Preparation method of wear-resistant coating of screw compressor and screw compressor

A screw compressor, wear-resistant coating technology, applied in coatings, mechanical equipment, machines/engines, etc., can solve problems such as affecting the service life of the coating, coating peeling, volumetric efficiency and energy efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

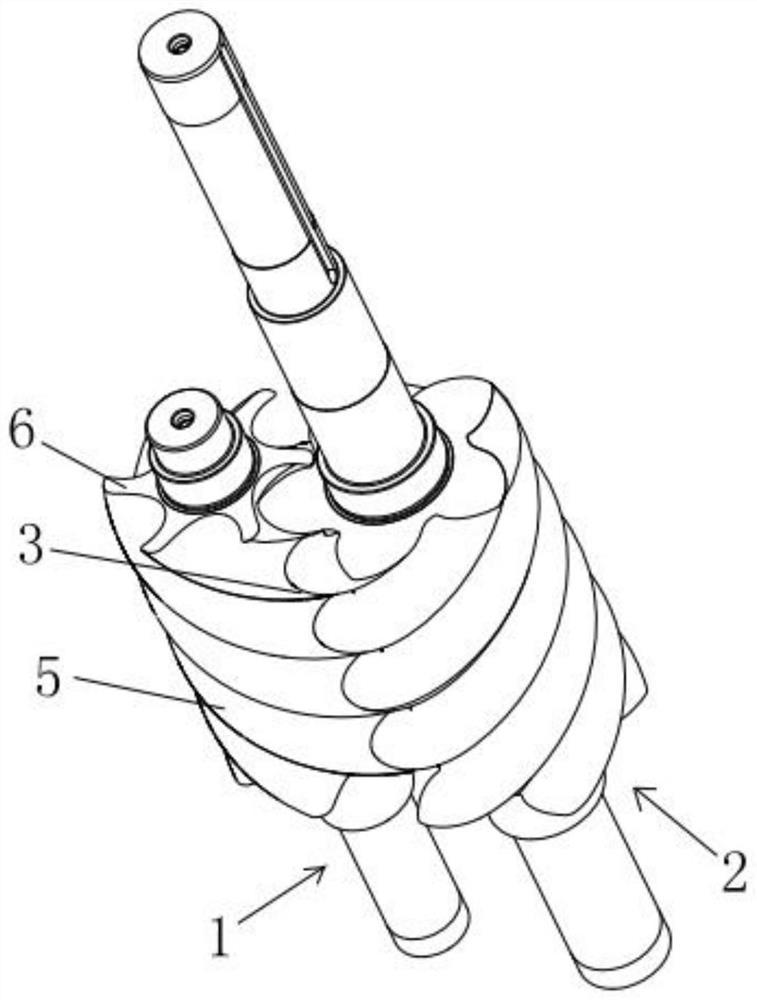

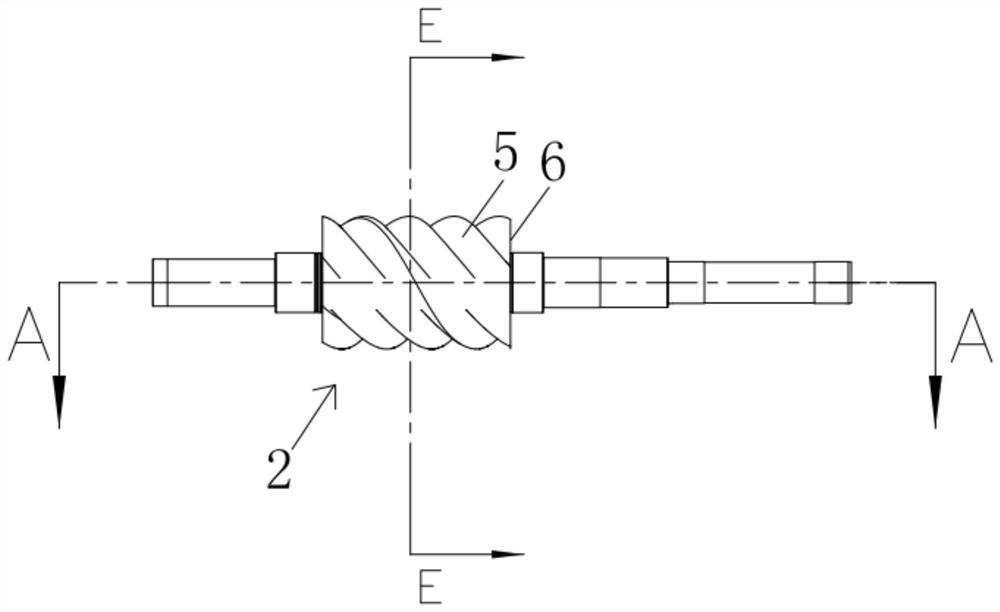

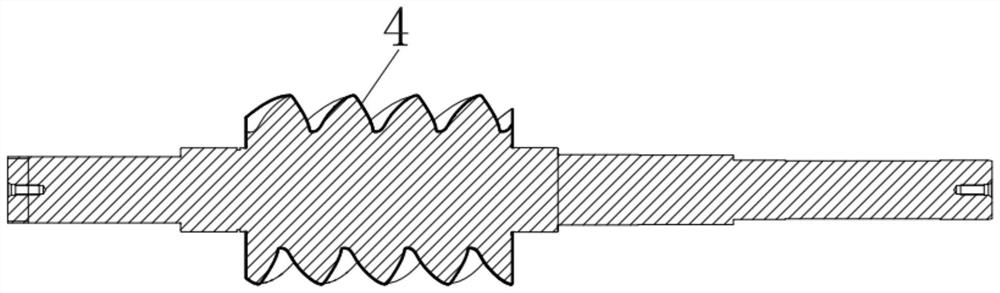

[0039] The method of preparing the wear resistant coating of the screw compressor disclosed in this example, which can be found Figure 1 - Figure 7 , Including the following steps,

[0040] S1, using a screw compressor of the impurities 1 and the yang rotor 2, engage the test with the catholic rotor 1 and the male rotor 2, the diamond rotor 1 and the yang rotor 2 maintain a certain engagement gap 3; the diamond rotor 1 and / or Yang rotor 2 After the surface of the rotor, after removing the oil, the surface of the rotor is blown; maintaining a certain meshing gap 3 facilitates mounting the rotor and facilitating the rotor operation, removing the surface of the rotor and blows to remove the surface of the rotor surface, avoiding the subsequent subsequent The adhesion effect of the coating, preferably, is blown with compressed air.

[0041] S2, sandblasted with sand blasting, after sandblasting, after sandblasting, cleaning the sand on the surface of the rotor; sandblasted on the su...

Embodiment 2

[0054] A method of preparing a wear resistant coating screw compressor according to the present embodiment is disclosed, wherein the see Figure 1 - Figure 7 Comprising the steps of,

[0055] Sl, using a screw compressor female rotor 2 and a male rotor, a female rotor and engaging again the male rotor assembly 12, so that the male rotor and a female rotor 2 meshing gap 3 remains constant; on female rotor and / or the male rotor 1 after degreasing the surface of the rotor 2, degreasing, drying rotor surface; 3 remains constant meshing gap convenient and easy operation of the rotor mounting the rotor on the rotor surface degreasing and drying, the surface of the rotor to remove stains, to avoid affect the subsequent paint adhesion results, preferably, blown dry with compressed air.

[0056] S2, after the rotor surface blasting, blasting sand blasting machine, sand clean surface on the rotor; sandblasting the surface of the rotor, the rotor can remove the surface oxide, carbide passiv...

Embodiment 3

[0069] A method of preparing a wear resistant coating screw compressor according to the present embodiment is disclosed, wherein the see Figure 1 - Figure 7 Comprising the steps of,

[0070] Sl, using a screw compressor female rotor 2 and a male rotor, a female rotor and engaging again the male rotor assembly 12, so that the male rotor and a female rotor 2 meshing gap 3 remains constant; on female rotor and / or the male rotor 1 after degreasing the surface of the rotor 2, degreasing, drying rotor surface; 3 remains constant meshing gap convenient and easy operation of the rotor mounting the rotor on the rotor surface degreasing and drying, the surface of the rotor to remove stains, to avoid affect the subsequent paint adhesion results, preferably, blown dry with compressed air.

[0071] S2, after the rotor surface blasting, blasting sand blasting machine, sand clean surface on the rotor; sandblasting the surface of the rotor, the rotor can remove the surface oxide, carbide passiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com