Battery pole piece, preparation method thereof, and lithium-ion battery

A lithium-ion battery, pole piece technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve the problems of reducing battery energy density, increasing processes, reducing consistency, etc., to improve energy density, improve rolling Compression density, effect of changing the number of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

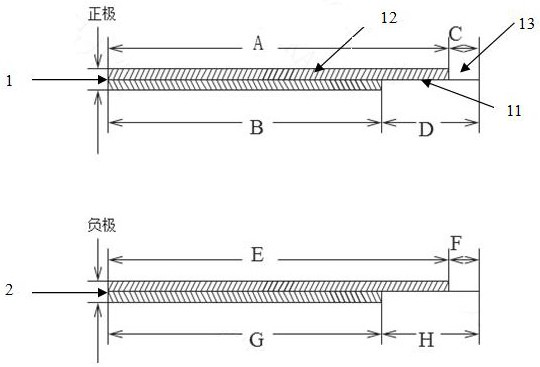

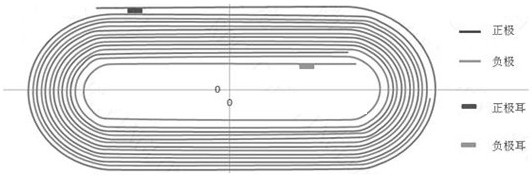

[0047] Example 1: figure 1 A lithium-ion battery pole piece is shown, including a positive electrode sheet 1 and a negative electrode sheet 2; the positive electrode sheet includes a positive electrode current collector 11, a positive electrode coating layer 12, and a positive aurora foil layer 13; the positive aurora foil layer includes The first positive aurora foil layer and the second positive aurora foil layer ( figure 1 The position of the first positive aurora foil layer and the second positive aurora foil layer coincide, the position of the second positive aurora foil layer remains unchanged, and the change of resistance is realized by changing the position of the first positive aurora foil layer); the positive electrode coating layer The end is the second positive aurora foil layer, and the first positive aurora foil layer divides the positive electrode coating layer into the first positive electrode coating layer and the second positive electrode coating layer; the p...

Embodiment 2

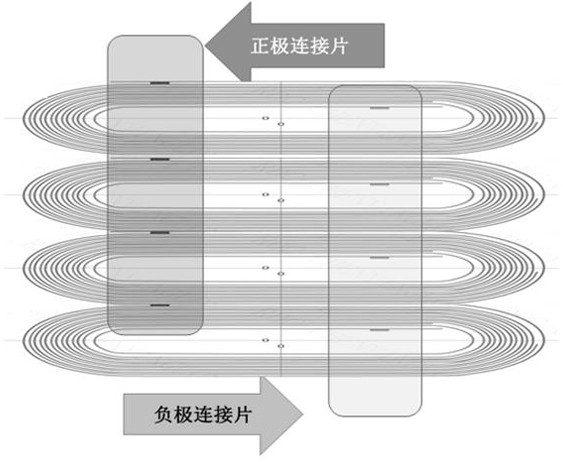

[0055] Embodiment 2: In another embodiment of the present application, similar to Embodiment 1, the only difference is that the position of the first positive aurora foil layer is different, such as Figure 4-5 It is shown that the position of the first positive aurora foil layer is at 1 / 10-9 / 10 of the positive plate, by Image 6 According to the simulation calculation, compared with the negative tab, the potential potential of the positive tab welding position is the lowest, and at the same time, Figure 7 As shown, the position of the tab (that is, the position of the first positive aurora foil layer), under the simulated rate discharge, under the state of 100% SOC 1C discharge for 10s, the internal resistance is the smallest at the 40% position, so Example 2 adopts 40% position for welding. The battery electrode group is made into a lithium-ion battery, the AC internal resistance of the battery is 3.4-3.8mΩ, the AC internal resistance can be reduced by more than 30%, and t...

Embodiment 3

[0056] Embodiment 3: In another embodiment of the present application, similar to Embodiment 1, the only difference is the structure of two positive and one negative tabs, Figure 8 It is shown that the position of the first positive aurora foil layer is at 5 / 10 of the positive electrode sheet, and the position of the second positive aurora foil layer is at the end of the positive electrode sheet. The battery pole assembly was made into a lithium-ion battery, and the AC internal resistance of the battery was 2.5-2.9mΩ. Compared with Example 2, the internal resistance was reduced by 24%, and the battery capacity was 22-24Ah.

[0057] Figure 9 Changes in resistance of Examples 1, 2, and 3 are shown.

[0058] Figure 10The preparation method of described lithium-ion battery pole piece is shown, comprises the following steps:

[0059] (1) Coating the coating layer on one side of the positive current collector according to the set size intervals to form multiple pole group unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com