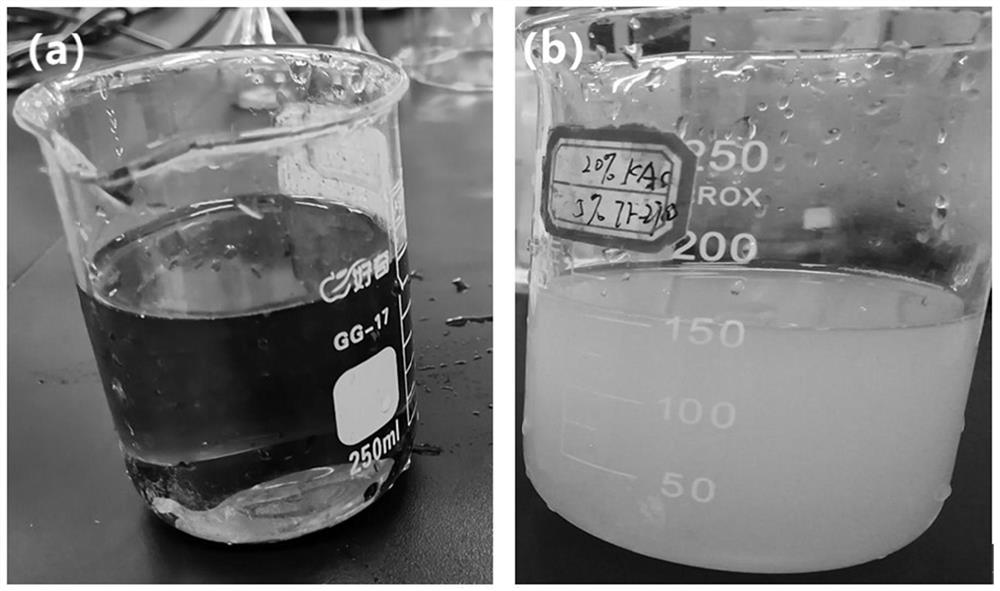

[0062] The inkjet ink in this example includes ethylene glycol 23.5g, 1,2-hexanediol 1.5g, N-methylpyrrolidone 1g, wetting agent S465 1g, fatty alcohol polyoxyethylene ether AEO-3 0.1g, 0.1g of ethylenediaminetetraacetic acid, 0.1g of triethanolamine, 62.6g of deionized water, desalted and refined red reactive dye (containing 1 fluoro-s-triazine, 1 chloro-s-triazine and 1 vinylsulfone sulfate active base) 10g, antibacterial agent Proxel GXL 0.1g.

[0063] The inkjet ink in this example was prepared by the following method:

[0064] Weigh 23.5g of ethylene glycol, 1.5g of 1,2-hexanediol, 1g of N-methylpyrrolidone, 1g of wetting agent S465, 0.1g of fatty alcohol polyoxyethylene ether AEO-3, and 0.1g of ethylenediaminetetraacetic acid , 0.1g of triethanolamine, 62.6g of deionized water, 10g of desalted and refined red reactive dye, stirred and dissolved, added 0.1g of antibacterial agent Proxel GXL, and continued to stir and dissolve, and then used 0.2um water-based filter membr...

Embodiment 2

[0067] The inkjet ink in this example includes ethylene glycol 23g, 1,2-hexanediol 2g, N-methylpyrrolidone 0.5g, wetting agent S4652g, fatty alcohol polyoxyethylene ether AEO-3 0.1g, ethylene diol 0.1g of amine tetraacetic acid, 0.1g of triethanolamine, 62.1g of deionized water, desalted and refined yellow reactive dye (containing 1 fluoro-s-triazine, 1 fluorochloropyrimidine and 1 vinylsulfone sulfate active group) 10 g, antibacterial agent Proxel GXL 0.1 g.

[0068] The inkjet ink in this example was prepared by the following method:

[0069] Weigh 23g of ethylene glycol, 2g of 1,2-hexanediol, 0.5g of N-methylpyrrolidone, 2g of wetting agent S465, 0.1g of fatty alcohol polyoxyethylene ether AEO-3, 0.1g of ethylenediaminetetraacetic acid, 0.1g of triethanolamine, 62.1g of deionized water, 10g of yellow reactive dye refined by desalination, stirring and dissolving, adding 0.1g of antibacterial agent Proxel GXL, and continuing stirring and dissolving, then adopting 0.2um water...

Embodiment 3

[0071] The inkjet ink in this example includes ethylene glycol 23g, 1,2-hexanediol 2g, N-methylpyrrolidone 0.5g, wetting agent S4653g, fatty alcohol polyoxyethylene ether AEO-3 0.2g, ethylene diol 0.1g of amine tetraacetic acid, 0.1g of triethanolamine, 61g of deionized water, 10g of demineralized and refined orange reactive dye (containing 2 fluoro-s-triazine and 1 vinylsulfone sulfate active group), antibacterial agent Proxel GXL 0.1 g.

[0072] The inkjet ink in this example was prepared by the following method:

[0073] Weigh 23g of ethylene glycol, 2g of 1,2-hexanediol, 0.5g of N-methylpyrrolidone, 3g of wetting agent S465, 0.2g of fatty alcohol polyoxyethylene ether AEO-3, 0.1g of ethylenediaminetetraacetic acid, Triethanolamine 0.1g, deionized water 61g, desalination refined orange reactive dye 10g, stirring and dissolving, adding antibacterial agent Proxel GXL 0.1g, and continuing to stir and dissolve, then adopting 0.2um water-based filter membrane suction filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com