Aluminum alloy consumable electrode arc welding equipment and welding method

A welding method and aluminum alloy technology, which is applied in the field of aluminum alloy welding, can solve the problems of poor fusion between welding and base metal, easy deformation, fast cooling speed, etc., and achieve the effect of improving fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the related art, aluminum alloy thin plate arc welding equipment can prepare qualified aluminum alloy arc welding seams, but there is currently no independent research and development equipment in China. When conventional arc welding equipment welds thin plates, due to the excellent thermal conductivity of aluminum alloy, the welding equipment lasts for a long time. The input heat increases the welding heat, and the deformation of the workpiece after welding is serious; this also means that the equipment and process must be redeveloped, and the cost increases sharply; Low-temperature forming produces a large temperature difference, and the surface / interface of the aluminum alloy base metal forms dense and refractory Al 2 o 3 , so that Al2O3 hinders the fusion and alloying between metals, and the weld fusion is poor.

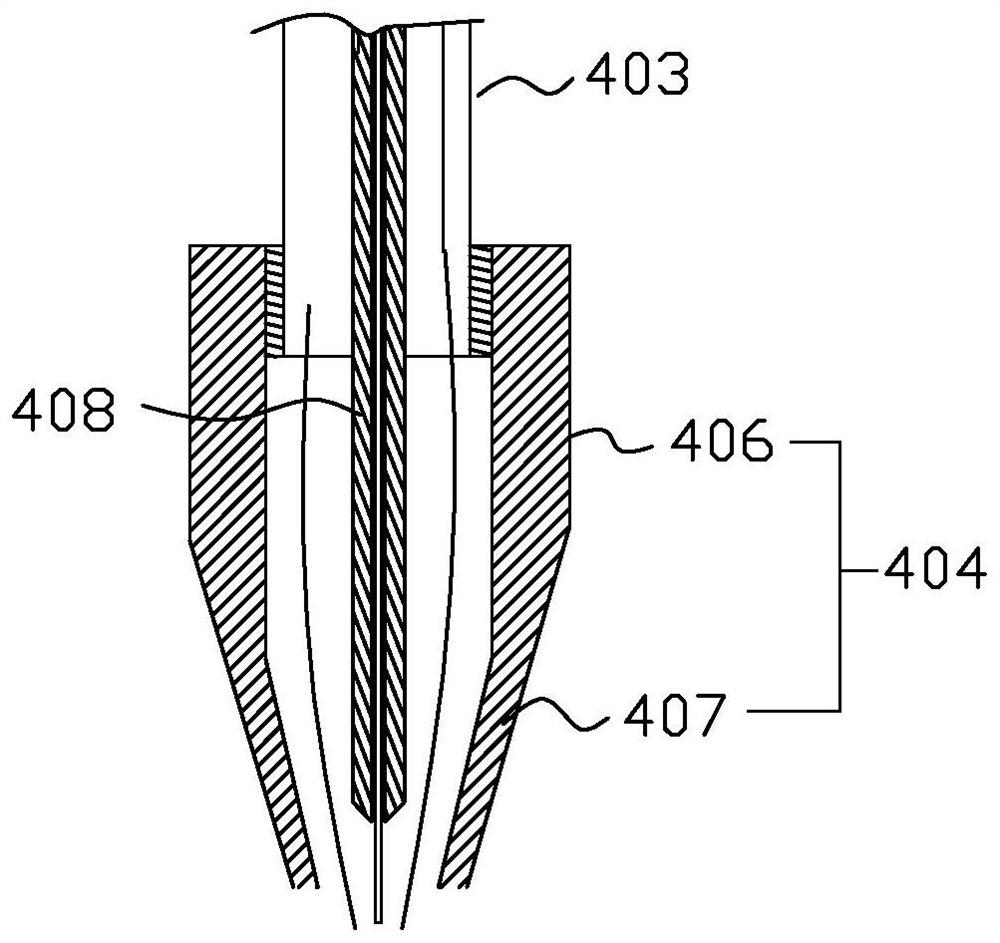

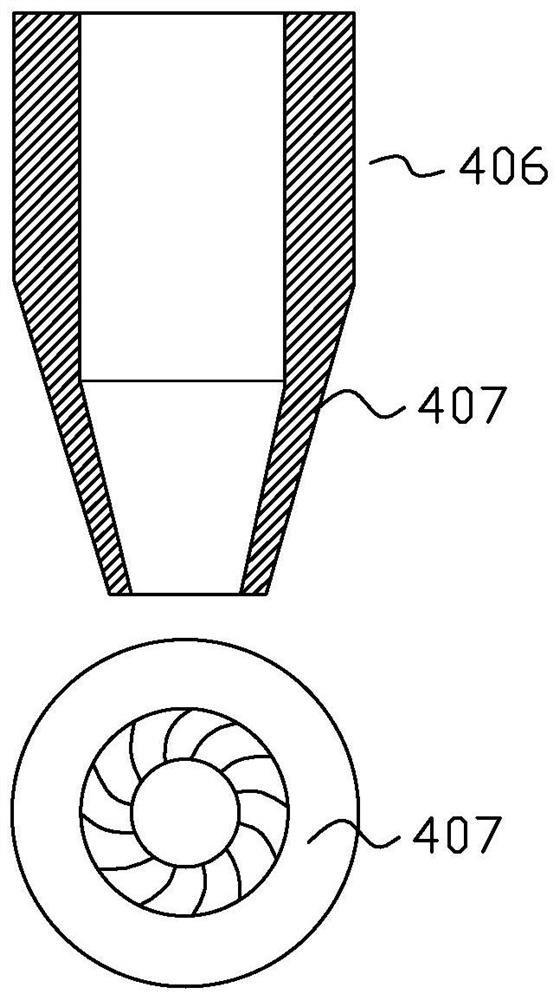

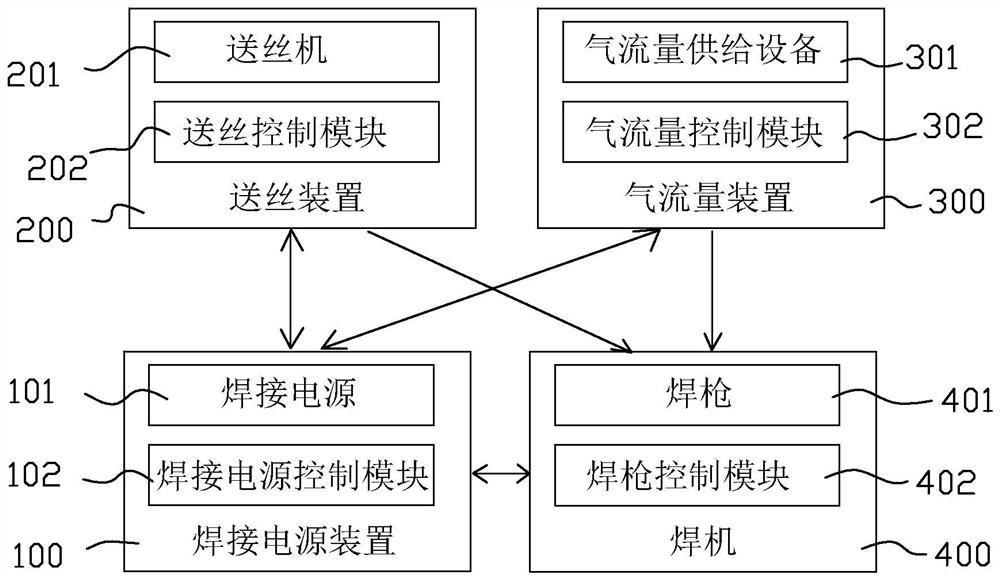

[0044] In view of this, the present invention provides an aluminum alloy arc welding torch, arc welding equipment and a corresponding welding method, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com