Baking-free brick and preparation method thereof

A technology of unburned bricks and press molding, which is applied in landfill technology, sustainable waste treatment, solid waste management, etc., and can solve problems such as low waste utilization rate, low block forming pressure, and low compressive strength , to achieve the effect of outstanding environmental benefits, low cost, and increased folding ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

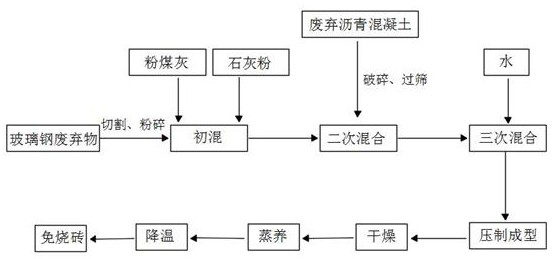

Method used

Image

Examples

Embodiment 1

[0032] First, the waste asphalt concrete is crushed to destroy the cementation of asphalt between the aggregates to form a single-grain structure of asphalt wrapped around the aggregates, and then sieved, and the particle size of the waste asphalt concrete obtained after sieving is between 3 and 5mm; The FRP waste is cut into small pieces, and then the small pieces of FRP waste are crushed by crushing equipment to obtain FRP regenerated powder and FRP regenerated fiber. The FRP regenerated powder is fluffy and agglomerated in the form of catkins and contains a large amount of synthetic resin dust. FRP regenerated fibers are fluffy and agglomerated like cotton, and the length is between 3mm and 15mm; 37 parts of sieved waste asphalt concrete, 13 parts of recycled FRP fiber, 17 parts of fly ash and 17 parts of lime powder were weighed according to the ratio. Then regenerated fiberglass, fly ash and lime powder are mixed for 4 minutes, then waste asphalt concrete is added for seco...

Embodiment 2

[0035] First, the waste asphalt concrete is crushed to destroy the cementation of asphalt between the aggregates to form a single-grain structure of asphalt wrapped around the aggregates, and then sieved, and the particle size of the waste asphalt concrete obtained after sieving is between 3 and 5mm; The FRP waste is cut into small pieces, and then the small pieces of FRP waste are crushed by crushing equipment to obtain FRP regenerated powder and FRP regenerated fiber. The FRP regenerated powder is fluffy and agglomerated in the form of catkins and contains a large amount of synthetic resin dust. FRP regenerated fibers are fluffy and agglomerated like cotton, and the length is between 3mm and 15mm; according to the ratio, weigh 30 parts of waste asphalt concrete after sieving, 15 parts of recycled FRP fiber, 15 parts of fly ash and 20 parts of lime powder. Then regenerated fiberglass, fly ash and lime powder are mixed for 3 minutes, then waste asphalt concrete is added for sec...

Embodiment 3

[0038] First, the waste asphalt concrete is crushed to destroy the cementation of asphalt between the aggregates to form a single-grain structure of asphalt wrapped around the aggregates, and then sieved, and the particle size of the waste asphalt concrete obtained after sieving is between 3 and 5mm; The FRP waste is cut into small pieces, and then the small pieces of FRP waste are crushed by crushing equipment to obtain FRP regenerated powder and FRP regenerated fiber. The FRP regenerated powder is fluffy and agglomerated in the form of catkins and contains a large amount of synthetic resin dust. FRP regenerated fibers are fluffy and agglomerated like cotton, and the length is between 3mm and 15mm; according to the ratio, weigh 45 parts of waste asphalt concrete after sieving, 10 parts of recycled FRP fiber, 20 parts of fly ash and 15 parts of lime powder. Then regenerated fiberglass, fly ash and lime powder are mixed, mixed for 5 minutes, then waste asphalt concrete is added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com