Light stone-plastic clay and preparation method thereof

A stone-plastic, lightweight technology, used in the field of clay material processing and production, can solve the problems of laborious production and hard material, and achieve the effect of accelerated drying speed, good softness, and light texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

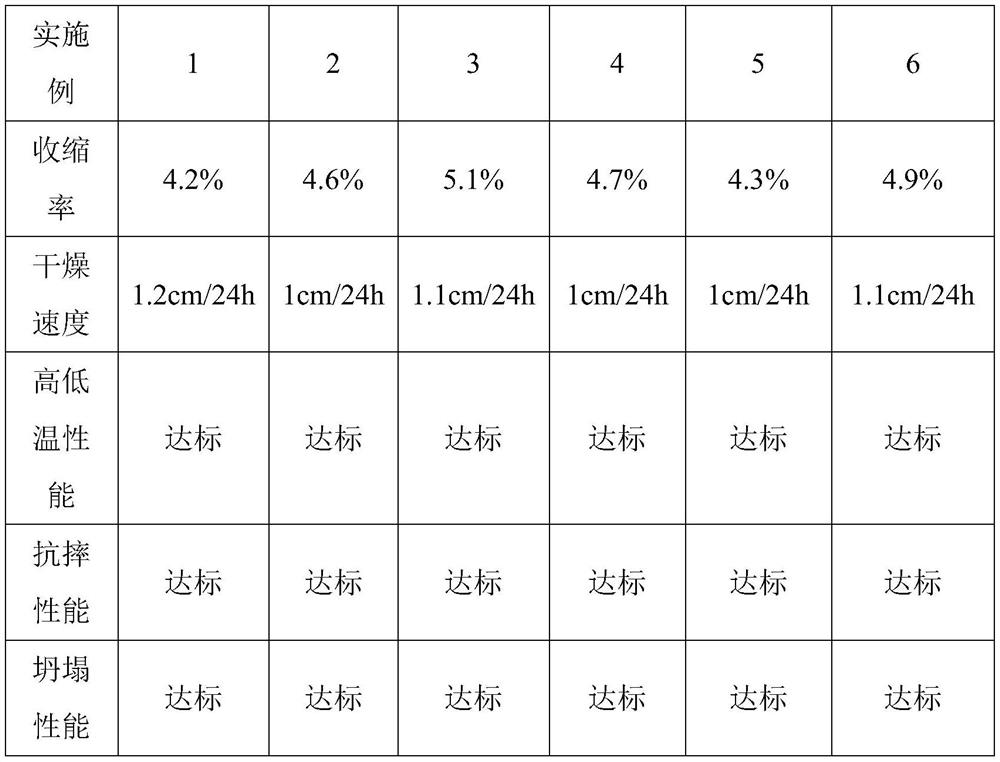

Examples

Embodiment 1

[0021] A light stone plastic clay, made of the following raw materials in parts by weight: 41 parts of nanoscale shell powder, 15 parts of gypsum powder, 9 parts of calcined kaolin, 11 parts of lignin fiber, 12 parts of water, and 6 parts of polyvinyl acetate emulsion , 3 parts of peach gum, 2 parts of glycerin, 0.5 part of silane coupling agent KH570, 0.5 part of phenoxyethanol.

[0022] The method for preparing lightweight stone plastic clay, comprises the following steps:

[0023] 1) Preparation of calcined kaolin: put kaolin in a high-temperature-resistant container, add ammonium chloride particles of 10% of the mass of the kaolin, mix evenly, and place the high-temperature-resistant container containing kaolin and ammonium chloride particles in a muffle furnace Heating, set the heating rate at 2°C / min, program the temperature up to 400°C, deflate until there is little or no smoke, close the door of the muffle furnace, continue to heat up to 550°C at a heating rate of 3°C / ...

Embodiment 2

[0026] A light stone plastic clay, made of the following raw materials in parts by weight: 42 parts of nanoscale shell powder, 10 parts of gypsum powder, 8 parts of calcined kaolin, 14 parts of lignin fiber, 12 parts of water, and 6 parts of polyvinyl acetate emulsion , 3 parts of peach gum, 4 parts of glycerin, 0.4 parts of silane coupling agent KH570, 0.6 parts of phenoxyethanol.

[0027] The preparation method of this embodiment refers to embodiment 1.

Embodiment 3

[0029] A light stone plastic clay, made of the following raw materials in parts by weight: 40 parts of nanoscale shell powder, 10 parts of gypsum powder, 11 parts of calcined kaolin, 16 parts of lignin fiber, 9 parts of water, and 6 parts of polyvinyl acetate emulsion , 5 parts of peach gum, 2 parts of glycerin, 0.6 parts of silane coupling agent KH570, 0.4 parts of phenoxyethanol.

[0030] The preparation method of this embodiment refers to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com