Preparation method and application of inorganic/organic composite hydrogel driver

A hydrogel driver and hydrogel technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve problems such as difficult precise control, complicated operation, and limited cycle deformation, and achieve the effect of fast bending rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

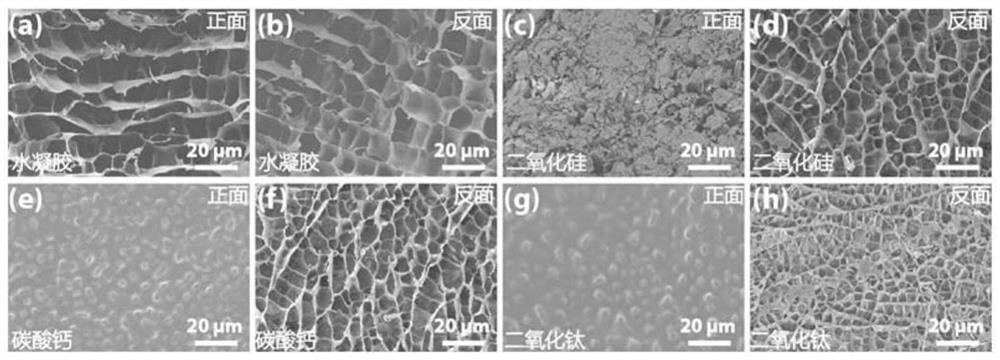

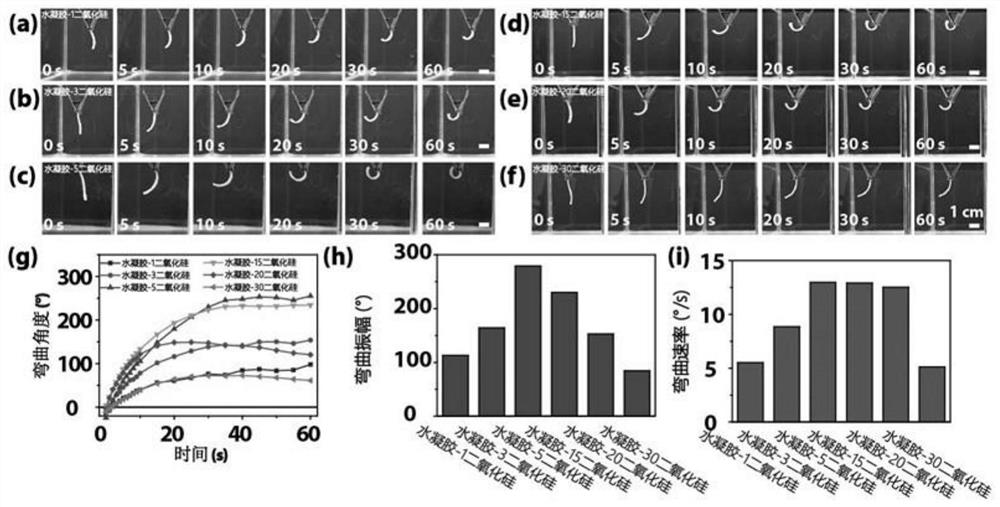

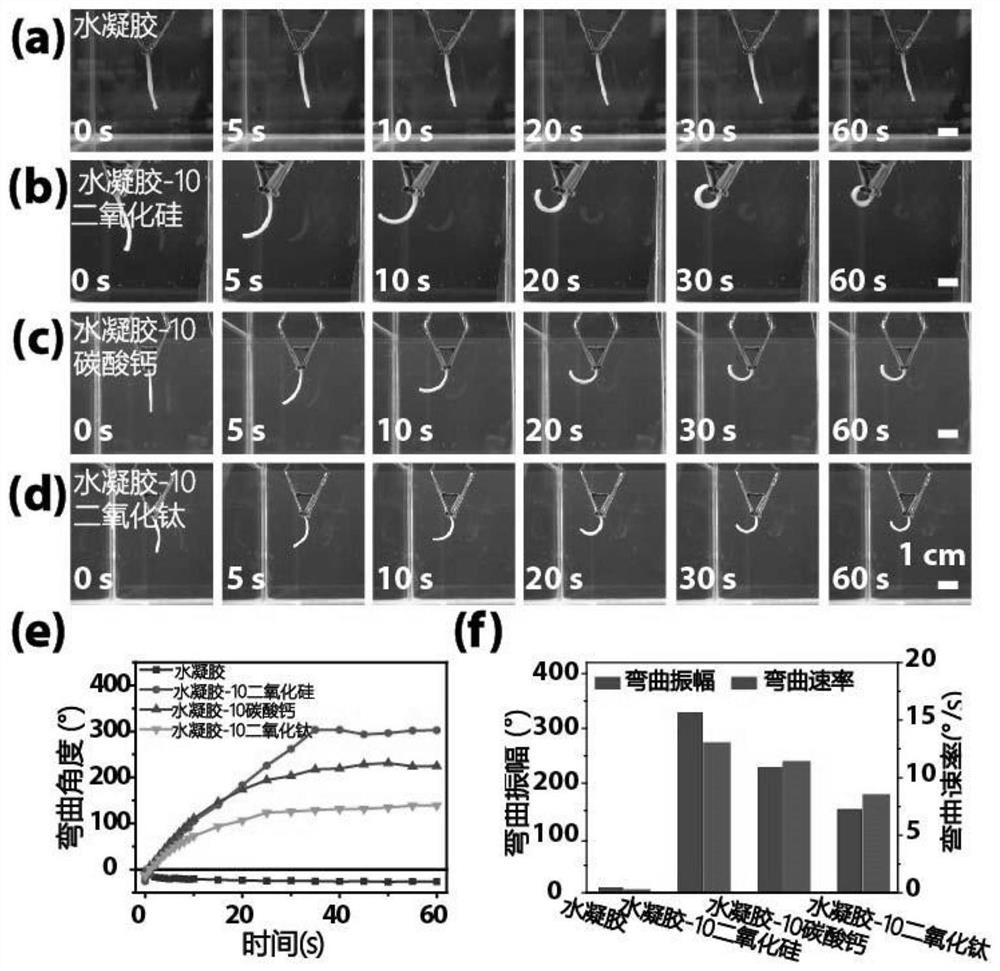

[0026] Inorganic / Organic Composite Hydrogel Actuator PNIPAM-SiO 2 Preparation of:

[0027] Step (1), preparation of hydrogel prepolymerization solution: add 1.14g XLG type synthetic magnesium lithium silicate into 50mL deionized water and seal and stir for 2 hours to obtain a suspension, and simultaneously add 0.226g 1-hydroxycyclohexylphenyl Add ketone to 10mL methanol to prepare an initiator solution, then add 5.65g monomeric N-isopropylacrylamide and 0.5mL initiator solution to the suspension in turn, stir for 2 hours at room temperature in the dark, and finally pour into the solution Introduce high-purity nitrogen gas bubbles to remove the dissolved oxygen contained in the solution to obtain a transparent (N-isopropylacrylamide)-clay hydrogel pre-polymerization solution;

[0028] Step (2), the preparation of inorganic dispersion liquid: the SiO of 1g 2 Add in deionized water, ultrasonically disperse the inorganic particles evenly, and prepare a 200mL dispersion with a co...

Embodiment 2

[0032] Inorganic / Organic Composite Hydrogel Actuator PNIPAM-TiO 2 Preparation of:

[0033] Step (1), preparation of hydrogel prepolymerization solution: add 1.14g XLG type synthetic magnesium lithium silicate into 50mL deionized water and seal and stir for 2 hours to obtain a suspension, and simultaneously add 0.226g 1-hydroxycyclohexylphenyl Add ketone to 10mL of methanol to prepare an initiator solution, then add 5.65g of monomeric N-isopropylacrylamide and 0.5mL of the initiator solution to the suspension in sequence, stir for 2 hours in the dark at room temperature, and finally pour into the solution Into high-purity nitrogen bubbling, remove the dissolved oxygen contained in the solution, obtain transparent (N-isopropylacrylamide)-clay hydrogel prepolymer liquid;

[0034] Step (2), the preparation of inorganic dispersion liquid: the TiO of 1g 2 Add in deionized water, ultrasonically disperse the inorganic particles evenly, and prepare a 200mL dispersion with a concentra...

Embodiment 3

[0038] Inorganic / organic composite hydrogel actuating PNIPAM-CaCO 3 preparation method

[0039] Step (1), preparation of hydrogel prepolymerization solution: add 1.14g XLG type synthetic magnesium lithium silicate into 50mL deionized water and seal and stir for 2 hours to obtain a suspension, and simultaneously add 0.226g 1-hydroxycyclohexylphenyl Add ketone to 10mL methanol to prepare an initiator solution, then add 5.65g monomeric N-isopropylacrylamide and 0.5mL initiator solution to the suspension in turn, stir for 2 hours at room temperature in the dark, and finally pour into the solution Introduce high-purity nitrogen gas bubbles to remove dissolved oxygen contained in the solution; obtain a transparent (N-isopropylacrylamide)-clay hydrogel prepolymer;

[0040] Step (2), the preparation of inorganic dispersion liquid: the CaCO of 1g 3 Add in deionized water, ultrasonically disperse the inorganic particles evenly, and prepare a 200mL dispersion with a concentration of 5m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com